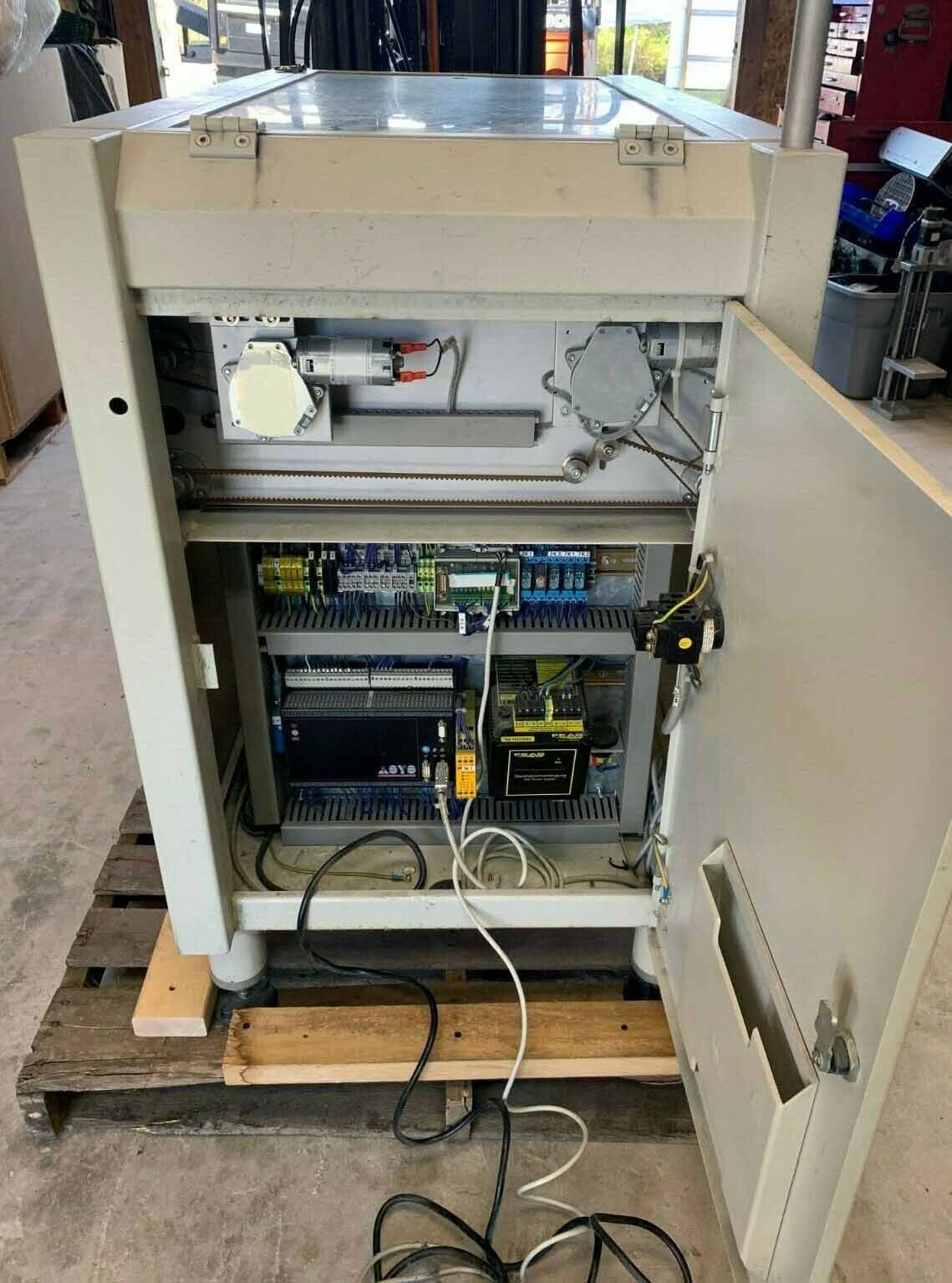

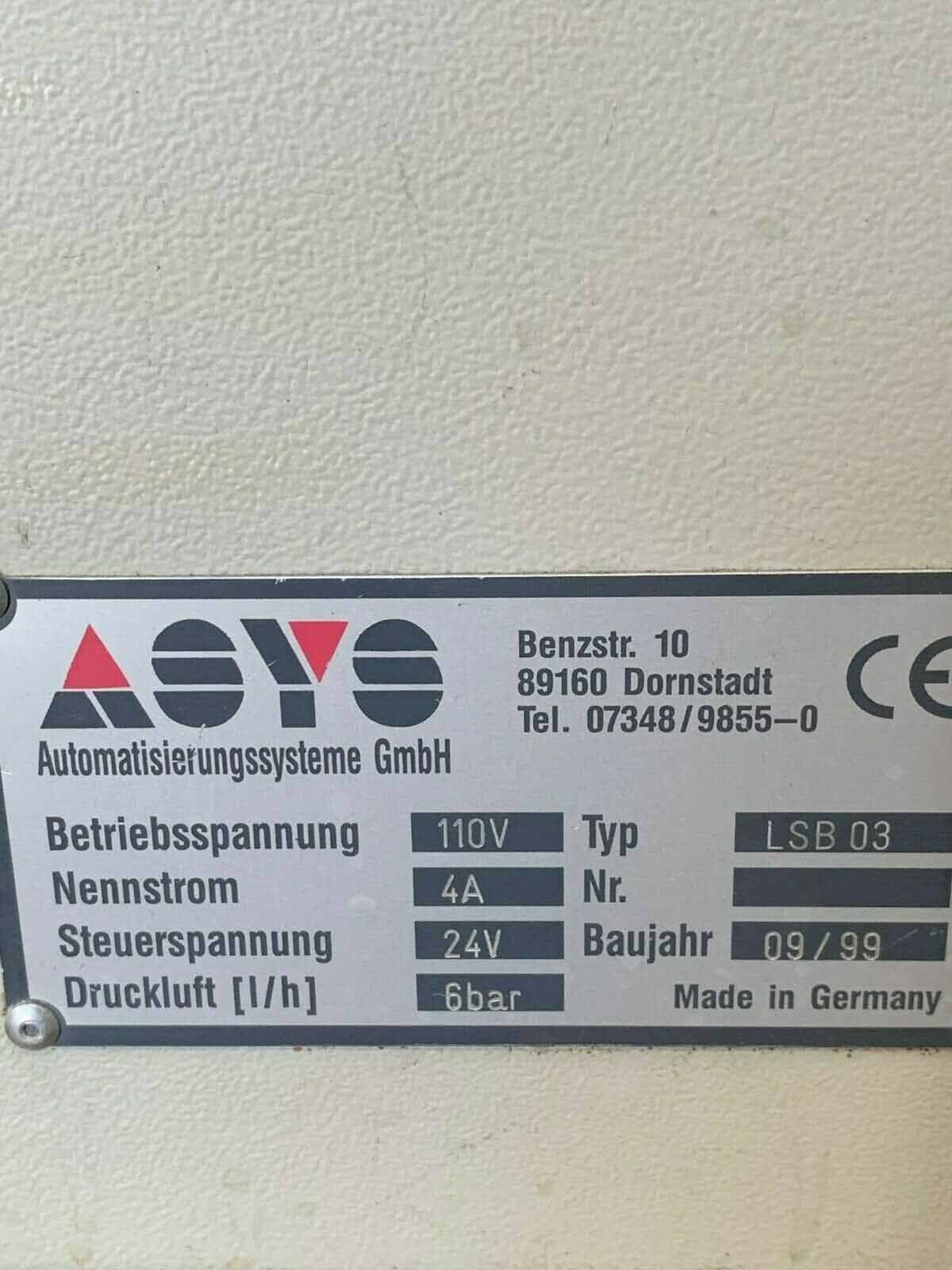

Used ASYS LSB03 #293609374 for sale

URL successfully copied!

