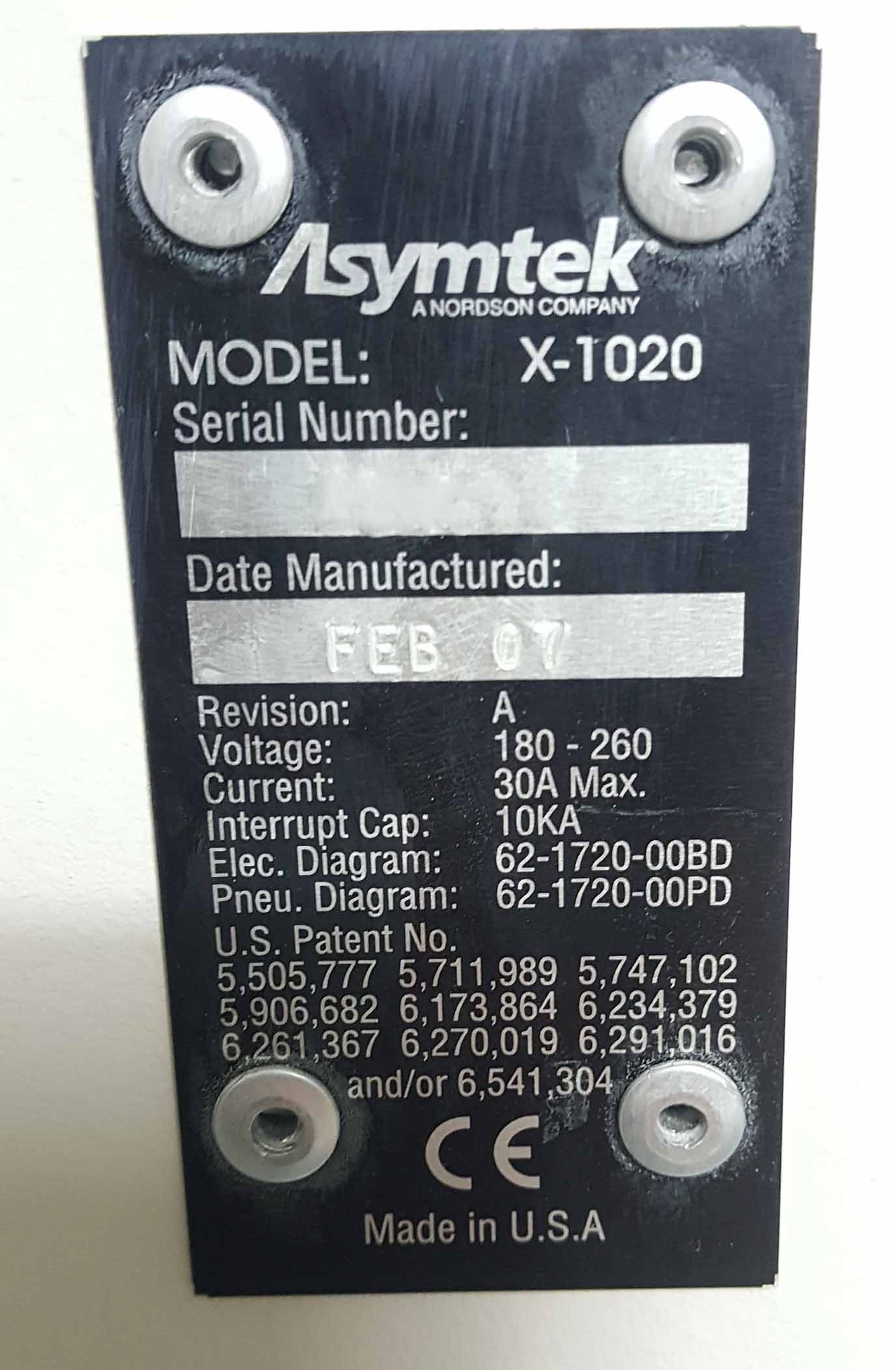

Used ASYMTEK X-1020 #9291619 for sale

URL successfully copied!

Tap to zoom

ASYMTEK X-1020 is a PC board assembly and manufacturing equipment that is designed to make complex assembly tasks easier. It offers a number of features to improve production reliability and efficiency, and is designed to accommodate both small and large-scale projects. ASYMTEK X1020 offers c and usage of automated processes, with a wide array of components that can be used. It uses a combination of vision systems, process control, and inspection technologies to ensure that all components function correctly and are correctly placed on the board. For maximum accuracy, the system includes automatic tooling that eliminates manual labor and removes the need for parts to be reworked or removed. Additionally, the unit features vacuum pickup technology for components placement, as well as for the alignment of parts in the machine. To help manage the PC board assembly, X 1020 features an intuitive software interface that updates various parameters and keeps a record of the current status of the project. This helps facilitate communication between the operator and the machine and allows quick changes if necessary. The software can also be used to manage reports, charts, and other production information. ASYMTEK X 1020 is designed to help manage and supervise all phases of the production process. It allows for inventory tracking and the generation of information such as engineering change orders and pass/fail data for each board being produced. Additionally, the tool can generate ESD (electrostatic discharge) data and offer an audit trail to prove that all guidelines have been met. X-1020 is designed with a series of built-in safety measures. It uses a closed loop control asset to ensure maximum quality and production reliability. Additionally, there is an emergency stop feature that allows for an immediate stop of operations if necessary. The model also uses redundant hardware as an additional safeguard in case of emergency. X1020 is built with a short cycle time and offers quick setup times, to help minimize downtime and maximize productivity. It is designed to handle multiple boards at once through its high-speed processing capabilities and can produce up to 1000 boards per hour. ASYMTEK X-1020 is designed to help automate the PC board assembly process and offers features to maximize quality and productivity, along with built-in safety measures to ensure the highest standards for the best possible results.

There are no reviews yet