Used ASYMTEK X-1020 #9101322 for sale

URL successfully copied!

Tap to zoom

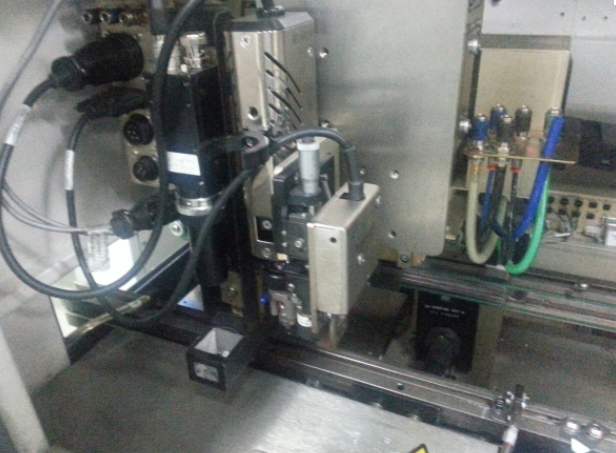

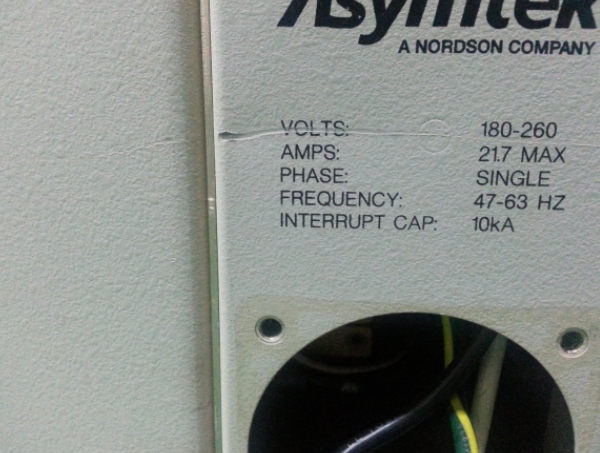

ASYMTEK X-1020 is a pc board assembly and manufacturing equipment that utilizes a five-axis pick-and-place head to provide precise placement accuracy. This system can fulfill any production need, from low-volume prototyping to high-volume production runs. ASYMTEK X1020 utilizes a unique combination of software pre-configured with all processing parameters, providing the user with a fast and accurate solution. X 1020 also offers a comprehensive range of vision algorithms and techniques, which can easily be configured for any specific board component. ASYMTEK X 1020 integrates a pick-and-place platform, utilizing multiple software-driven vision systems. This allows for fast and accurate placement of components onto pc boards and complex assemblies. X-1020 is capable of placing any component, from tiny 0402 components up to large packages such as BGA. This unit is also capable of placing components within ±0.0015" accuracy and offers ultra-precise placement accuracy of within ±0.0006". X1020 is a fully loaded machine with features such as board clamps and integrated conveyor systems designed to improve productivity and improve accuracy. It also features an integrated nozzle cleaning tool, component bin sensors and an integrated flow through boardfixture to help minimize setup times. The asset is also compatible with software and hardware from a range of vendors, allowing for easy integration into any automated manufacturing model. ASYMTEK X-1020 is a versatile equipment that can handle any job, from low-volume prototyping to high-volume production runs. With its large component range, precise component placement accuracy and integrated features, it is an ideal choice for any pc board assembly and manufacturing needs.

There are no reviews yet