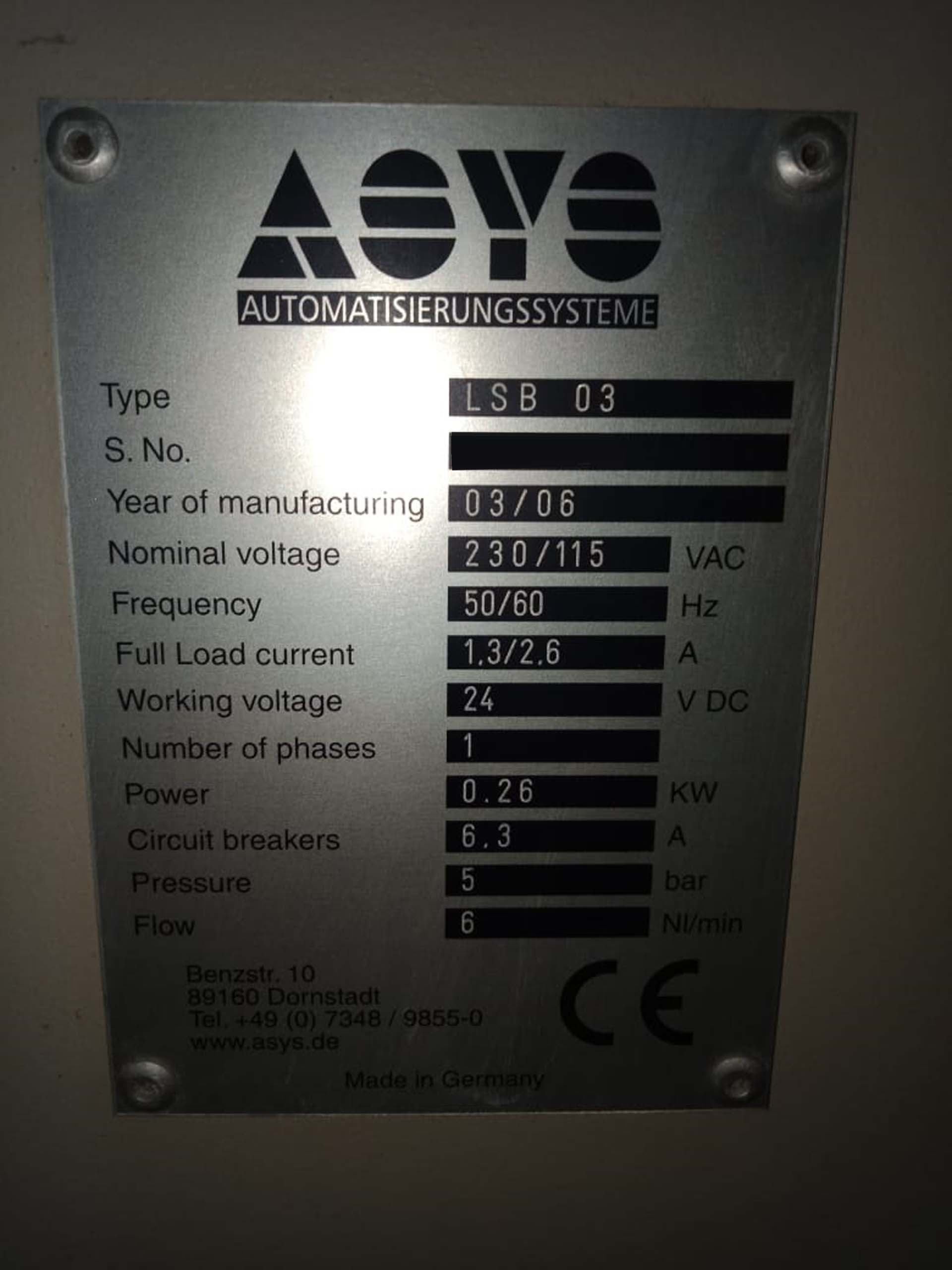

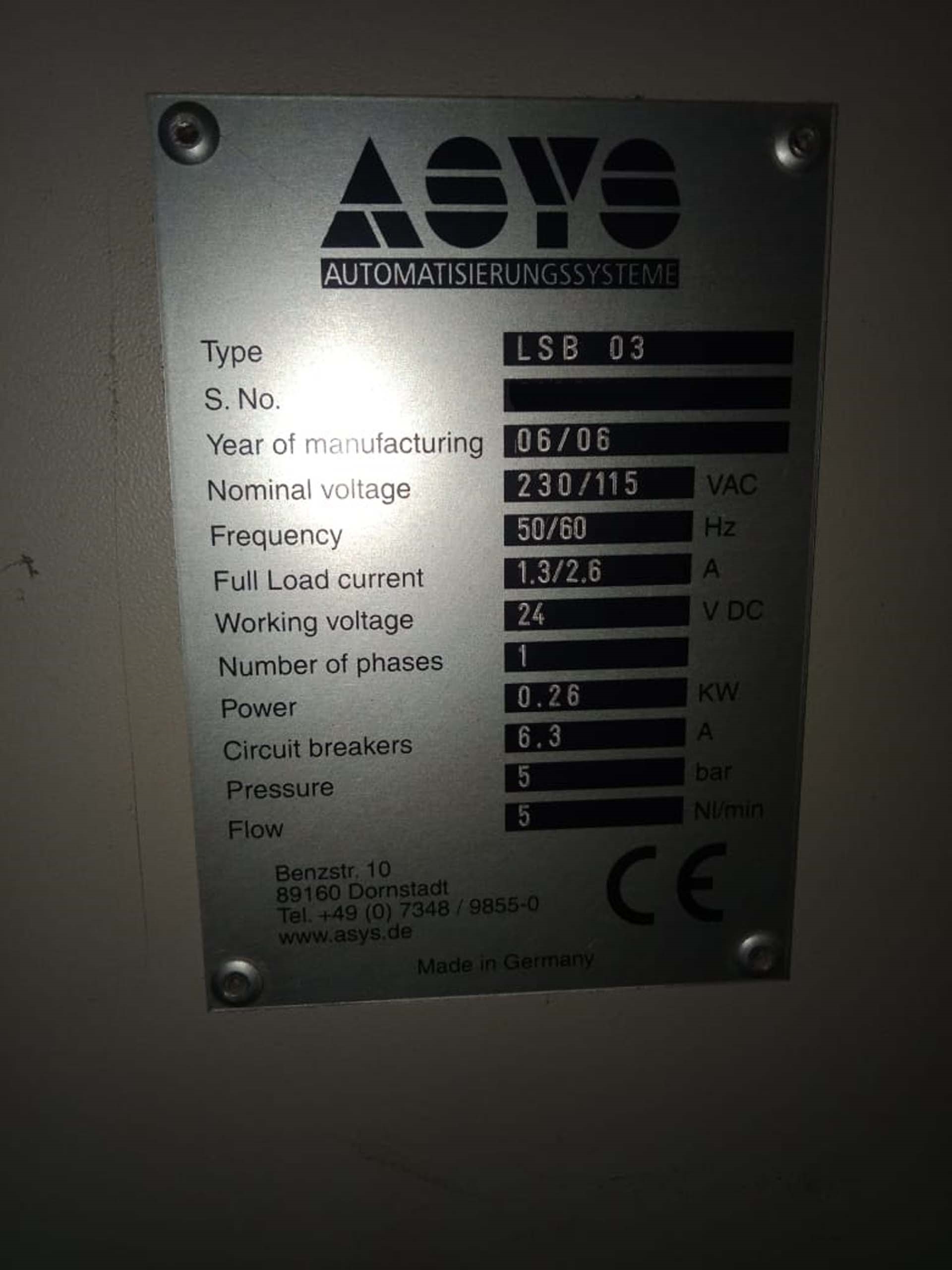

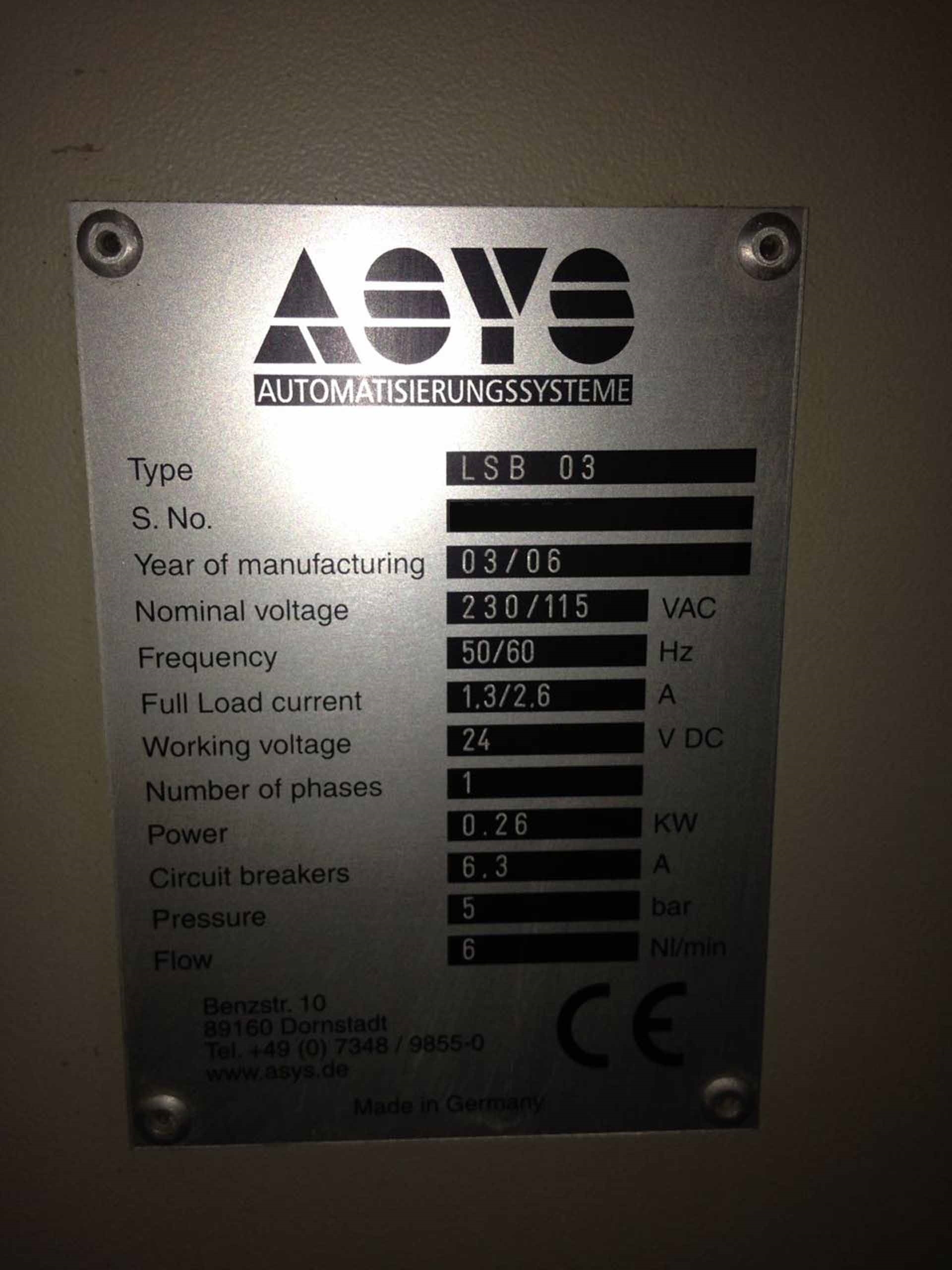

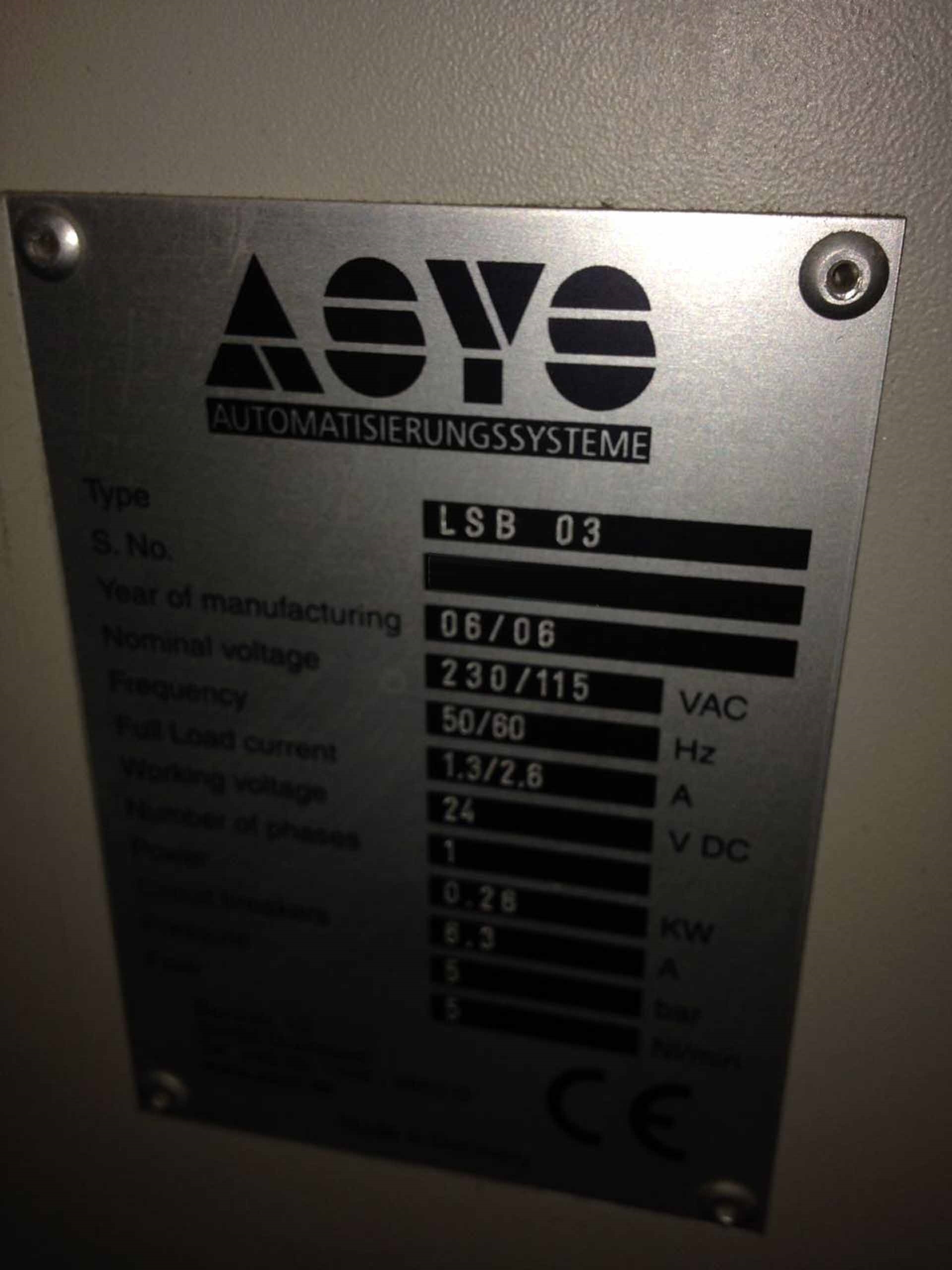

Used ASYS LSB03 #9221655 for sale

URL successfully copied!

Tap to zoom

ASYS LSB03 is a printed circuit board (PCB) assembly and manufacturing equipment developed by ASYS Group. It is designed for high-precision electronics manufacturing processes such as soldering, polishing, and inspection. The system is made up of three main components, namely: A base unit with an integrated conveyor unit for transporting and positioning boards appropriately in the manufacturing process. A robotic arm with integrated measurement and