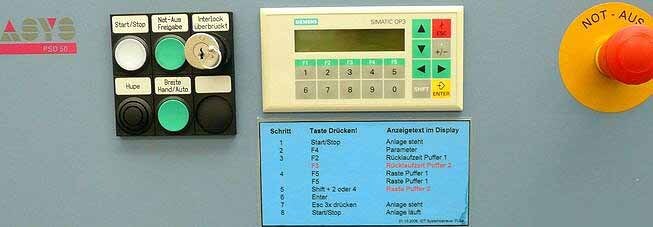

Used ASYS PSD 50 #9162596 for sale

URL successfully copied!

Tap to zoom

ID: 9162596

Vintage: 2002

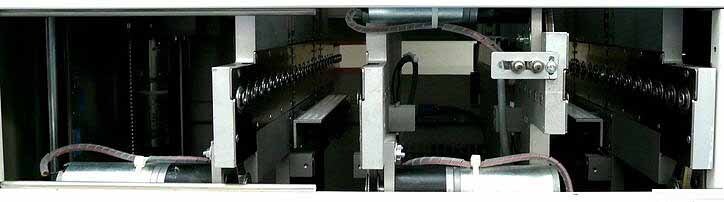

Dual lane LIFO PCB buffer

For 2x(50) PCB's

PCB size: 70x75 up to 460x168 mm

2x1 Conveyor stage, L>R

2002 vintage.

ASYS PSD 50 is an advanced, fully automated pc board assembly and manufacturing equipment designed for efficiently mass-producing high-end custom pc boards. The system provides a cost-effective solution for small, medium, and large volume productions of pc boards. It is capable of producing up to 50 boards per hour on a standard 24" x 36" pc board. PSD 50 unit is composed of a frame, conveyor machine, PC station, and a robotic arm. The conveyor tool transports the pc board from the first to the last station. At the PC station, the board is inspected by an automated camera for any physical anomalies. Once determined to be defect-free, the board is then sent to the robotic arm which is specifically designed for pc board assembly. The robot is programmed with a robot-specified feeder to pick up components and accurately assemble them to the board. Once all components have been assembled, the board is then sent off to the next station for further quality assurance. To maintain high-quality standards ASYS PSD 50 is equipped with various technologies, such as an optical defect asset and flux management model. The optical defect equipment uses a vision camera to detect tolerances, size errors, and solder joint integrity. The flux management system constantly monitors the flux supply level to make sure that the proper amount of flux is added for optimal solder results. Additionally, the unit is highly modular and adaptable, so it can be customized to each customer's needs. This includes multiple software platforms such as a programming app that allows for easy programming and storage of recipes. The machine also has self-diagnostic capabilities to quickly locate faults and allow for interface and tool diagnostics. PSD 50 is a major asset in the pc board manufacturing industry because it is cost-effective and highly efficient in producing high-quality boards in minimal time and effort. Its versatility and ability to meets customers' specific needs are just some of the reasons why the asset is one of the best in the industry.

There are no reviews yet