Tap to zoom

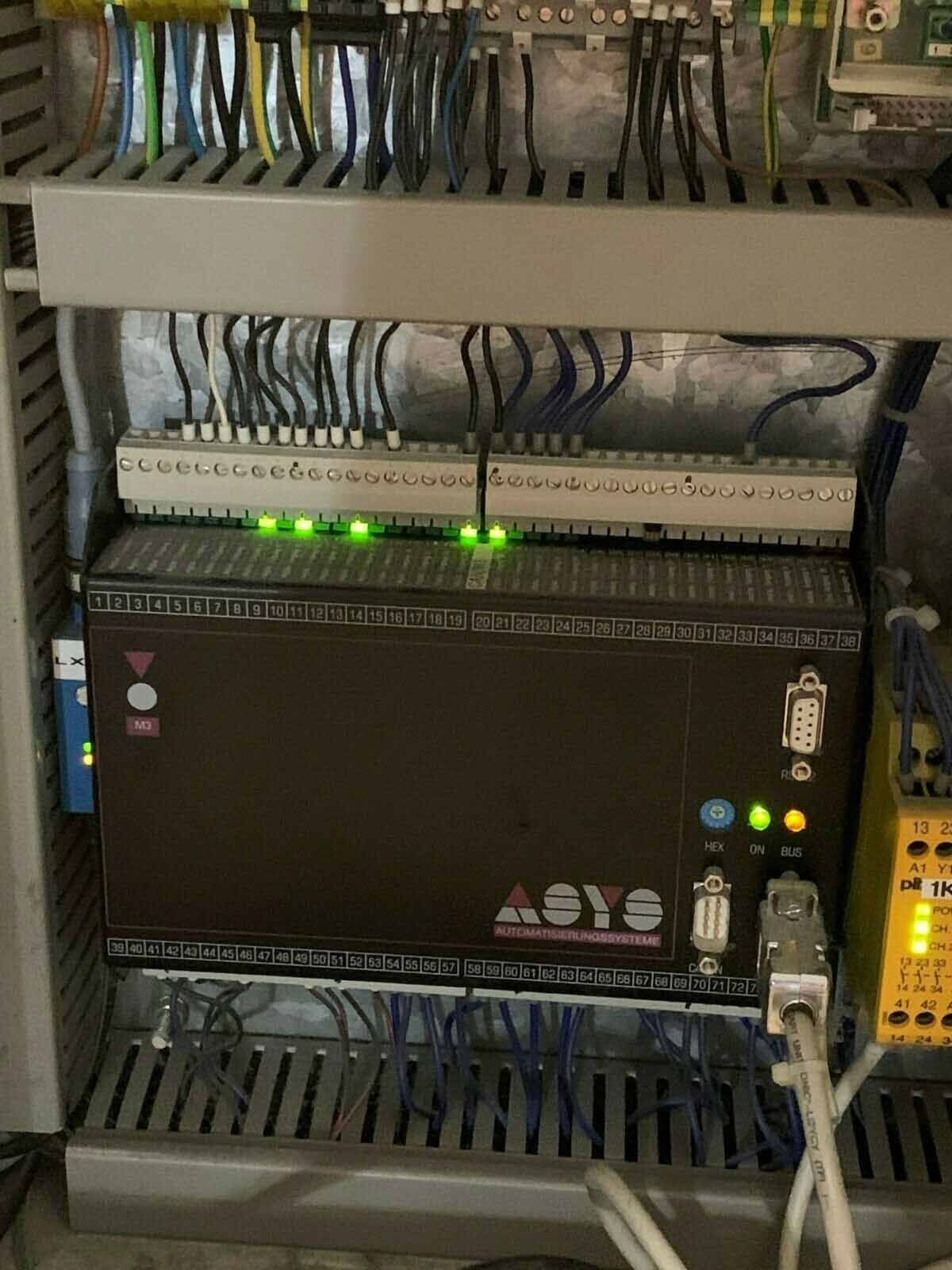

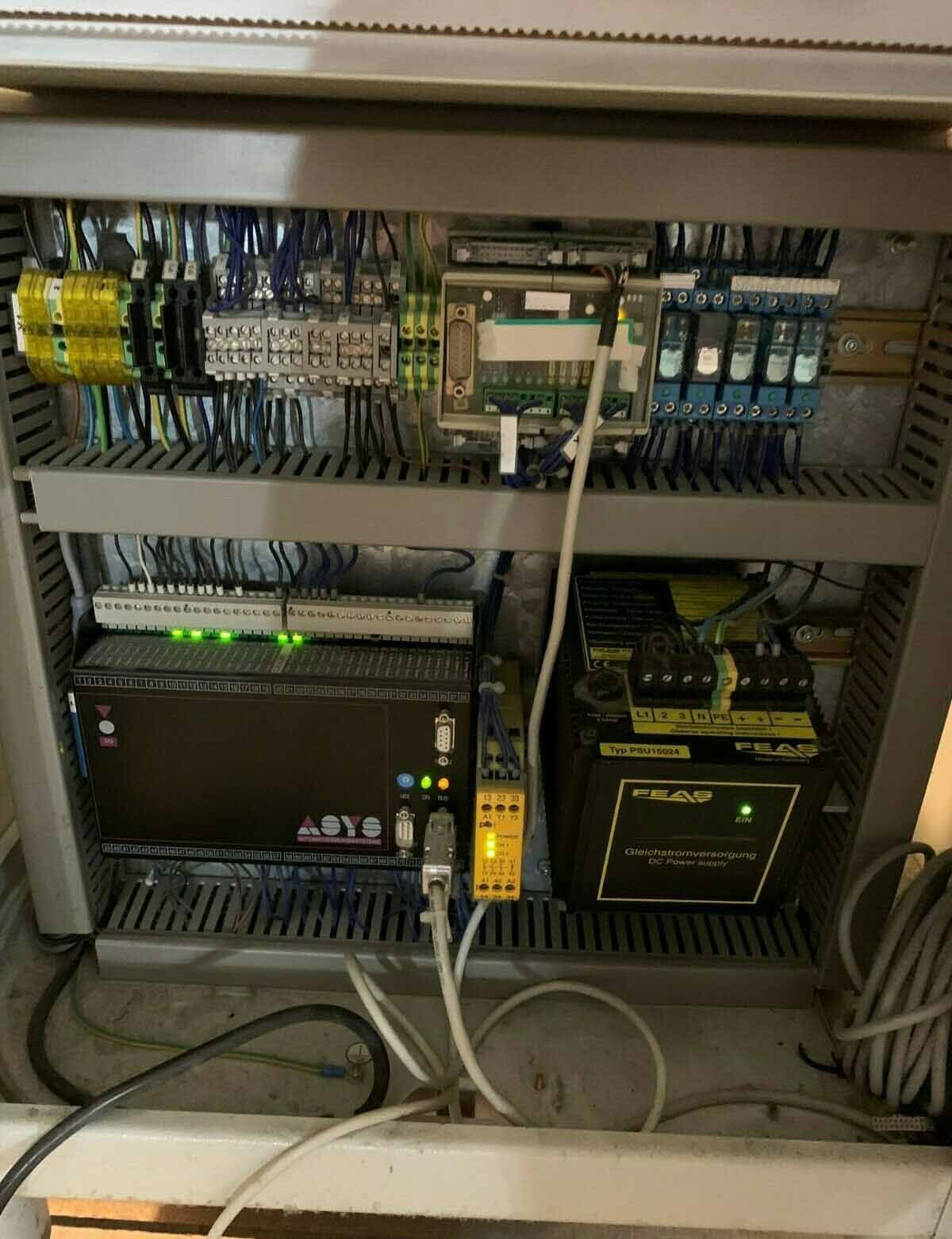

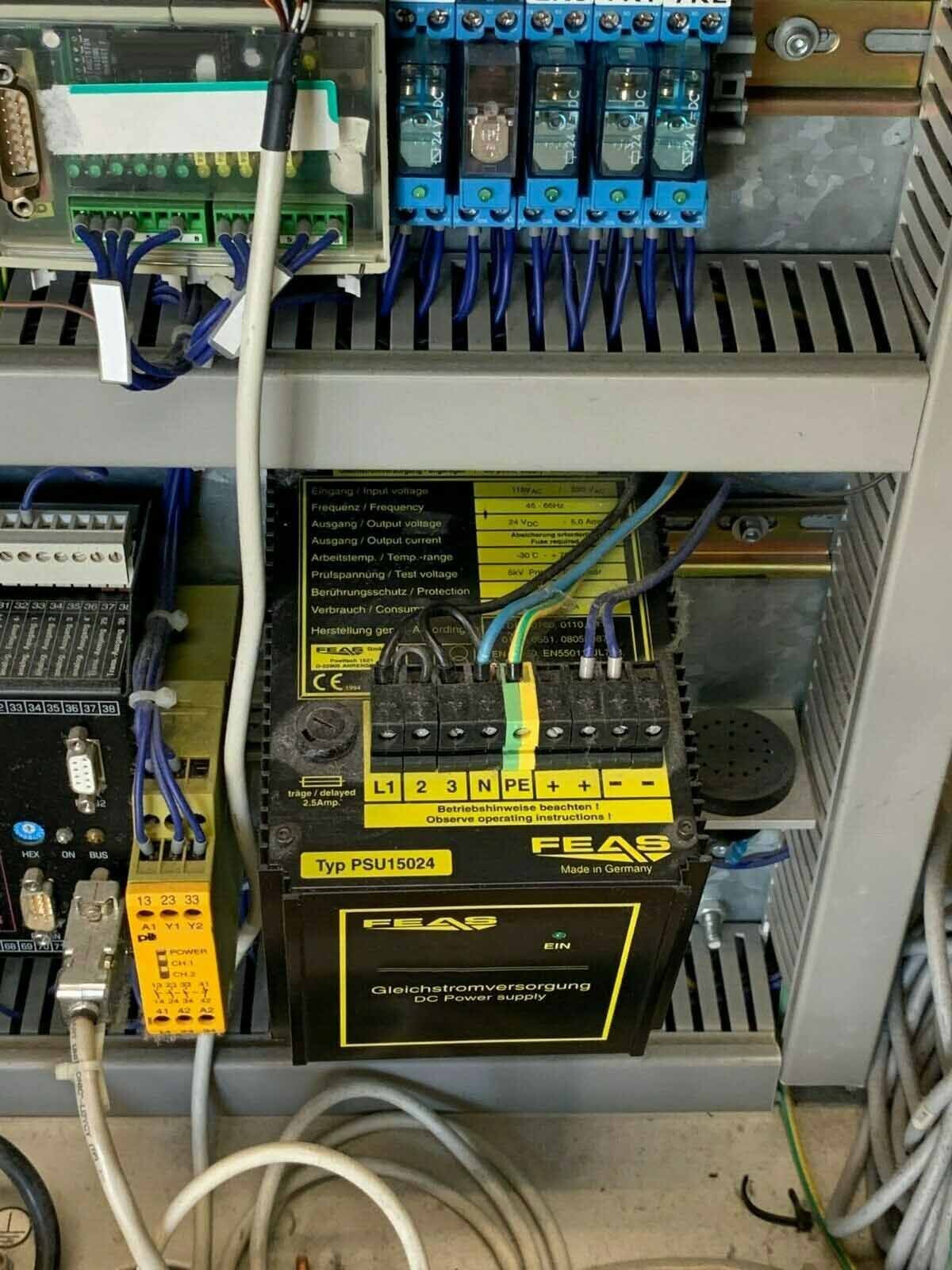

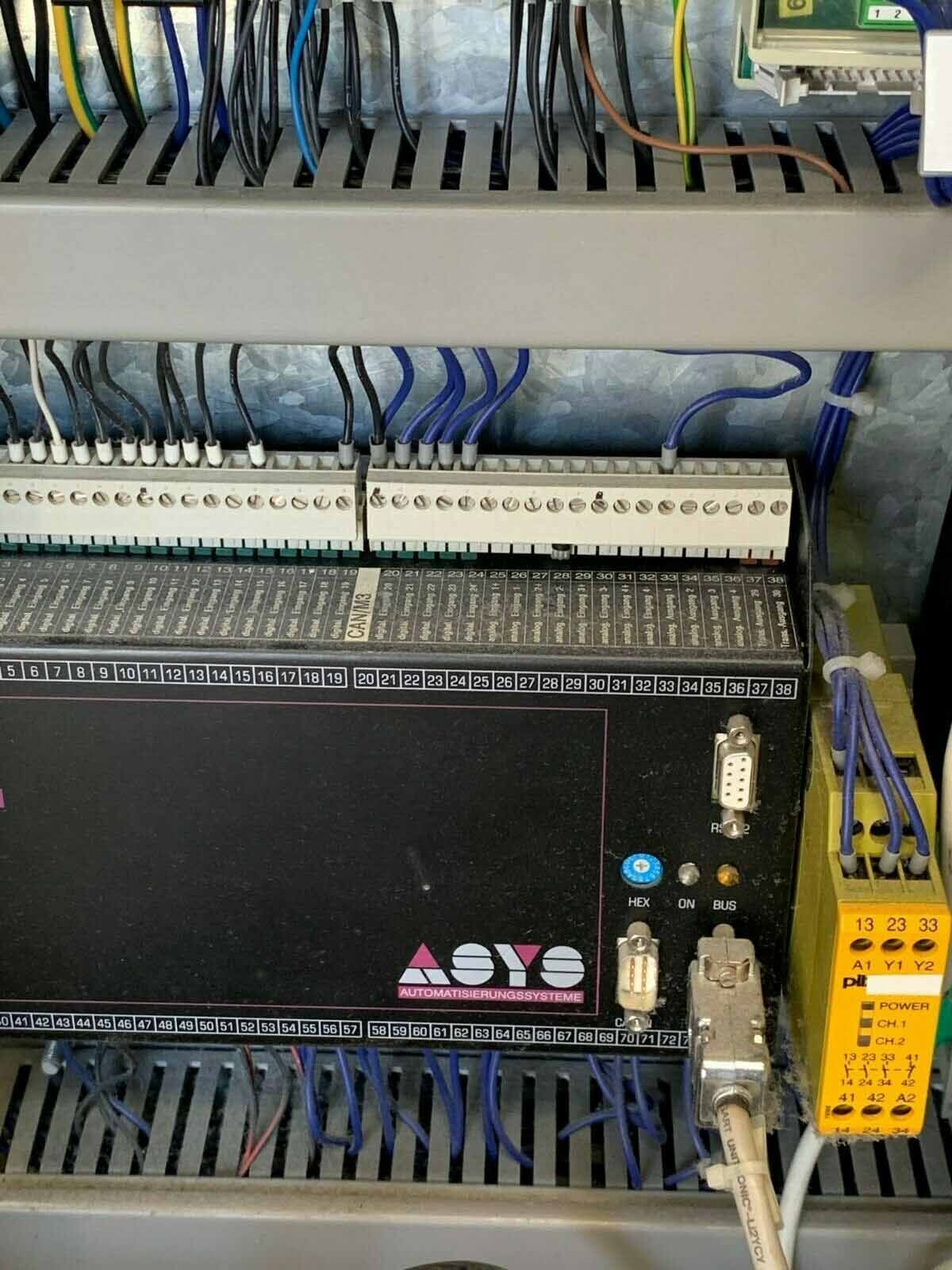

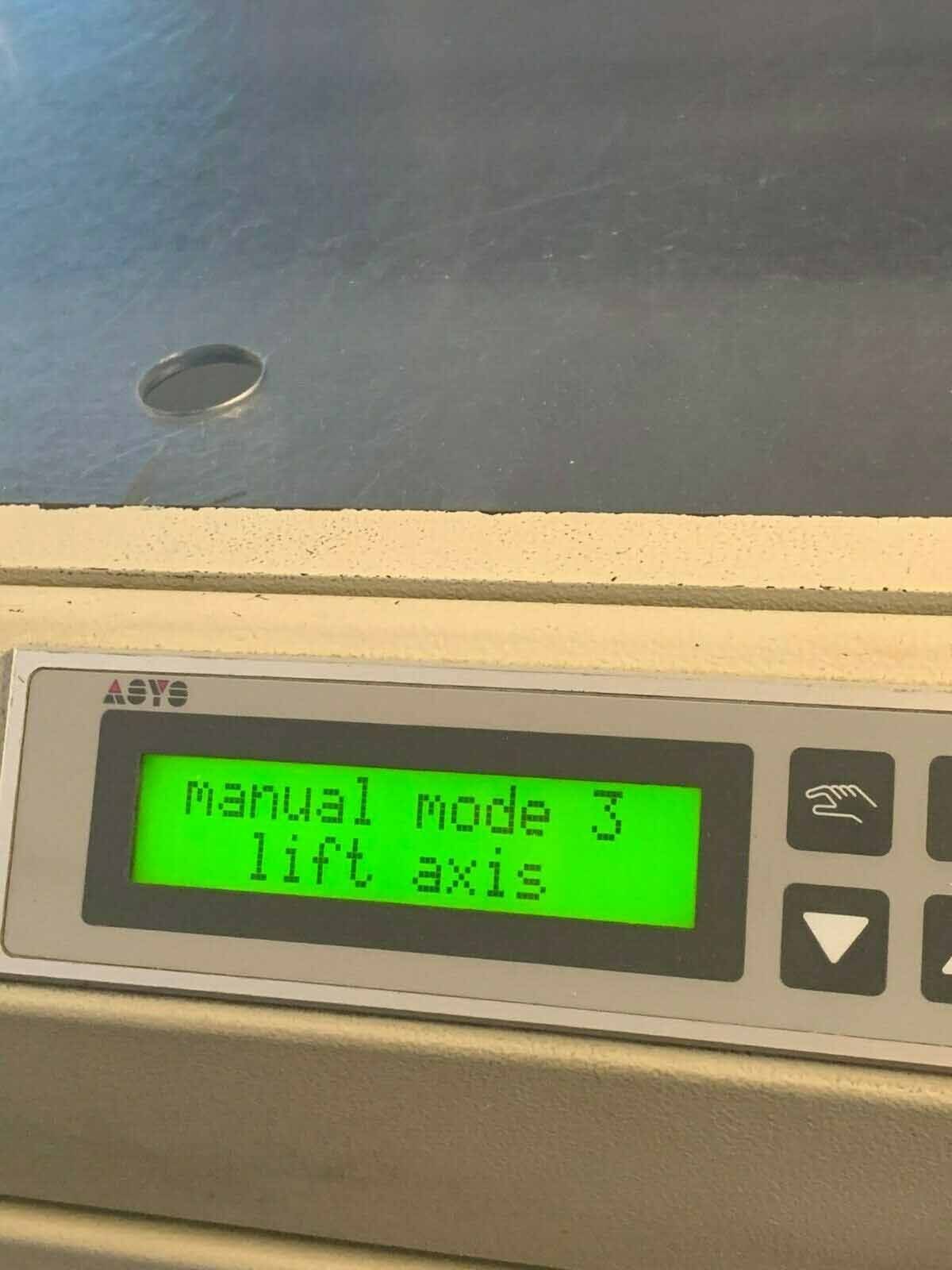

ASYS LSB03 is a pc board assembly and manufacturing equipment designed to streamline all stages of machine-based production. It is capable of providing precision and accuracy through the application of software and hardware technology. The system incorporates advanced