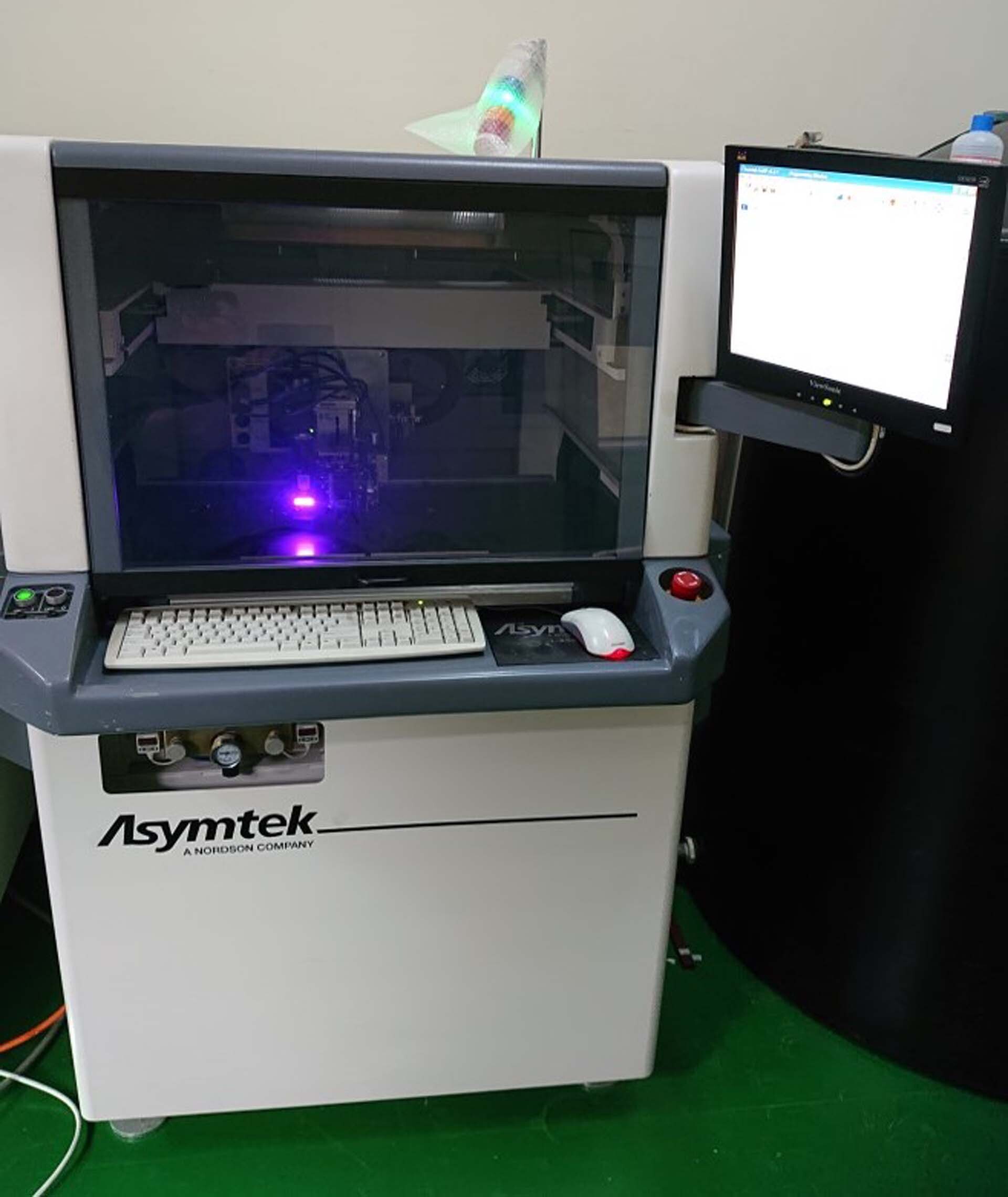

Used ASYMTEK X-1010 #9407901 for sale

URL successfully copied!