motion controls that allow for precisely timed and highly reliable soldering and polishing of PCBs. A control unit for managing and monitoring the entire assembly and manufacturing process remotely. The base unit is primarily responsible for securely transporting the PCBs from one area of the machine to another. This is accomplished by integrating a belt-driven conveyor that can move the boards at varying speeds depending on the task at hand. The conveyor machine also allows for precise positioning of the board for soldering and polishing operations, making sure that each operation is completed accurately and efficiently. The robotic arm is the second main component of the tool and is responsible for performing the actual soldering and polishing operations. The arm consists of a specialized nozzle and a camera which are connected to a motion control asset. This allows the robot arm to accurately identify and solder the components to the board with no errors. Also, the camera allows for accurate inspection during the manufacturing process to ensure that all soldered components are properly and securely placed. The control unit is the brain of the model and is used to manage all the different assembly and manufacturing functions. It consists of a computer with specific software packages that allow for complete control and monitoring of the production process. The software can be used to manage the speed of the conveyor, set working parameters for the robot arm, specify the exact components to be soldered, provide visual indicators of current manufacturing statuses, and provide log files for tracking errors. Overall, ASYS LSB 03 integrated equipment is designed to make the assembly and manufacturing of PCBs faster, more accurate, and more reliable. With its highly automated processes, the system is ideal for mass production of high-precision electronics. By taking advantage of the automated conveyor, robotic arm, and control unit, users can rest assured that their PCBs are assembled and manufactured to exact specifications.

There are no reviews yet