Used ASYMTEK X-1020 #293596930 for sale

URL successfully copied!

Tap to zoom

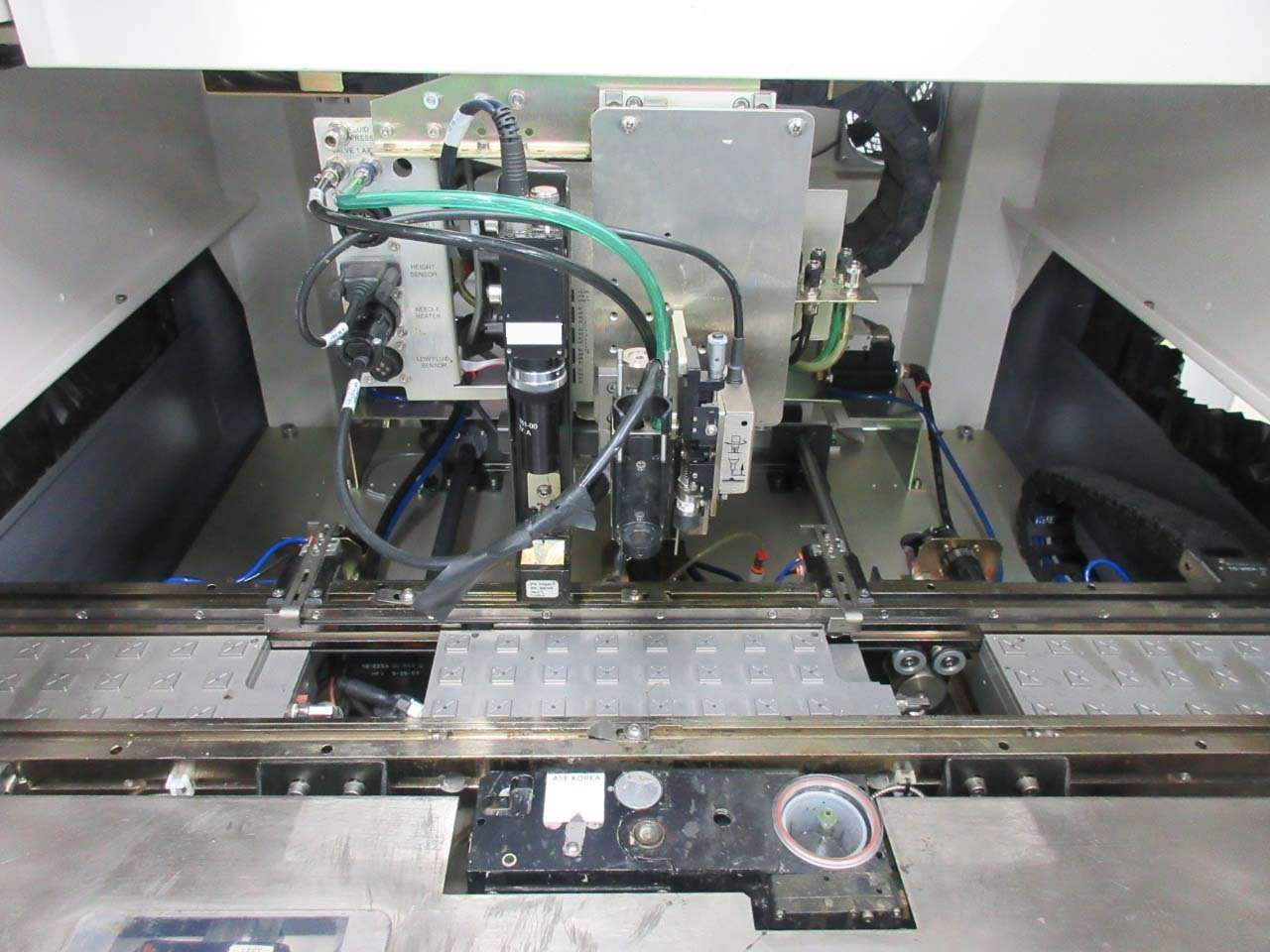

ASYMTEK X-1020 is a fully automated PC Board Assembly and Manufacturing Equipment designed to maximize throughput, accuracy, and repeatability in the production of PC Boards. The robust, modular design of the system simplifies component placement, soldering, and testing operations to enable precise and precise control. The unit is equipped with a pick and place component that can handle single devices ranging in size from 0.5 to 9.0 mm up to an overall area of 40mm x 40mm. The component placement is controlled by an integrated vision machine and the placement accuracy is +/- 25 microns. The tool also includes an alternating-current ultrasonic soldering head that allows for solder joints to be accurately welded with respect to the component. This feature minimizes the solder fumes and improves production yield with minimal errors. ASYMTEK X1020 features a multi-function soldering head that combines spray fluxing, wave soldering, and solder paste application capabilities into a single head, allowing for faster throughput and improved accuracy. This head applies even amounts of fluxing and solder paste using spray and wave technology, resulting in highly reliable soldered joints. Additionally, the two selectable temperature zones on the integrated ovens can be adjusted for different soldering applications. To further ensure quality and reliability of the finished product, X 1020 includes a precision digital imaging asset (DID) inspection unit. This detects component anomalies such as misalignments, height differences, solder-joint defects, missing or incorrect components, etc. ASYMTEK X 1020 model also comes with a PC-based Windows operating equipment, Industrial Network Architecture (INA), System Controller, touch panel with unit-level keypad and PC, and monitoring software. This allows users to access the machine status, run the machine, and monitor production via a number of interfaces. It also includes advanced IPC-compliant Fast Setup and Fast Change Software for easy loading and unloading of product data and changeovers. Ultimately, X1020 is designed to maximize your efficiency and accuracy in PC Board Assembly and Manufacturing. With its robust features, such as reliable component placement, uniform flux and solder paste application, accurate soldering, and highly precise inspection unit, the tool ensures consistent high-quality results when producing PC Boards.

There are no reviews yet