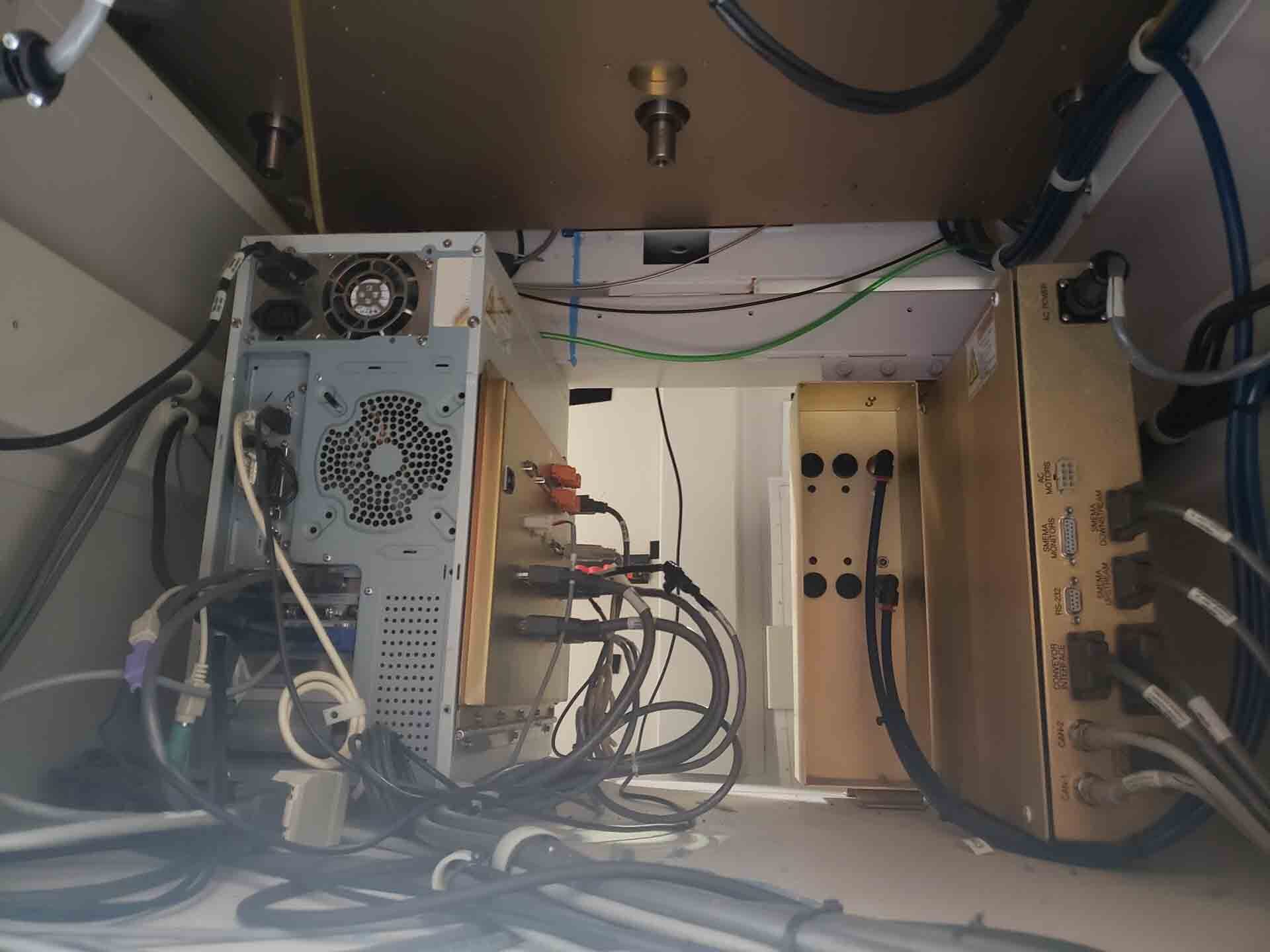

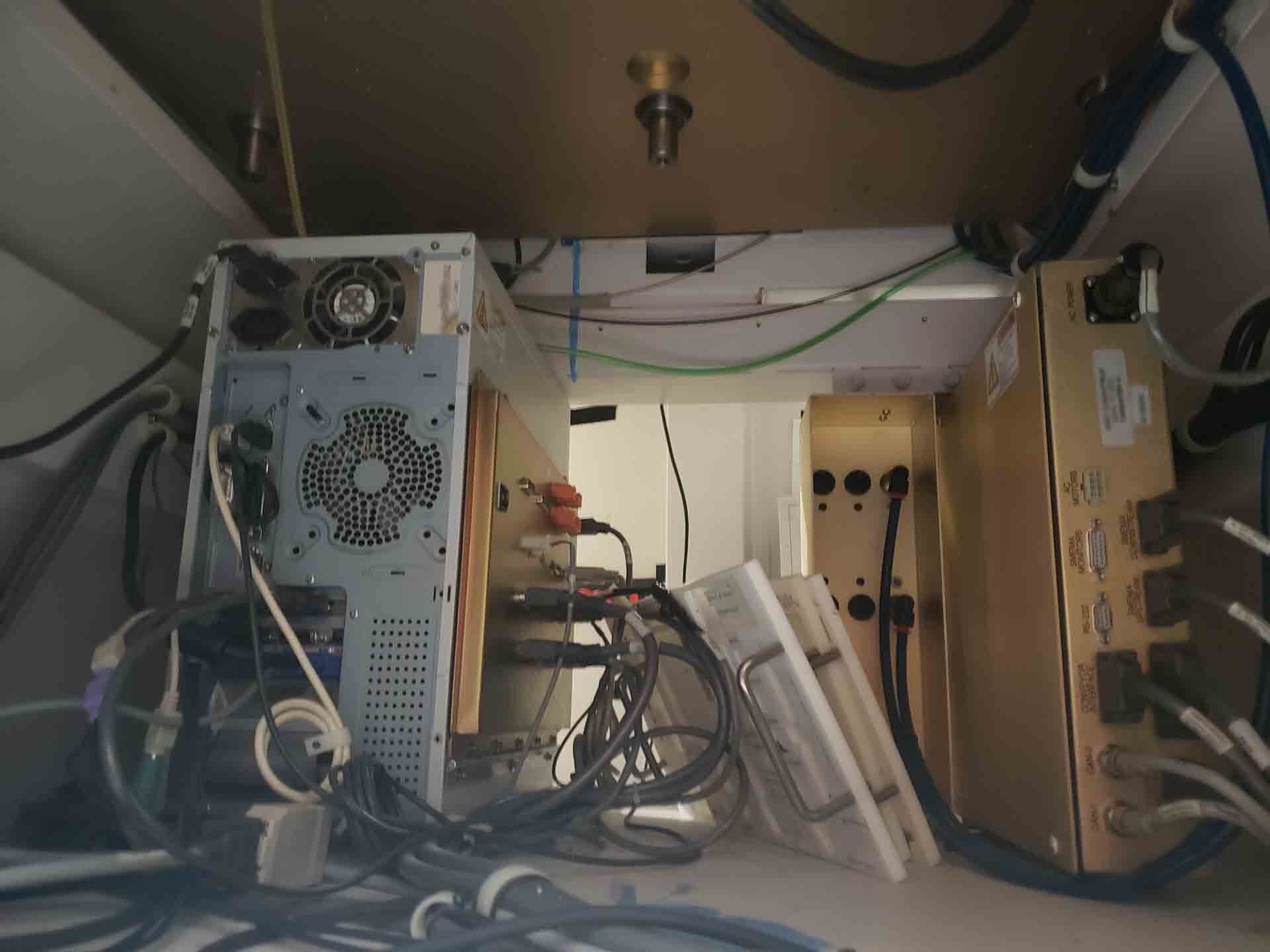

