Used ASYMTEK X-1020 #9101323 for sale

URL successfully copied!

Tap to zoom

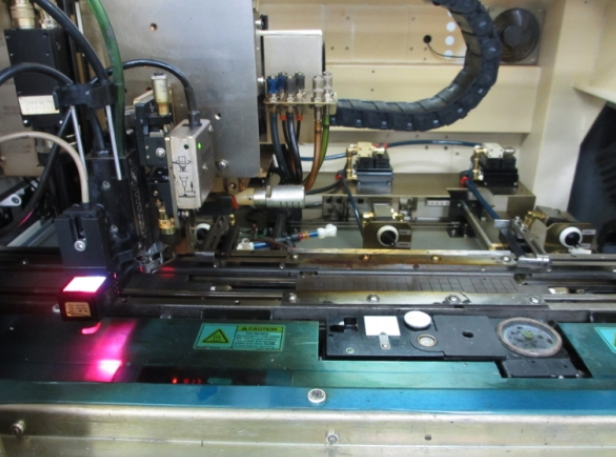

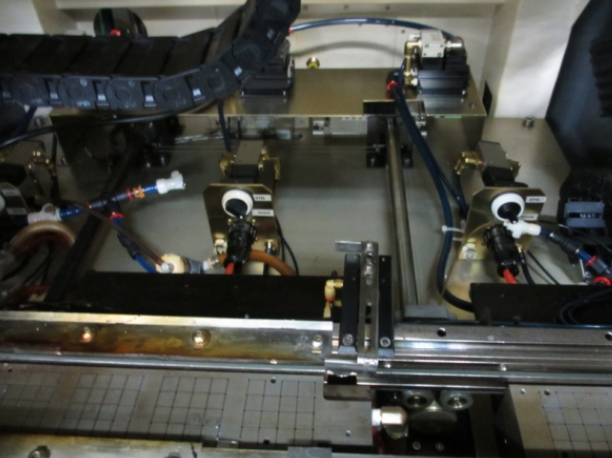

ASYMTEK X-1020 PC Board Assembly and Manufacturing equipment is a state-of-the-art solution that enables high-volume production, with faster turnaround and higher accuracy. The system allows for precise assembly and manufacturing of complex PC boards with automatic component placement, testing, cleaning, and solder re-flow processes. The unit's flexibility allows operation for various assembly types, including wave soldering, double-sided reflow, single- or multi-sided board loading. ASYMTEK X1020 is equipped with a variety of cold and hot air nozzles to automatically detect and place a wide range of component sizes for consistent precision. The machine includes sensitive vision systems for quality assurance that can detect surface mount errors, shorts, lifted leads, solder bridge connections, and misalignments. It is capable of tracking assembly status of all components with an offline part-mark recognition tool. X 1020 can also be programmed for fast response and accuracy. ASYMTEK X 1020 features integrated robots and sub-systems for automated material handling. It is capable of handling PCBs with a weight up to 500g and a size of maximum 550x550mm. Its integrated automated material handling capabilities provide quick and reliable material transport to and from the application station. The asset comes with an easy-to-use touch screen user interface for real-time monitoring and control. It has self-diagnostics features for preventive maintenance, and includes a network data archiving function that enables historical data recording and traceability. X-1020 is a reliable, flexible, and robust model that has been designed to streamline the workflow and improve the efficiency of PC board assembly. With its comprehensive assembly and manufacturing capabilities, it is an ideal equipment for high-volume production and high-precision assembly of PC boards.

There are no reviews yet