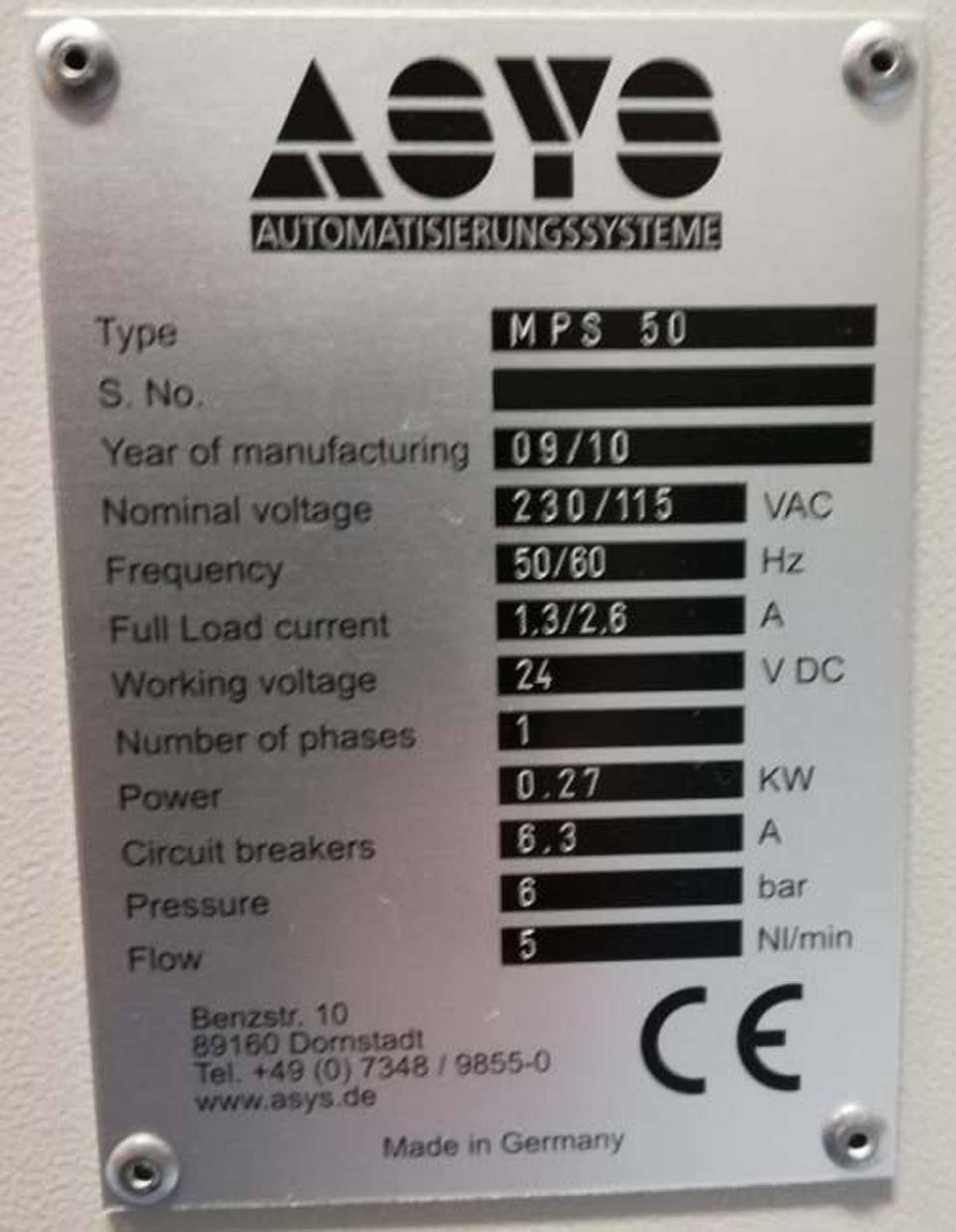

Used ASYS MPS 50 #9240548 for sale

URL successfully copied!

Tap to zoom

ASYS MPS 50 is a complete automated PC board assembly and manufacturing equipment, designed to provide cost-effective and efficient manufacturing industry performance. This system provides features such as integrated production lines, high-end quality, and short processing times for components. It is an advanced automated production unit designed to facilitate the production of high-quality and cost-effective PC boards. The machine is capable of processing and assembling all types of components, such as surface mount devices (SMD's), connectors, switches, chokes, and so on. The tool features an integrated pick-and-place assembly that can handle up to 50 boards per hour, while providing excellent repeatability and accuracy. The asset is powered by two motors, intelligent motion control, and redundant position sensors, enabling precise integration and alignment of components. MPS 50 also features a fully automated test and inspection model, which can check the integrity of the components and their connections. Additionally, the equipment features an integrated load board that allows for testing of multiple boards simultaneously, ensuring quality assurance. The system is also equipped with a modular milling and routing unit that can process a variety of PC boards. This machine is programmable and user-friendly, making the production of quality PC boards easy and cost-effective. Furthermore, the flexible resin dispenser aids in the efficient and cost-effective production of quality PC boards. The tool comes with a built-in controller that is responsible for controlling and pumping the resin, and can be automated to speed up the material flow. Additionally, the automatic handling unit features off-line storage of components for further assembly operations. Finally, ASYS designed ASYS MPS 50 to be highly reliable, making it a long-term investment in the industrial environment. Advanced diagnostics software are included, allowing for rapid troubleshooting, as well as preventive maintenance and flexibility. The asset is also compatible with other systems on the same machine line, making it an excellent and reliable addition to any production facility.

There are no reviews yet