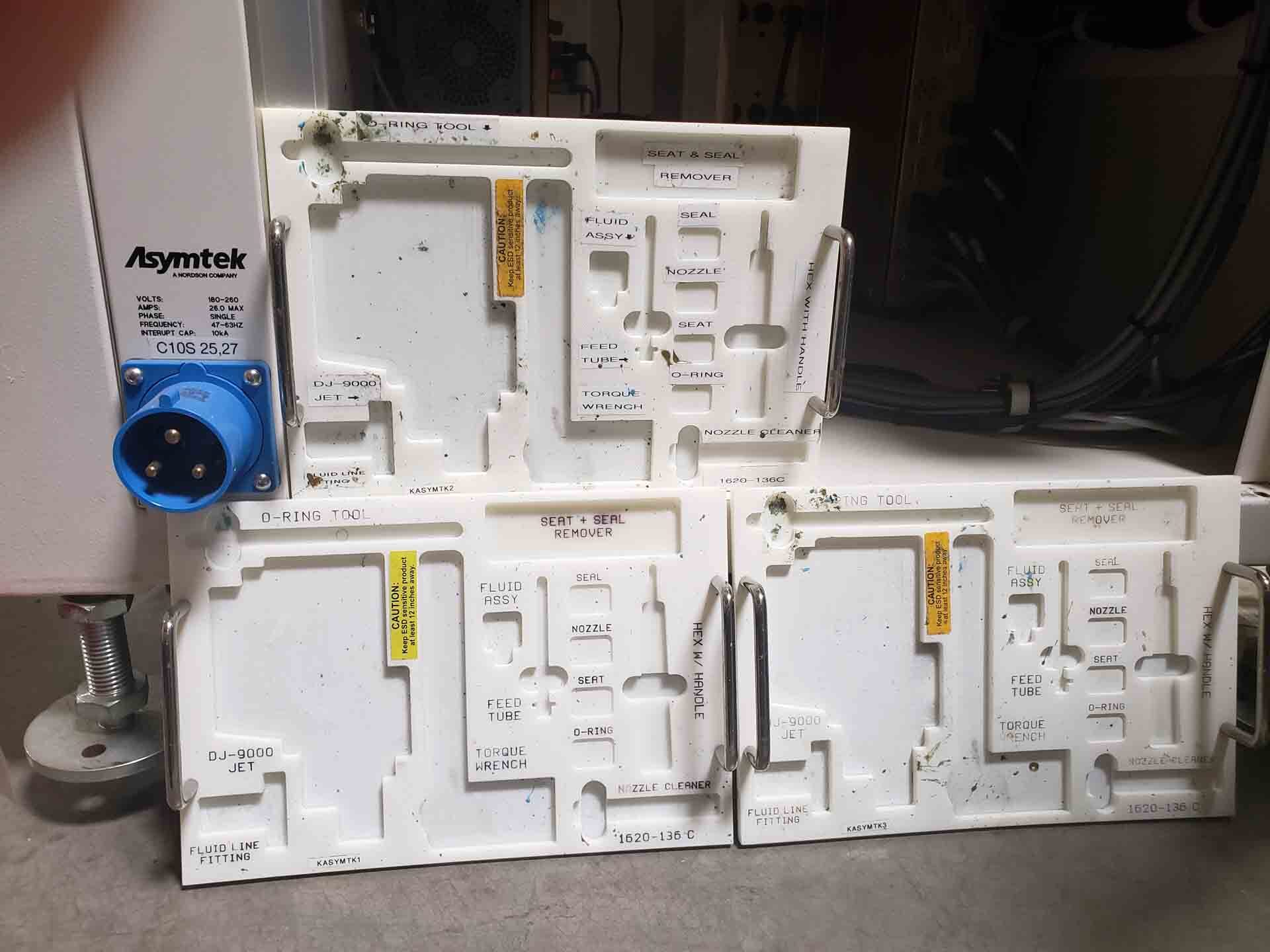