industrial automation functionality to offer cost-effective production processes. On the hardware side, the unit includes a robust machine architecture that includes a main controller, several Gantry stations, a component identification tool and a versatile motion control unit. The main controller is responsible for the integration of the asset and its components, as well as controlling the physical production parameters. The Gantry stations allow the automated pick and place of components. The component identification model is used to identify the components to be placed. Lastly, the motion control unit is responsible for producing the exact number of parts required for a given order. On the software side, ASYS LSB 03 equipment is equipped with several tools that enable operators to produce top-notch quality products. These tools include Gerber Manufacturing System (GMS), a powerful production planning software. GMS allows operators to quickly create, modify, and test component designs. Along with GMS, the unit also features e-panel, an electric screen control machine for inputting and managing component placement data on the assembly panel. LSB03 also possesses a wide range of technologically advanced features. This includes an intelligent vision checking tool that uses cameras to inspect components during production. Advanced tooling provides the necessary component registration accuracy while its robotic handling asset ensures precise orientations and placements of components. Furthermore, the model is capable of handling multiple types of work pieces with the interchangeable attachment systems. Overall, LSB 03 is an ideal choice for those looking for a reliable, cost-effective and automated pc board assembly and manufacturing equipment. With its advanced features and powerful production planning tools, the system can deliver consistent, high-quality results that meet the exact specifications of the customer.

There are no reviews yet