Tap to zoom

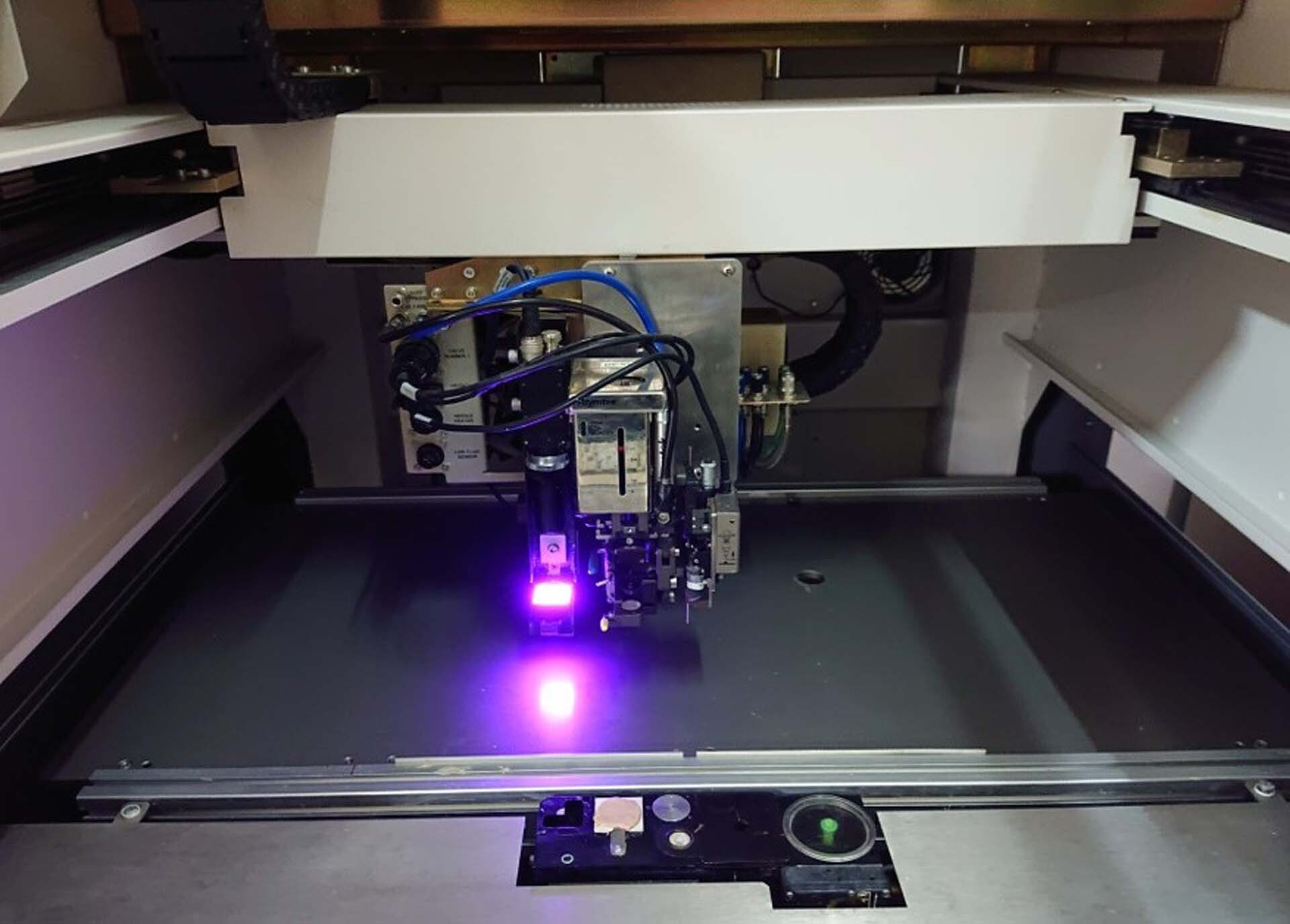

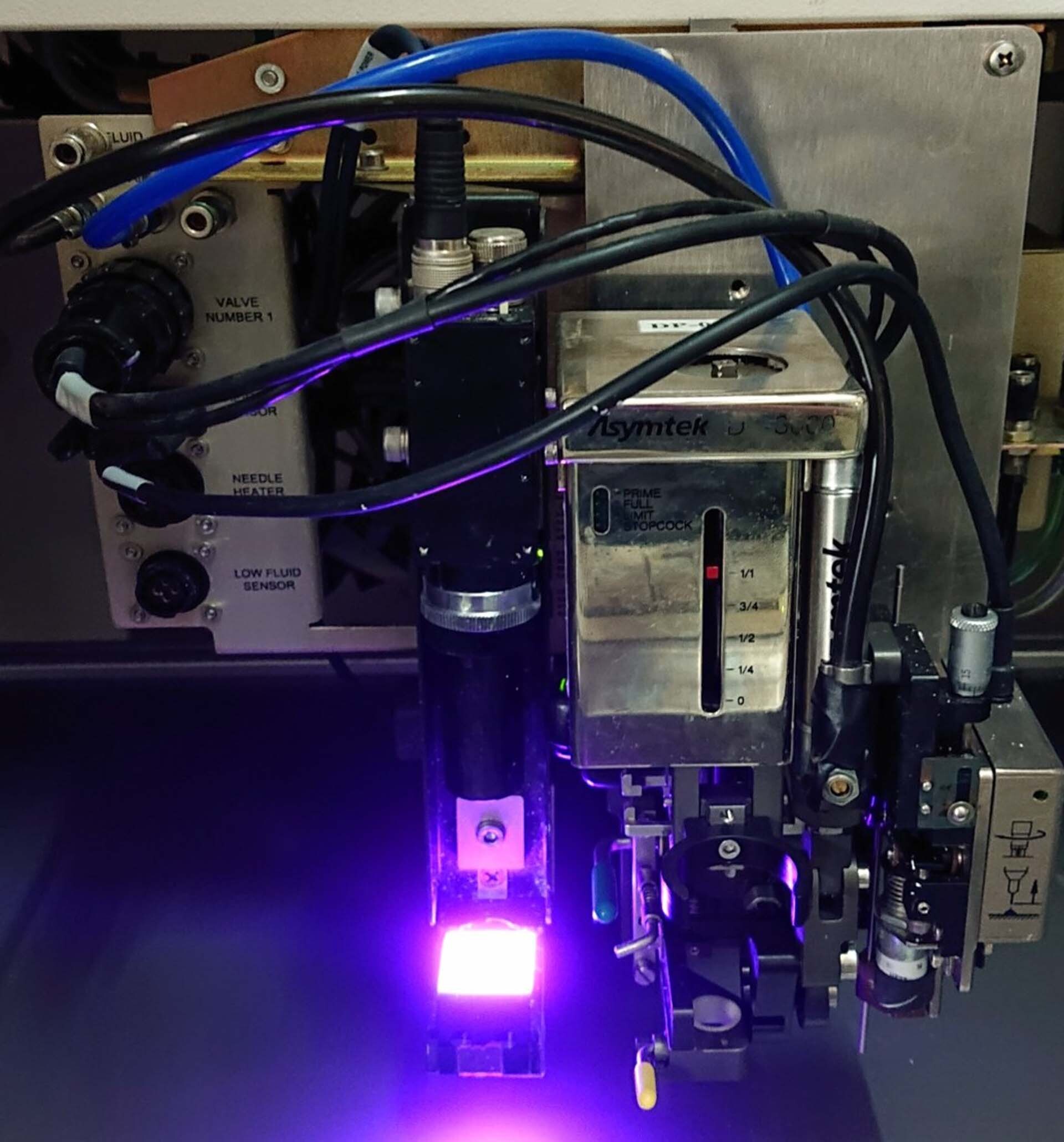

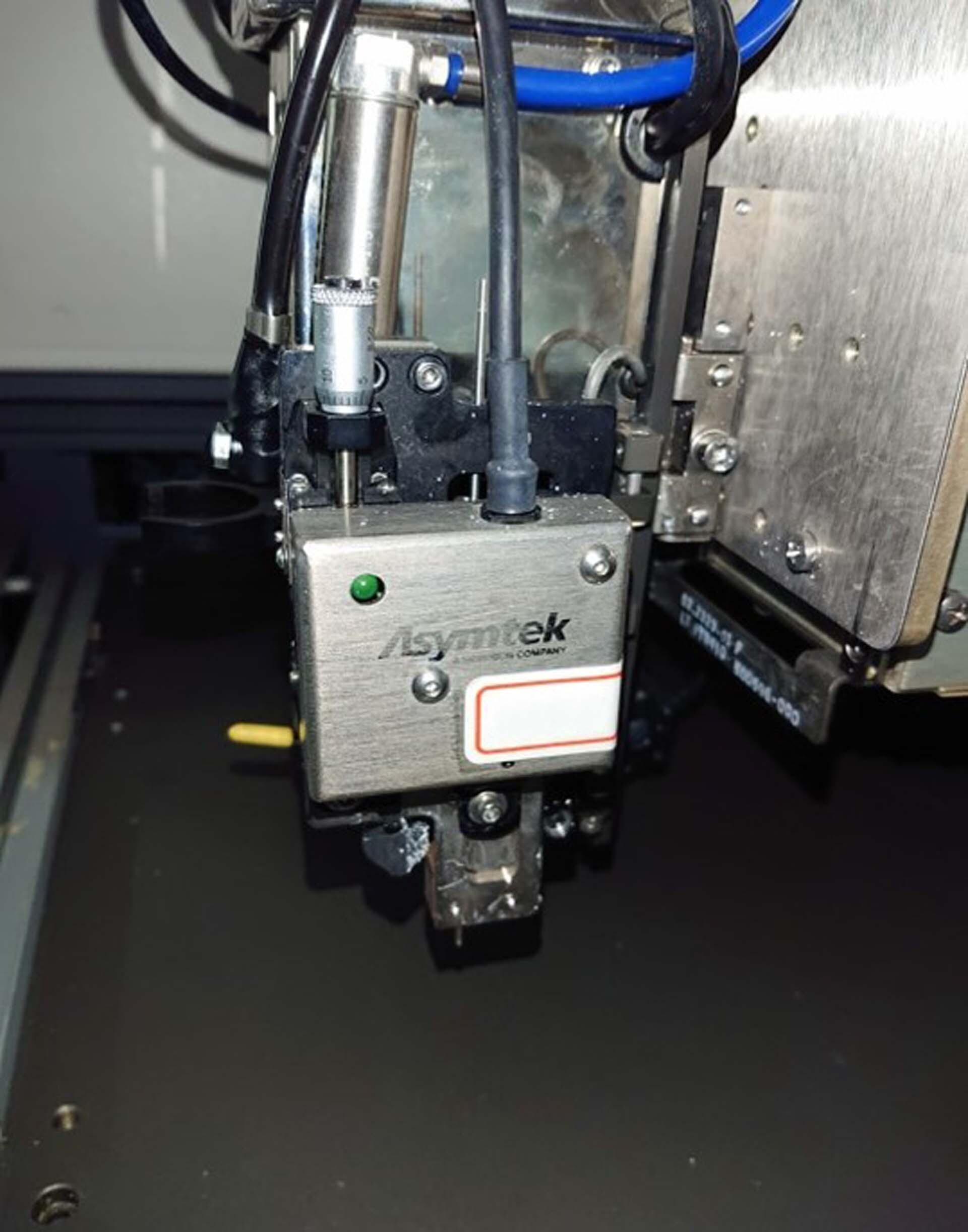

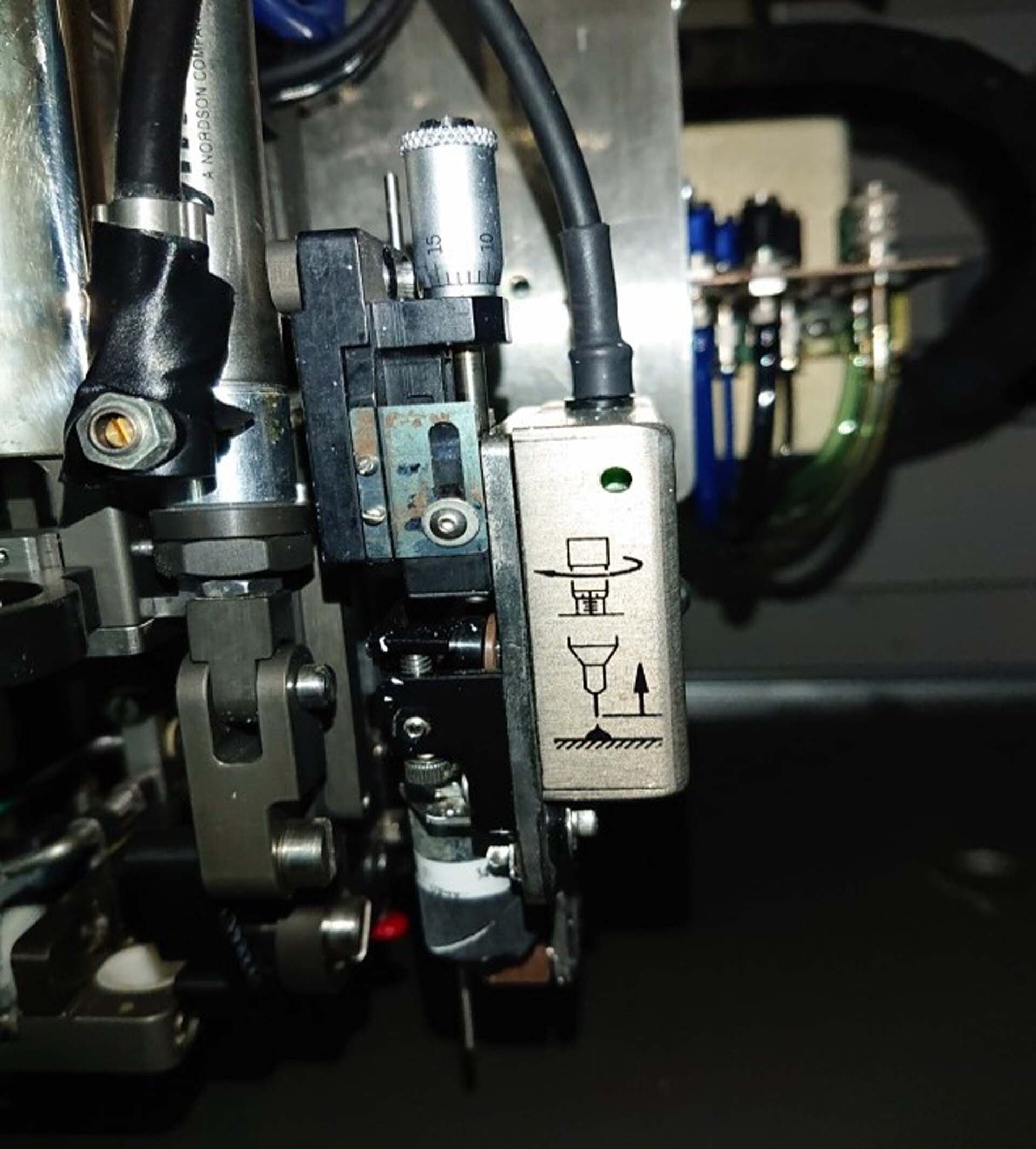

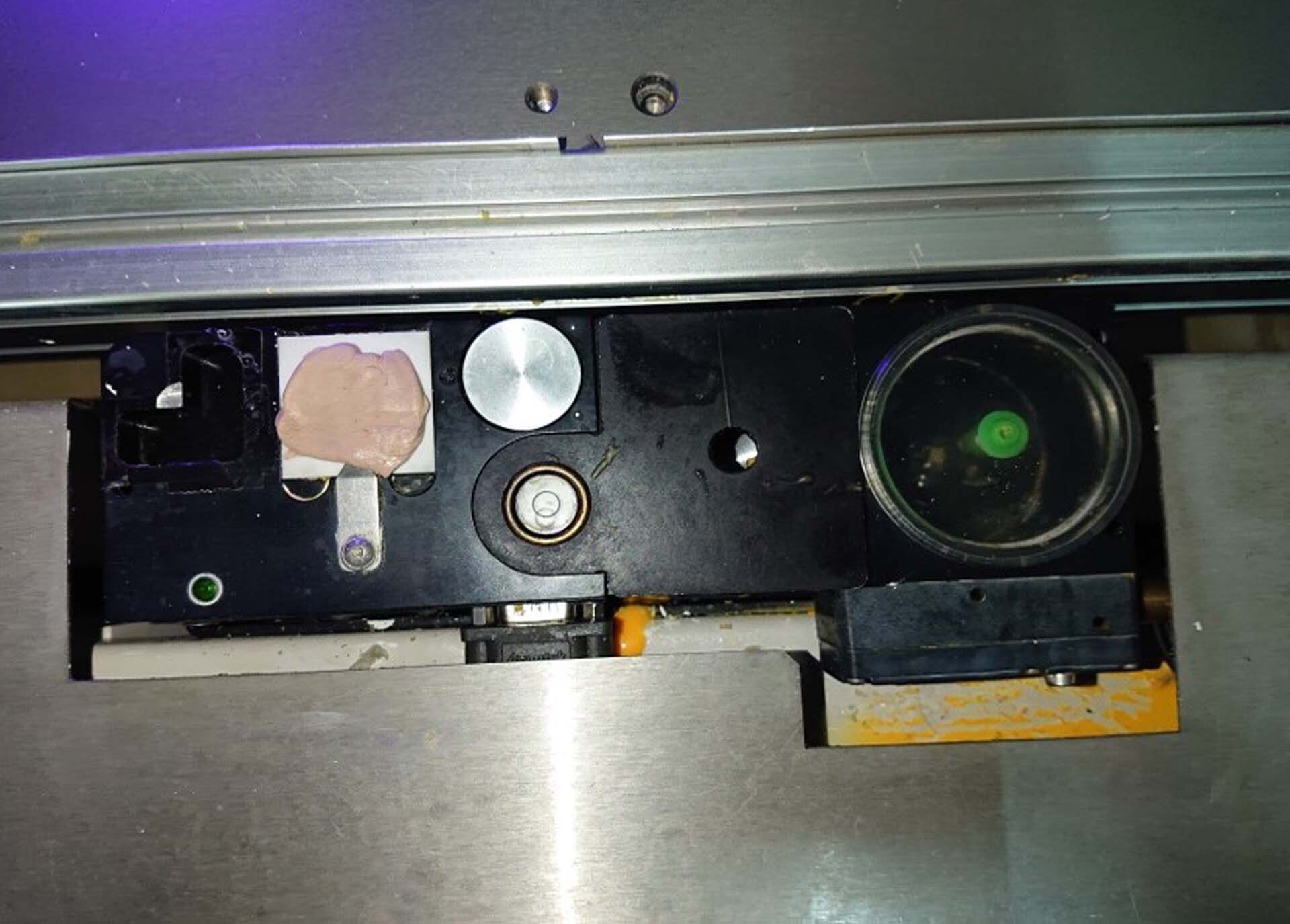

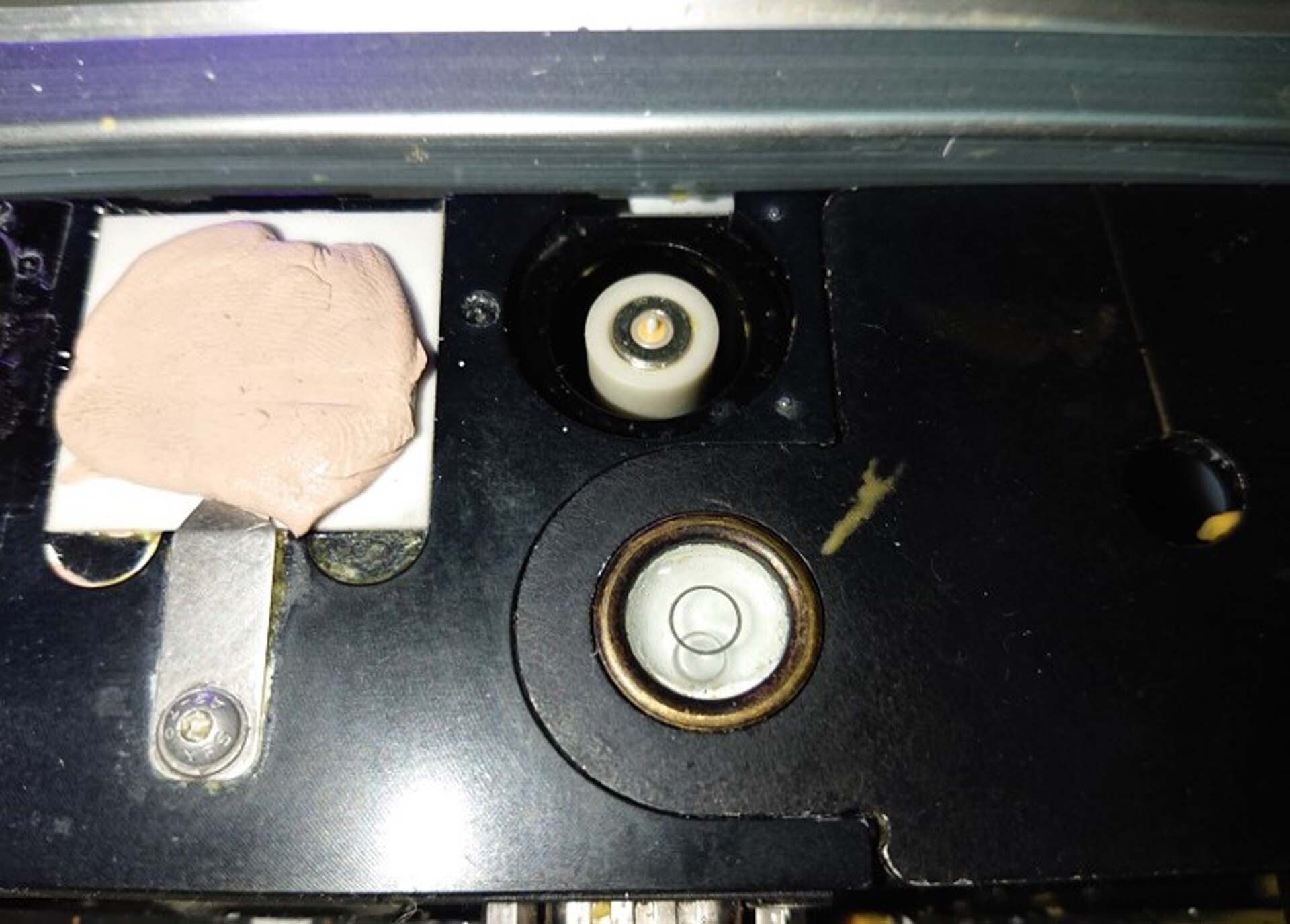

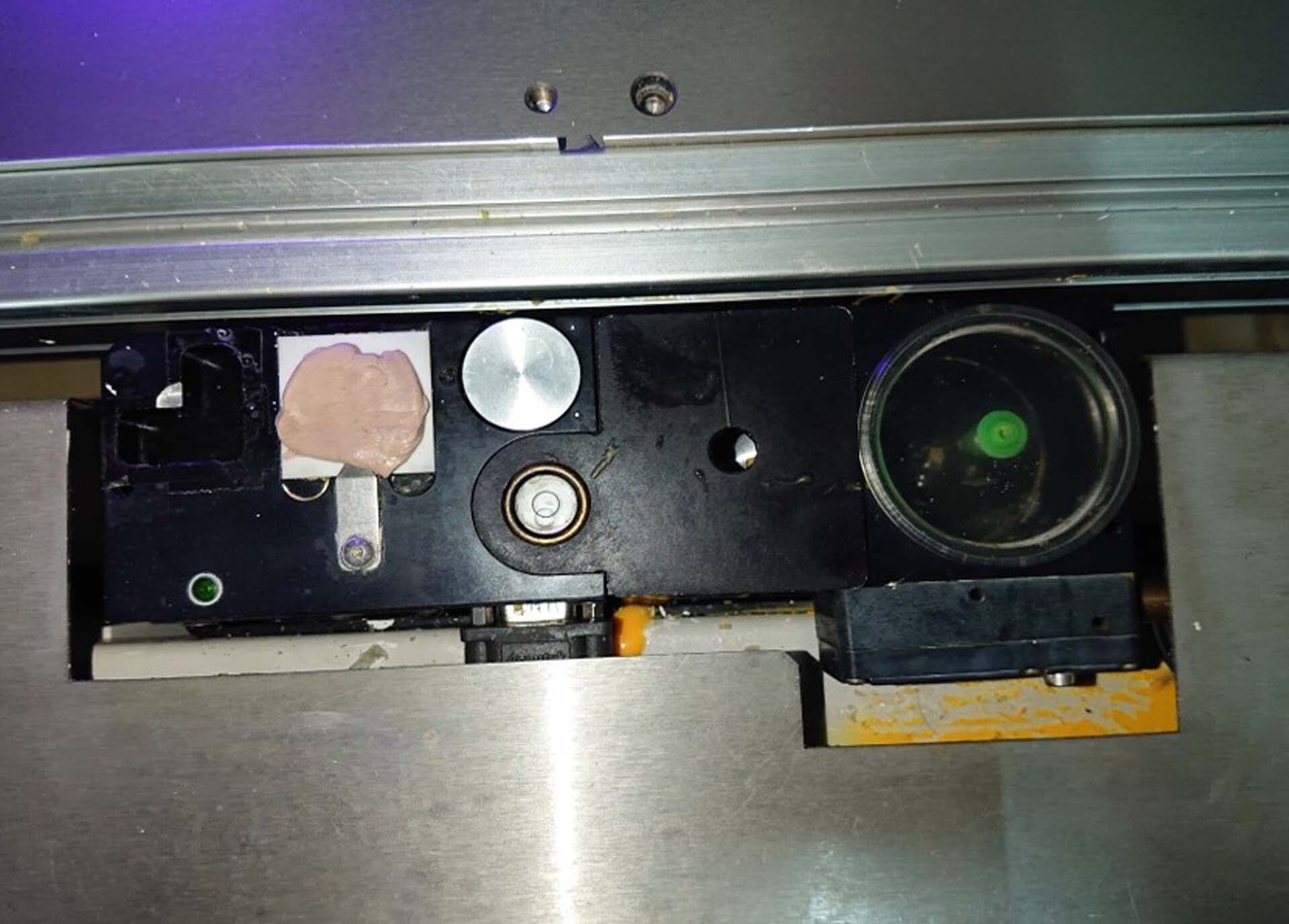