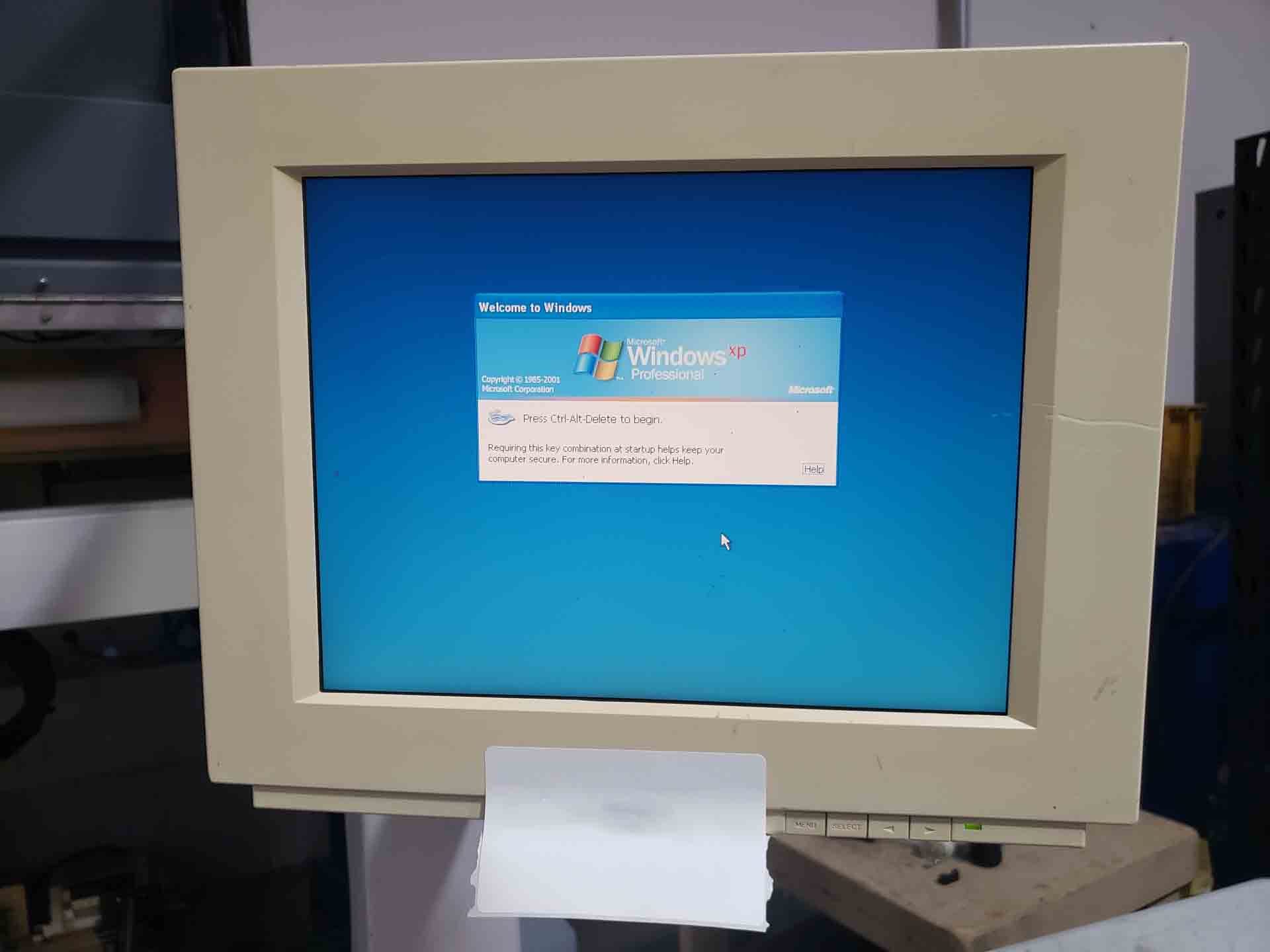

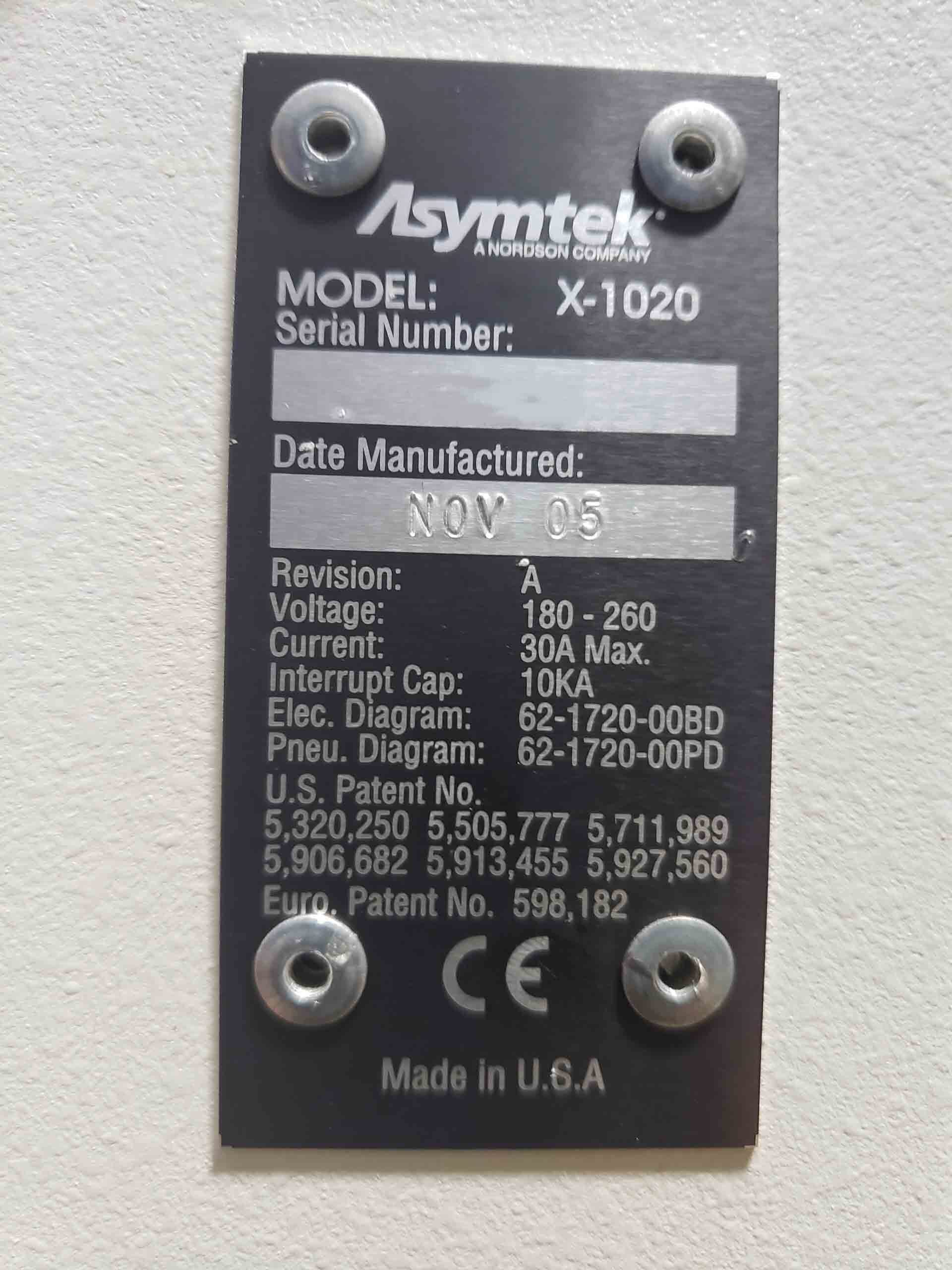

Used ASYMTEK X-1020 #9396085 for sale

URL successfully copied!

