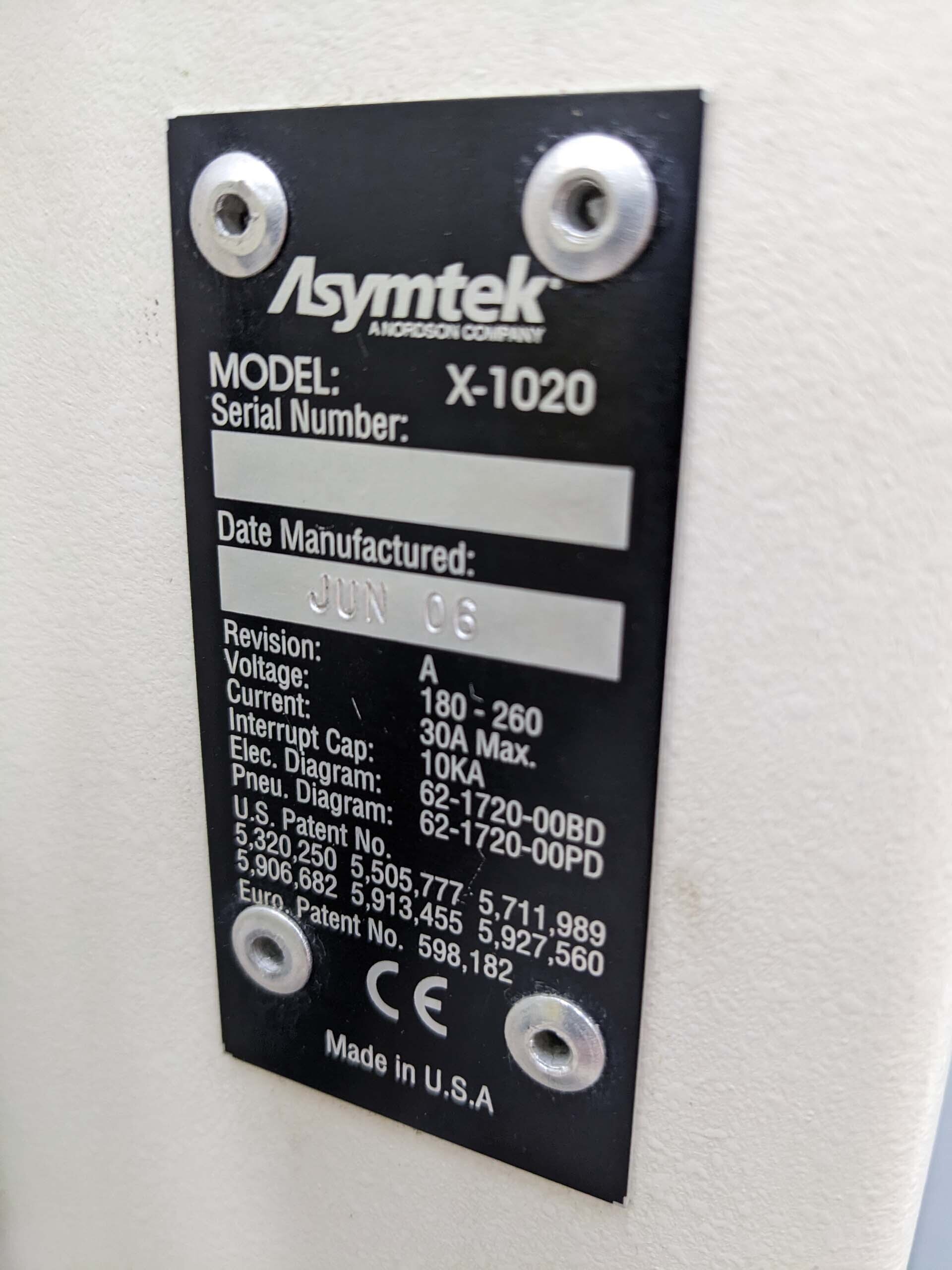

Used ASYMTEK X-1020 #9219497 for sale

URL successfully copied!

Tap to zoom

ASYMTEK X-1020 is a PC board assembly and manufacturing equipment that is designed for high-end production and assembly processes. This system is recognized throughout industry for its technically advanced features, delivering quality performance, productivity, and increases in overall control. ASYMTEK X1020 is a multi-faceted unit that is ideal for large scale production. It has integrated double-sided printing, component placement, reflow soldering, 3D solder paste inspection, and advanced quality assurance technology. It offers precise control over the entire board production process and can be used for a wide variety of component configurations and sizes. X 1020 machine features precision placement technology, allowing for precision placement of components such as BGAs, QFNs, and 0201s. This technology is especially helpful for high-density products that would be difficult to assemble with more basic systems. Additionally, the ISO-certified soldering technology ensures repeatable results and improved solder joint quality. The advanced board handling capabilities of X1020 make it an ideal choice for high-volume production. It features an intuitive user interface, a variety of set-up and management tools, and an open architecture that is compatible with industry-standard formats. ASYMTEK X 1020 also supports several industry-standard CAD systems, allowing for easy integration with existing production lines. The tool also features advanced quality assurance technology that is designed to ensure optimal performance. It offers a range of options for process monitoring and control, including real-time process data collection and statistical process control (SPC) analysis. This advanced data monitoring asset provides feedback on production processes, allowing for faster corrective action if necessary. X-1020 is a reliable and flexible production model for pc board assembly and manufacturing. Its technically advanced features make it an ideal solution for high-volume production, offering optimal performance, improved product quality, and backward compatibility with existing software systems. It is the perfect choice for high-end production and assembly processes.

There are no reviews yet