ASYMTEK X-1010 is an advanced, high-performance PC board assembly and manufacturing equipment that is ideal for mid- to high-volume applications. It is designed to provide maximum throughput, precision placement accuracy and unmatched flexibility for manufacturers seeking to maximize efficiency, quality and performance. ASYMTEK X 1010 offers an integrated solution for automated assembly, SMT, THT, nontraditional processes, and other special assembly requirements. The multifunctional system is capable of carrying out multiple components placements and process steps in a single unit. It is equipped with a high-speed, multi-axis motion machine with a large working area and adjustable z-height allowing for precision placement of components of all sizes and shapes. It has a reliable pick-and-place tool that can handle up to 3,000 components per hour with applications that include placing connectors, spring-loaded contacts, and flatwound components. It also has vision asset technology with real-time camera input to ensure precision of components after soldering. X-1010 also offers several advanced inspection capabilities such as defect and presence detection, pattern recognition, vision measurement, online NPI monitor, and Component Tracking Model. Additionally, its high precision placement accuracy ensures enhanced repeatability and accuracy of components placement coupled with superior accuracy of vision Inspection for efficient and high-yield assembly. The equipment has an open architecture design that allows for easy assembly configuration changes and expansions, to help manufacturing lines keep pace with changing products. The easy-to-use graphical user interface (GUI) of X 1010 facilitates effortless system set up and operation. It also has a large color LCD display panel and an overhead mounted operator station monitor to monitor machine performance. ASYMTEK X-1010 provides an automated solution that is reliable and cost-effective for high-volume manufacturing applications. It utilizes state-of-the-art technology to deliver high precision, speed and excellent repeatability in order to increase productivity, quality and throughput.

There are no reviews yet