Tap to zoom

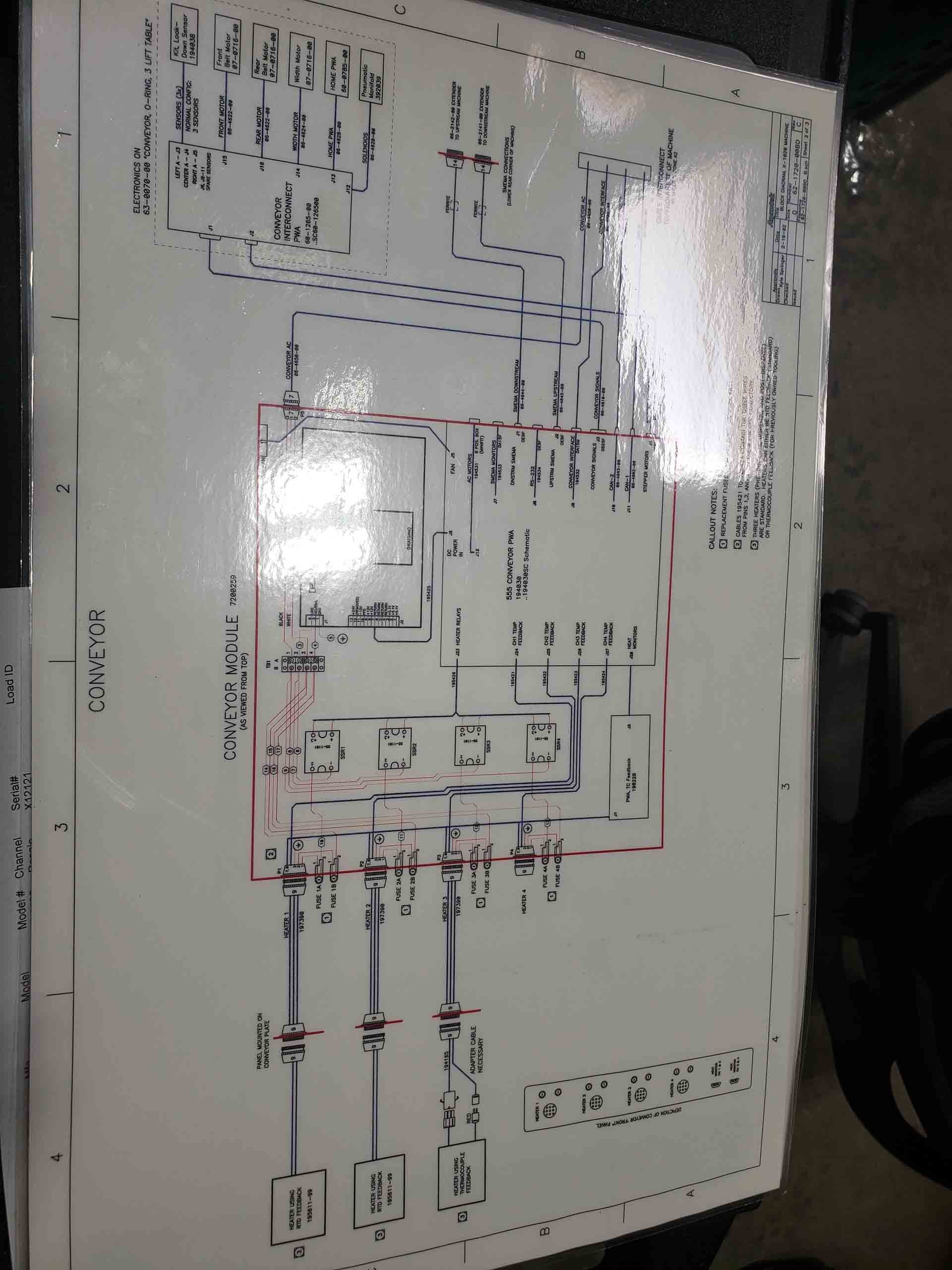

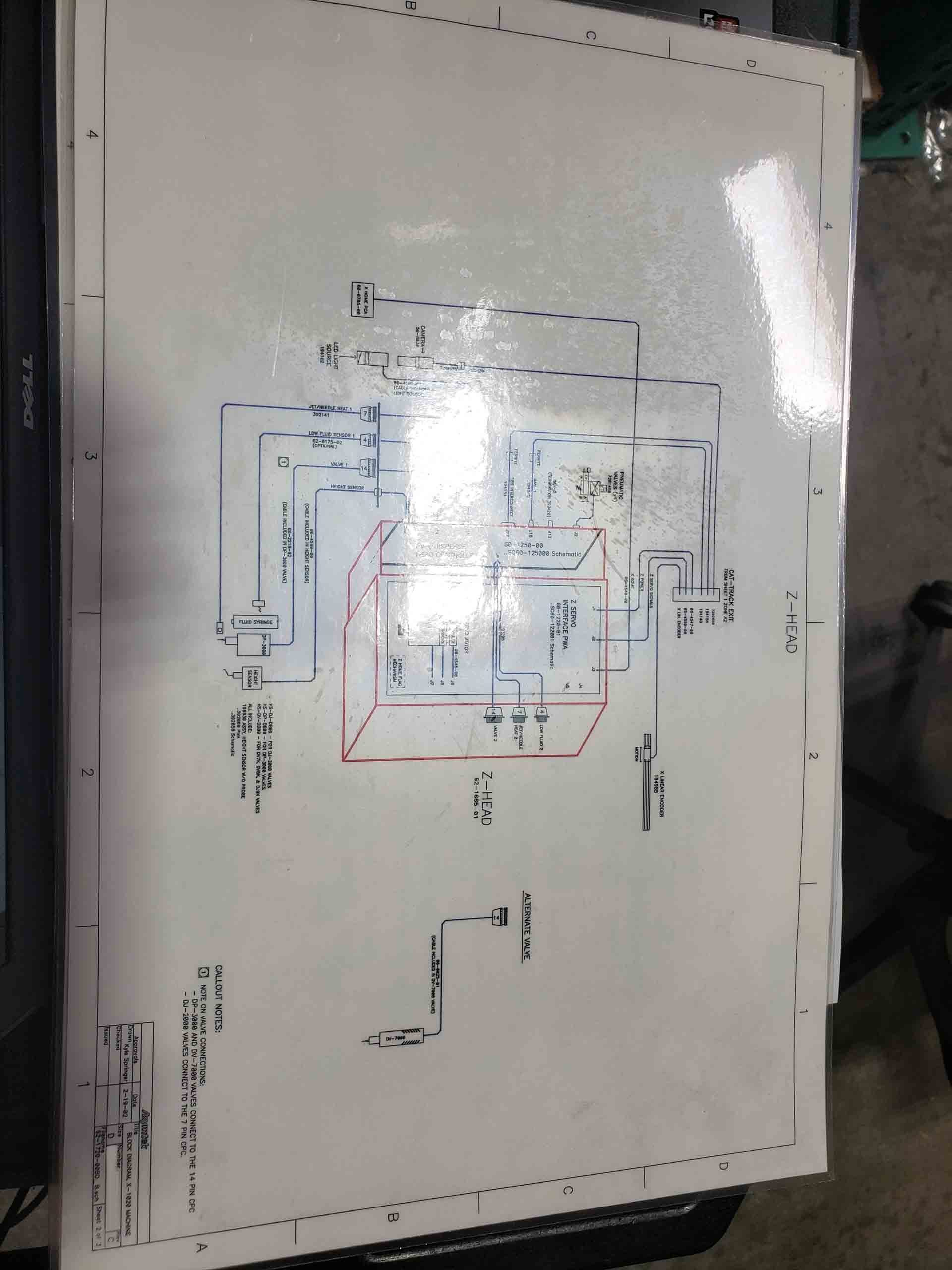

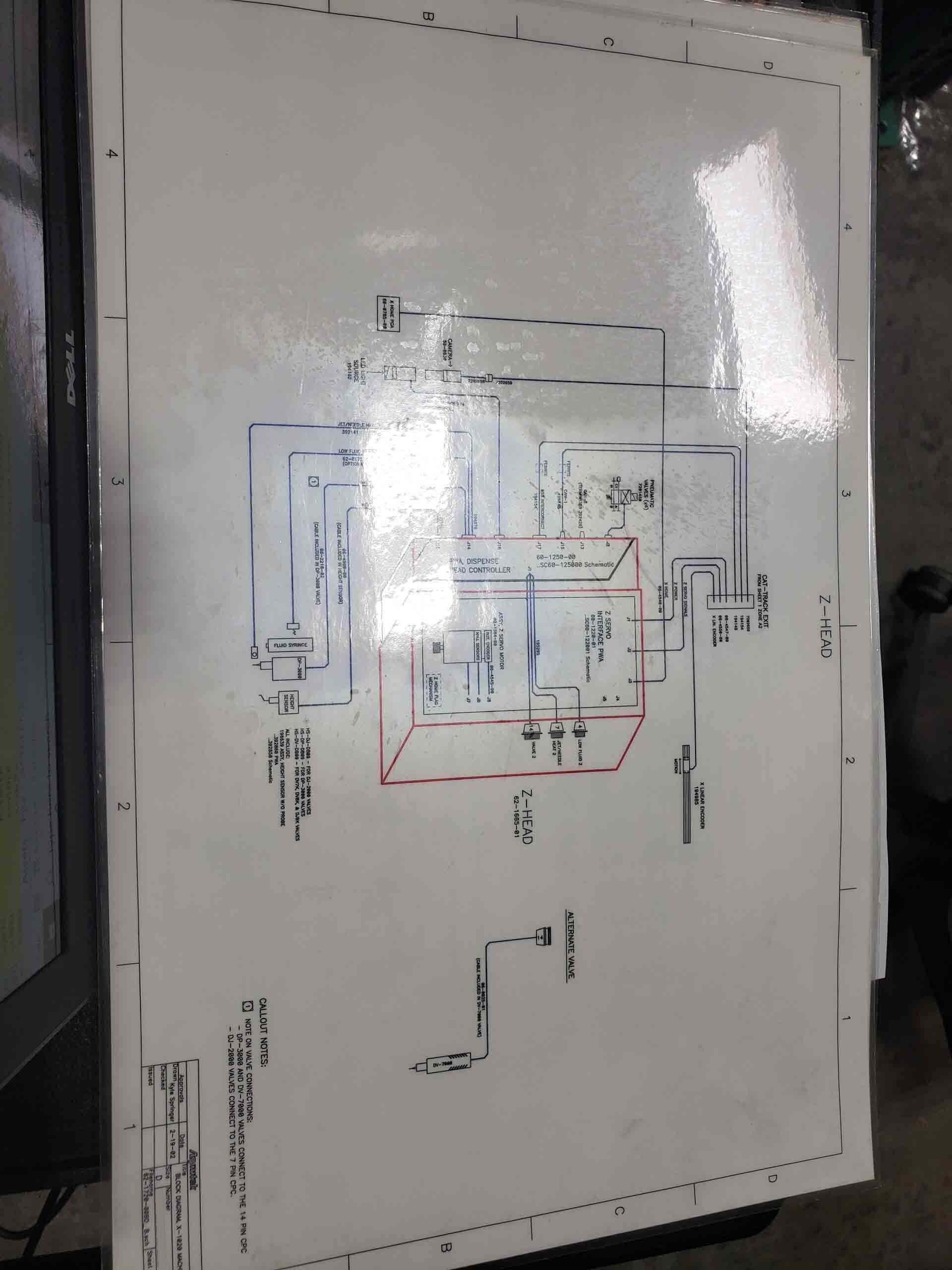

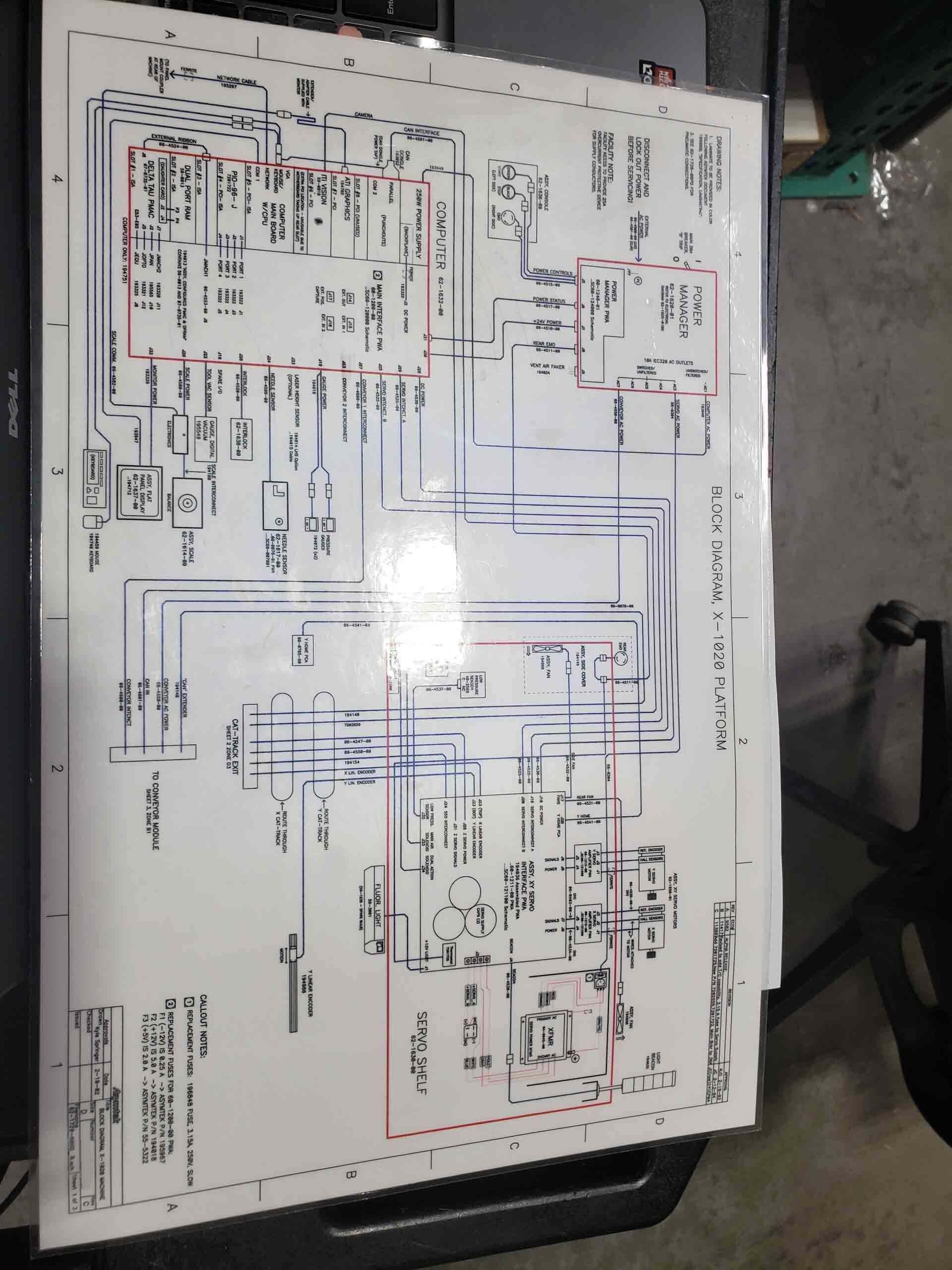

ASYMTEK X-1020 is a fully automated, single-board manufacturing and assembly equipment designed for high speed production of pc board assemblies. It is ideal for applications such as placing SMT components onto PCBs, reflow soldering, and inspection. ASYMTEK X1020's features an integrated, XY placement system and a variety of nozzles for superior accuracy. The machine is built with a lightweight frame, allowing for