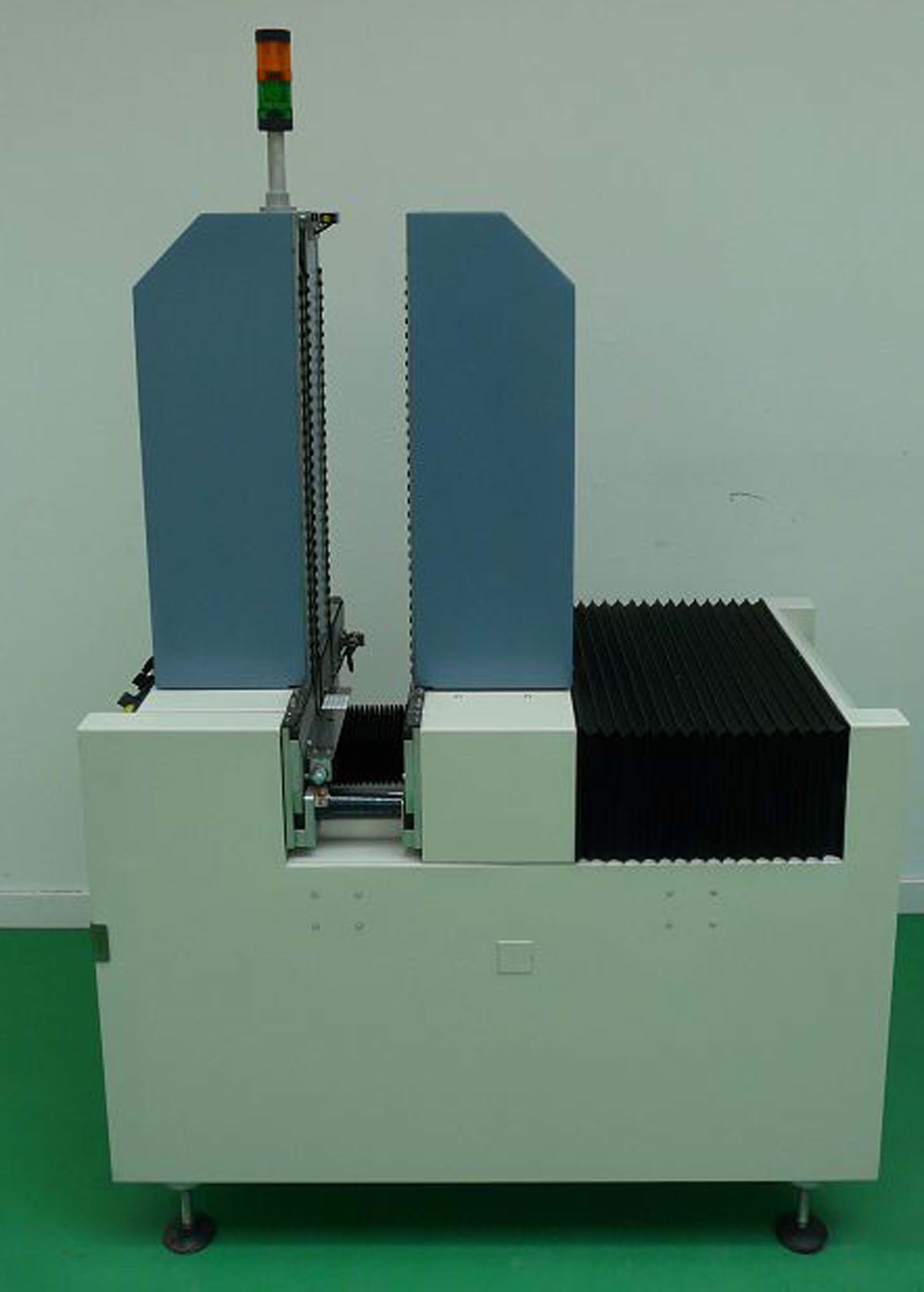

Used ASYS PS 30 #9245046 for sale

URL successfully copied!

Tap to zoom

ID: 9245046

Vintage: 2005

LIFO Buffer

Up to (30) PCBs

Transport direction: Left to right

2005 vintage.

ASYS PS 30 is a pc board assembly and manufacturing equipment designed to meet the needs of small and medium-scale production. The system offers a versatile and reliable platform for circuit testing, repair, and unit integration. It is capable of assembly and testing of all popular surfaces-mount and through-hole components. The Machine offers three mounting position modes: pre-assigned, simultaneous and rolling. With a pre-assigned mode, parts are assigned specific locations and the replacement mechanism moves the boards to pick up each component automatically. The simultaneous mode allows for simultaneous placement of components on the boards. The rolling mode provides the flexibility to place components at different locations on the board in any sequence. PS 30 is a simple one-step tool, consisting of an assembly module and a power supply unit. The assembly module contains all the components needed for the assembly, while the power supply unit provides the necessary power to execute the assembly operations. The asset is equipped with advanced optics to detect component type, size, and placement. These features enable it to accurately detect and place components on the PCBs. The model also has a monitor to observe the status of the equipment and the lines. The system is designed for reliability and efficiency. The high-speed assembly and testing processes allow the production of quality products quickly and without interruption. The PC board assembly and manufacturing process is also supported by a set of integrated tools, such as 3D CAD, AutoCAD, CAM software and a CAM editor. A wide variety of accessories are available that enable the unit to its full capability. The design of the machine is organized into blocks. These include the input/output section, the processor section, the memory section and the control section. Each section is designed to perform a unique task. The input and output section processes data from PC boards and components for assembly. The processor section calculates assembly operations and verifies the assembly requirements and specifications. The memory section stores data and instructions. Finally, the control section synchronizes the operation of all subsystems and monitors the assembly process. ASYS PS 30 is a cost-effective and reliable pc board assembly and manufacturing tool. It is capable of processing complex components on boards quickly, accurately, and without disruption. The reliable nature of the asset makes it perfect for small and medium-scale production. The model also features a wide range of accessories to meet the specific needs of different applications.

There are no reviews yet