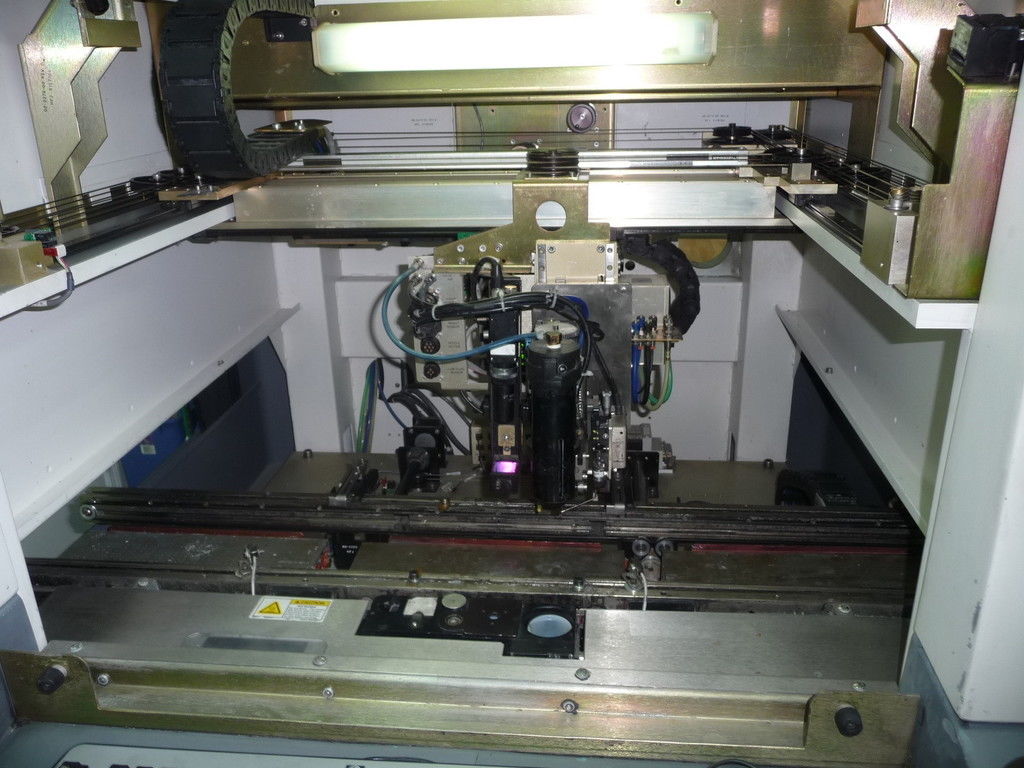

Used ASYMTEK X-1020 #9101917 for sale

URL successfully copied!

Tap to zoom

ID: 9101917

Vintage: 2004

Dispensing system

DP-3000 linear positive displacement pump

Closed-loop control of process variables: fluid weight, flow rate, and substrate heat

Enhanced pattern recognition system with blue-red on-axis lighting

Linear-encoded X-Y drive system: Placement accuracy: +/-0.050mm high-precision; Application speed: +/-0.076mm

Dispense area with DP Pump: 442.2mm x 418.6mm (17.4" x 16.5")

Power (Mains): adaptive power supply that accomodates supply voltages between 200-240 VAC, single phase, 30A, 50/60 Hz

Air Supply: 621 kPa (6.2 Bar, 90 psi)

2004 vintage.

ASYMTEK X-1020 is a fully automated 'pc board assembly and manufacturing' equipment designed with the versatility to handle large assortment of applications. It is suitable for prototyping, high-volume production, and quick turn applications associated with component mounting, inspection and placement verification. ASYMTEK X1020 has a stable Dual Gantry design that enables its robust placement stability, precision and high-speed repeatability. This ensures that precise component mounting configurations can be achieved in the shortest possible time. It is equipped with a broad component range allowing the system to operate with a variety of component sizes, ranging from 0201s to larger package-types, including odd-shape components, as well as connectors and large ICs up to a height of 24mm. X 1020 also offers component placement rates of up to 15,000 cph. X1020 is computer-controlled and can easily be integrated into other PC board assembly and manufacturing systems, including production-yielding features and optional automation systems. It is equipped with an integral Vision Inspection Unit (IVS) that provides real-time component inspection and verification for all component placements. Additionally, the machine is equipped with an automatic tool cleaning function that keeps the machine clean even when running delicate materials, such as lead-free solders or fluxes. X-1020 also offers flex placement options, enabling the user to customize the tool to best suit their production needs. Optional placement heads, such as Z-axis, W-axis and Theta-Axis can be added in order to accommodate components requiring special placement configurations. Furthermore, optional equipment, such as conveyors, handling tools and other add-ons can be configured to fit unique production requirements. ASYMTEK X 1020 is a user-friendly asset, providing intuitive menu-driven software that is easy to use and configure. It is also easy to maintain, with a built-in self-diagnostic model that ensures optimal performance, and an LED based indicator equipment that provides a visual guide to system status, reducing machine downtime and optimizing production runs. In short, ASYMTEK X-1020 is a cost effective and efficient unit for PC board assembly and manufacturing, offering users a versatile and high-performance solution for a range of particular applications. Its Dual Gantry design, broad component range, improved placement technology and highly efficient software combine to make this machine an ideal choice for both small-scale and high-volume production processes.

There are no reviews yet