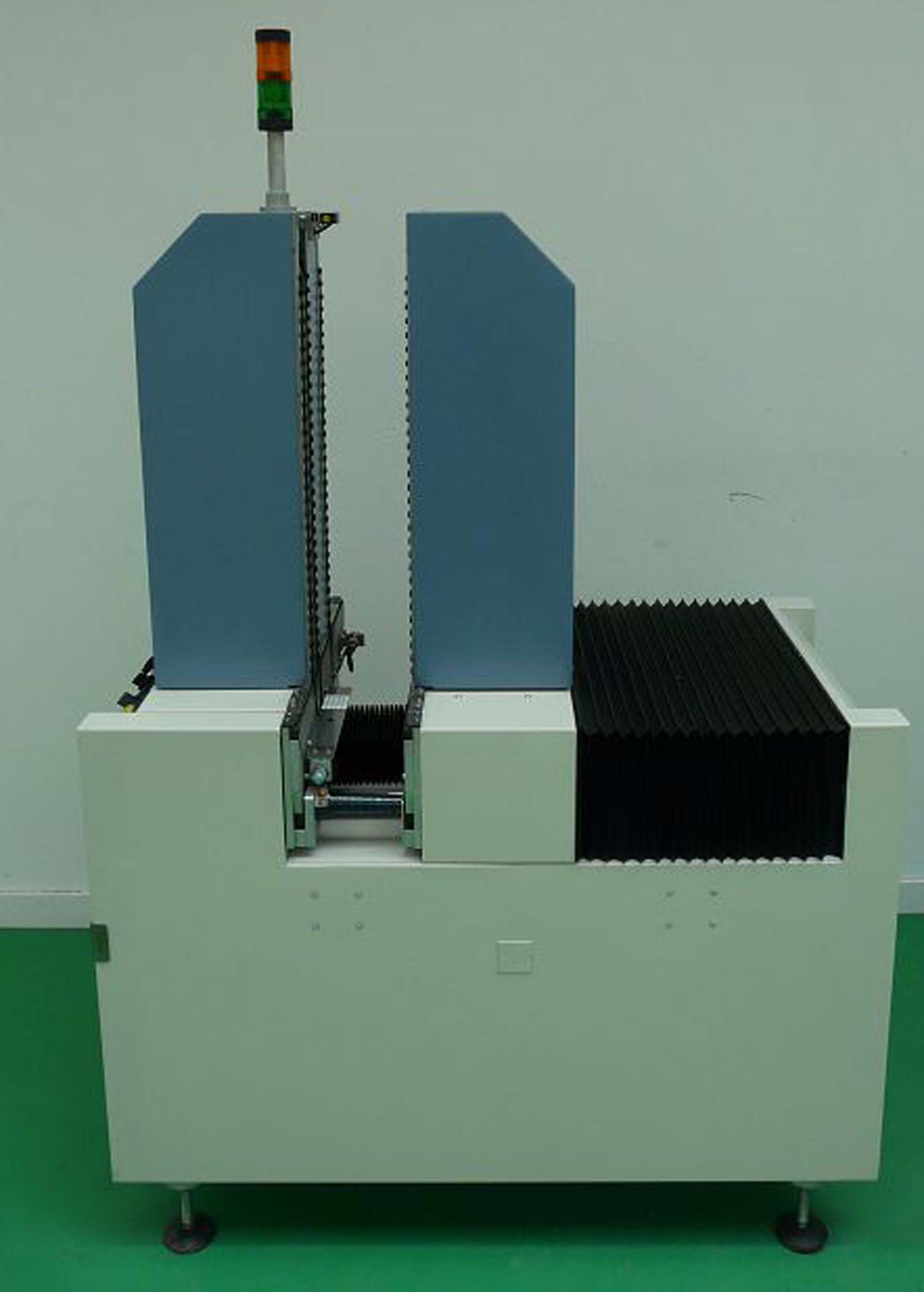

Used ASYS PS 40 #9245049 for sale

URL successfully copied!

Tap to zoom

ID: 9245049

Vintage: 2007

LIFO Buffer

Conveyor width: 50 x 460 mm

Electrical width adjustment

Transport direction: Left to right

2007 vintage.

ASYS PS 40 is an automated pc board assembly and manufacturing equipment designed to provide manufacturers with superior speed, performance, and precision. The system offers a modular design, allowing for quick and easy configuration to accommodate production requirements and component density. The unit is capable of managing up to four production lines which can work independently or in tandem, allowing for greater flexibility to meet changing production requirements. The machine is equipped with a multi-camera 3D vision machine to enable positional accuracy and alignment of components, with support for a variety of placement types including SMT, press fit, and through-hole, with an achievable placement rate of up to 80,000 cph. Additionally, the tool is capable of handling board sizes up to 510 x 610 mm and board thicknesses up to 4 mm. The asset is also designed to offer efficient, high-speed production, featuring feeder belts for quick product changeover, a conveyer model for product transportation and buffering, as well as a tensioning equipment for registration accuracy. The system is also equipped with a high-speed pick-and-place head, featuring a precision valve for accurate placement of components, servo-driven synchronous spindles for placement of parts on uneven surfaces, and integrated wafer and tray handling hardware for added flexibility. Additionally, the unit is designed for quick and easy setup, featuring a visual control command platform for streamlined operation. The machine also comes equipped with a flexible inspection tool, providing on-the-fly component verification against production and database specifications. The asset can also be connected to external process modules via an electric interface, such as external component testers, reflow ovens, and renamer devices, allowing for more efficient operation. Lastly, PS 40 is designed to minimize downtime, featuring an automated maintenance procedure model for quick troubleshooting and repair. It also offers a variety of machine guarding solutions for greater safety, such as machine mounted laser safety curtains, covering a wealth of safety areas.

There are no reviews yet