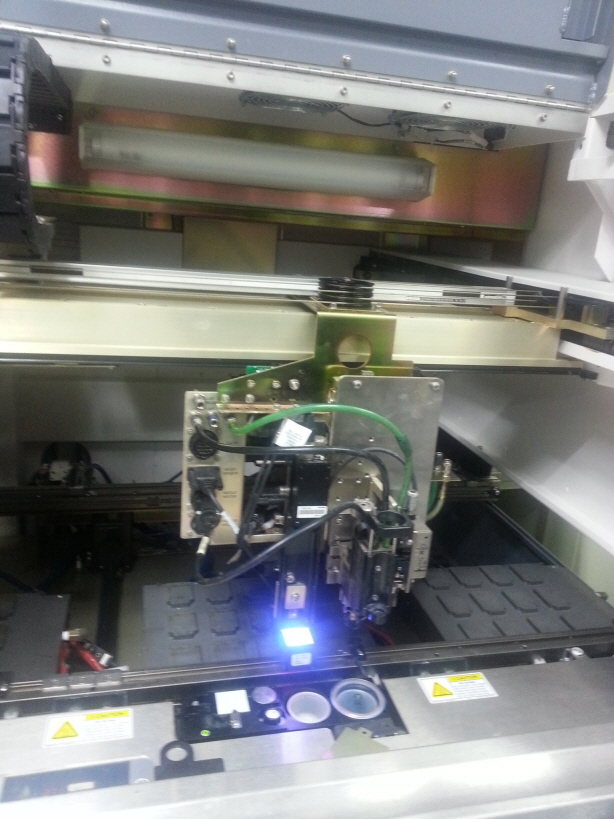

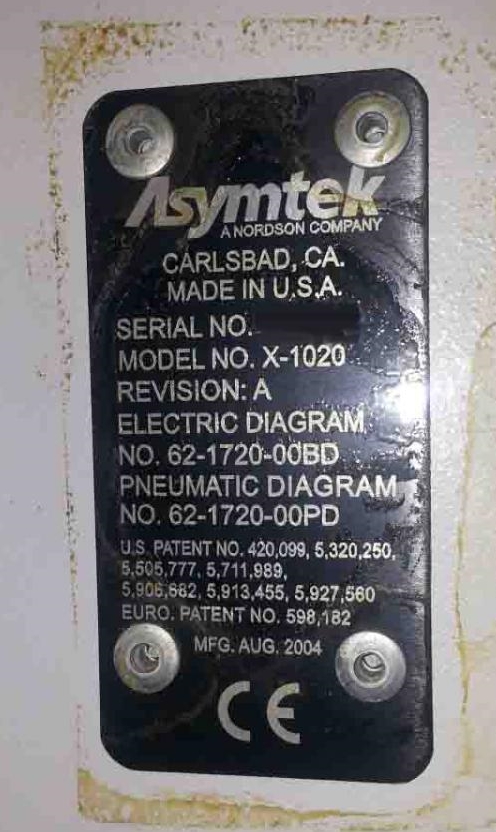

Used ASYMTEK X-1020 #9066765 for sale

URL successfully copied!

