Used ASYMTEK X-1020 #9193447 for sale

URL successfully copied!

Tap to zoom

ID: 9193447

Vintage: 2006

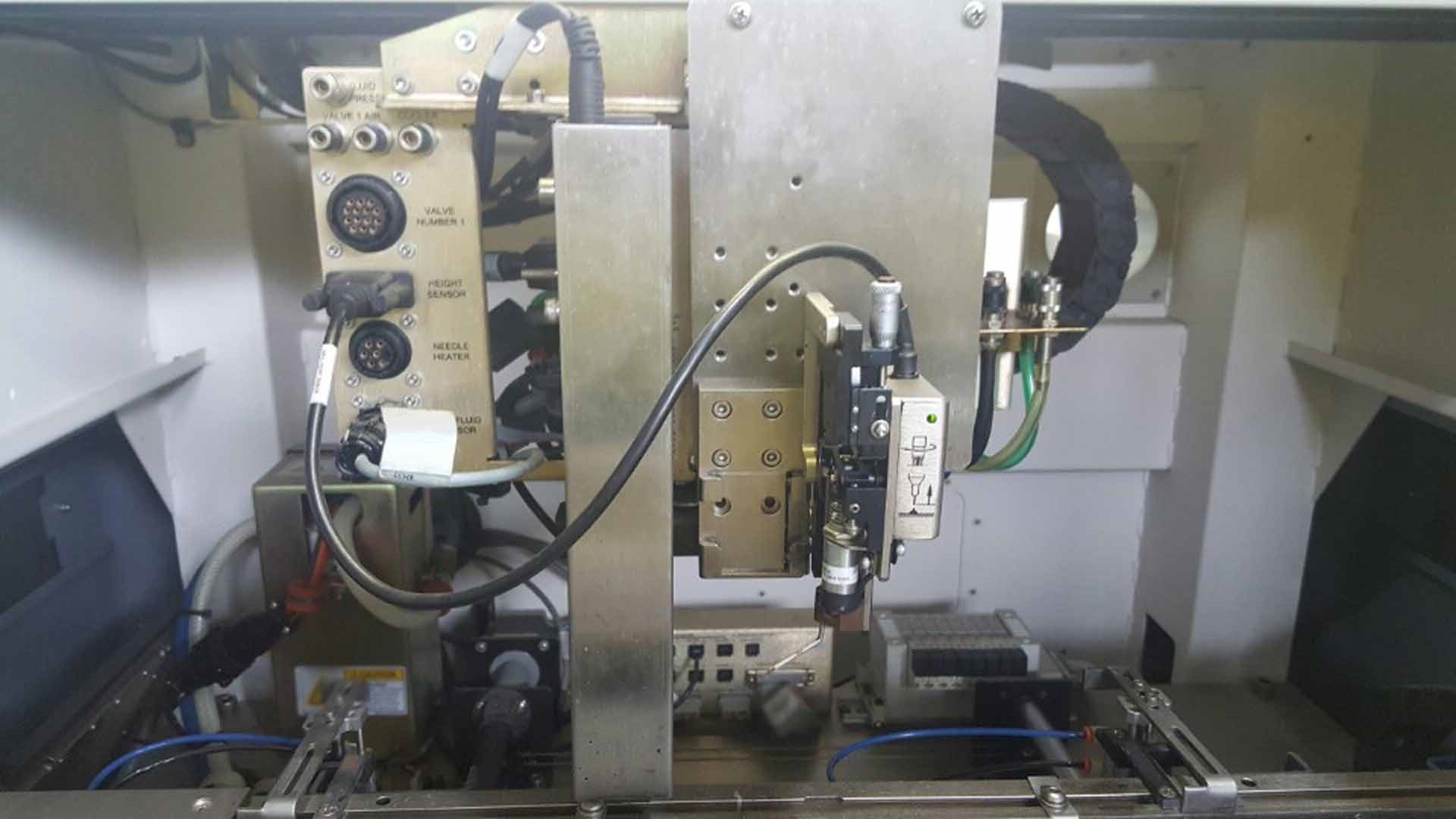

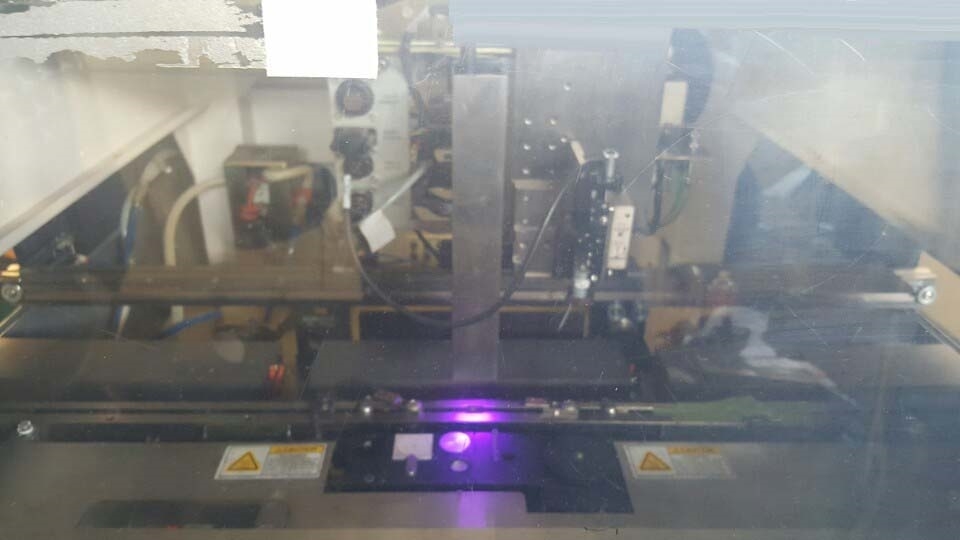

Dispensing / Coating system, part machine

DJ9000 Pump

2006 vintage.

ASYMTEK X-1020 is a fully automated equipment designed for PC board assembly and manufacturing. It is designed to merge high reliability, modularity, and high performance technology with user interface and software advancements. The system's modular design makes it incredibly user-friendly and easy to maintain. It integrates a dual gantry unit that provides unsurpassed positioning accuracy and speed for both assembly and inspection operations. ASYMTEK X1020's hardware includes robotic hands, vision-guided robots and inspection tools, along with pick-and-place assembly operations for quick and efficient production of complex PCBs. It also includes integrated pressurized liquid dispenser (IPLD) technology for fast and precise application of fluxes, adhesives and solder paste. The machine also offers an intuitive graphics interface and user-friendly software tools for both manufacturing and quality assurance. It is designed to optimize yield, cycle time and tool throughput while ensuring product quality. Supported by predictive analytics and advanced fault monitoring, X 1020 can identify potential issues before they occur. With its ability to process up to 10 PC boards simultaneously, it is ideal for high-volume production operations. X-1020 also integrates an easy-to-use touch panel interface that allows for efficient set-up and modification of program parameters, with an optional input/output (I/O) staging to optimize production flow. Finally, it offers quick changeover between jobs and a wide variety of material handling and robot control options, with the ability to integrate with third-party process control systems. In summary, ASYMTEK X 1020 is a powerful and user-friendly complete PC board assembly and manufacturing asset. Its modular design allows for easy maintenance and reconfiguration to meet changing production requirements. It also offers intuitive graphics interface and user-friendly software tools, predictive analytics, integrated pressurized liquid dispenser technology, and quick changeover between jobs. It combines high reliability, speed and precision with yield, cycle time and model flow optimization capabilities. It is the ideal choice for high-volume production operations.

There are no reviews yet