maximum flexibility and easy installation into any production environment. The unit is equipped with an intuitive graphical user interface, providing optimized menu functions and reduced set-up times for maximum throughput. X 1020's high speed placement machine is accurate and reliable, boasting a resolution of 0.0025mm. It also features a pusher detection capability so that any partial component pick-ups can be detected and the relative position of the component can be instantly corrected in real-time. The placement tool also has an integrated vision asset to detect close components and irregularly shaped parts. The soldering model in X1020 is designed to maximize performance under a variety of production conditions. It uses an infrared heating equipment with quartz radiators, giving it an ability to reach the maximum temperature within 1.6 seconds for maximum throughput without sacrificing the quality of the soldering process. ASYMTEK X 1020 also features a multi-jet X-Y conveyor cleaning system, designed to stabilize surface temperature and to keep the components clean before reflow soldering. Finally, X-1020 is equipped with a powerful 3D AOI (Automated Optical Inspection) module. This module is capable of quickly detecting any soldering defects on the pc board assembly's surface, and offers auto-teaching and 3D inspection algorithms to support a wide range of inspections. In conclusion, ASYMTEK X-1020 single-board manufacturing and assembly unit is an ideal choice for pc board assembly production, offering high speed placement, reliable soldering, and thorough 3D AOI inspections. It is easy to install into any production environment, and its graphical user interface ensures optimized menu functions and reduced set-up times for maximum productivity.

There are no reviews yet