Tap to zoom

ID: 9066765

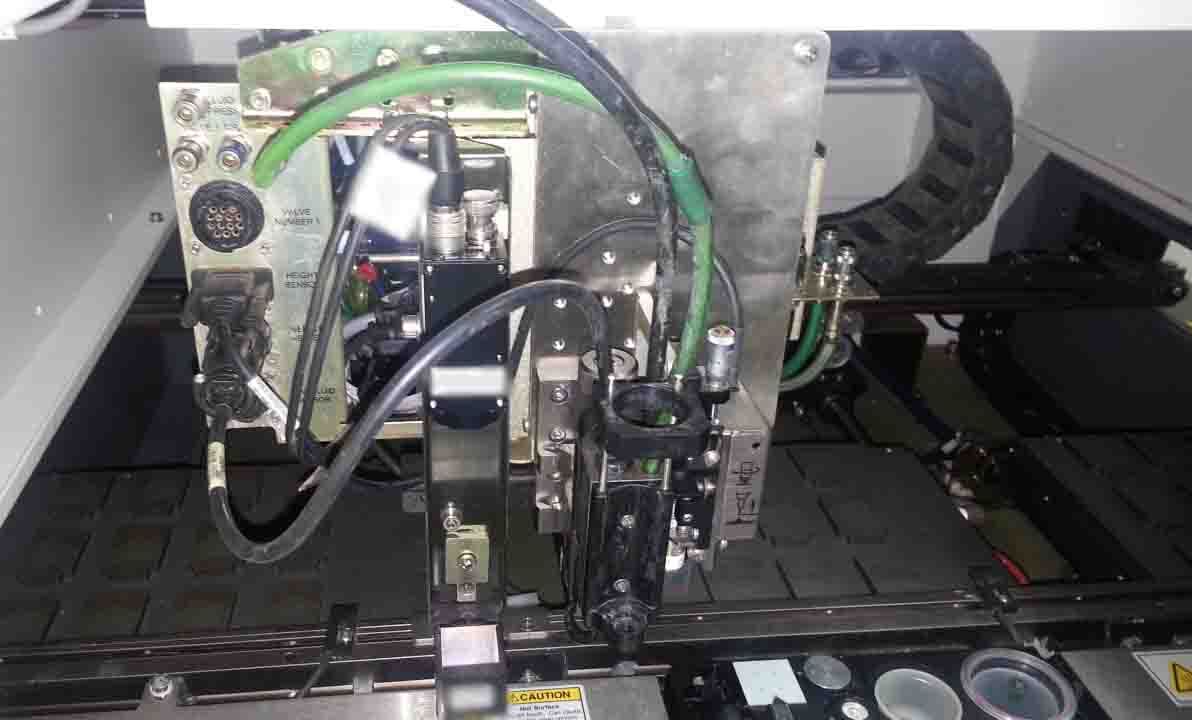

Dispensing system

Air jet valve for dispensing

Specifications:

Motion system

X-Y Placement accuracy

±0.050 mm (0.002"), 3 Sigma

±0.076 mm (0.003"), 3 Sigma (fast mode)

Z Accuracy: ±0.025 mm (0.001"), 3 Sigma

High precision Z accuracy: ±0.012 mm (0.0005"), 3 Sigma

X-Y Repeatability: ±0.025 mm (0.001")

Encoder resolution: 5 micrometer

X-Y Acceleration: 1.0 g peak with s-curve jerk control

X-Y Velocity: 1 m/s (40 in/s) peak

X-Y Travel (with DJ-9000): 468.0 x 458.0 mm (18.4 x 18.0")

Z Travel: 89.0 mm (3.5")

Dispense area (X-Y):

DJ-9000, DV-8K, DV-7K: 458.2 x 459.0 mm (18.0 x 18.1")

DP Pump: 442.2 x 418.6 mm (17.4 x 16.5")

Dual action (Valve 1/Valve 2):

DV or DJ/DV or DJ: 356.9 x 432.5 mm (14.1 x 17.0")

DV or DJ/DP: 353.0 x 394.2 mm (13.9 x 15.5")

DP/DP: 309.0 x 394.2 mm (12.2 x 15.5")

Vision and lighting:

Lighting: On-axis Red / Blue LED with 255 independent light levels

Image size: 12.7 mm (0.5") standard

Conveyor:

3-Station o-ring

SMEMA-Compatible: Height adjustable between 891.0 to 965.0 mm

Width-adjustment: Motorized, variable 19.0 to 459.7 mm

800 MHz with 80 GB hard drive

256 MB RAM

User interface:

LCD flat-panel display, 12.1"

ASCII Keyboard / Mouse

10-100 MBS twisted pair ethernet

DVD ± RW

USB Port

OS: Windows XP

Facility requirements:

Air supply: 621 kPa (6.1 atm, 90 psi)

Power: 180-260 VAC, single phase, 30A, 50-60 Hz

2004 vintage.

ASYMTEK X-1020 is a next generation PC board assembly and manufacturing equipment specifically designed for high-end, mixed technology electronic device production. It features a single PC board size capability, an eight feeder station capacity, and a minimum component size of 0201 metric. The system is highly automated and features independent PCB motion for the most efficient soldering operation. It has a maximum speed of 10,000 CPH and a maximum board size of 12" x 12". ASYMTEK X1020 is equipped with a full range of interchangeable placement heads which can accept components from 0201 metric up to 84mm square. The unit is able to accommodate a large variety of component packages and substrates, providing maximum flexibility for design implementation. Additionally, the machine offers off-line programming for easy job set-ups and speedier design changes. To ensure precise repeatability and accuracy, X 1020 uses a three-position alignment process. This aligns components with higher accuracy, improving equipment throughput and increasing first-pass yield rates. The tool is also equipped with vision-based component verification that reduces false reject rates and improves quality. X-1020 is designed with a 64-bit, Intel-based industrial computer that provides high-speed communication with the asset. This allows for a variety of computer aided design (CAD) file formats including Gerber, Excellon, and GenCAM. Powerful software provides users with the flexibility to easily integrate the model into their existing production environment. Set-up and operation is simplified with a graphical user interface that provides operators with all the information they need in a single viewing window. The advanced production control equipment also allows for easy job set-up, production tracking and results analysis. X1020 is designed to be efficient, flexible and reliable. This system is able to increase production performance and efficiency while providing the highest quality product soldering available today. This makes it the ideal choice for high-end, mixed technology electronic device production.

There are no reviews yet