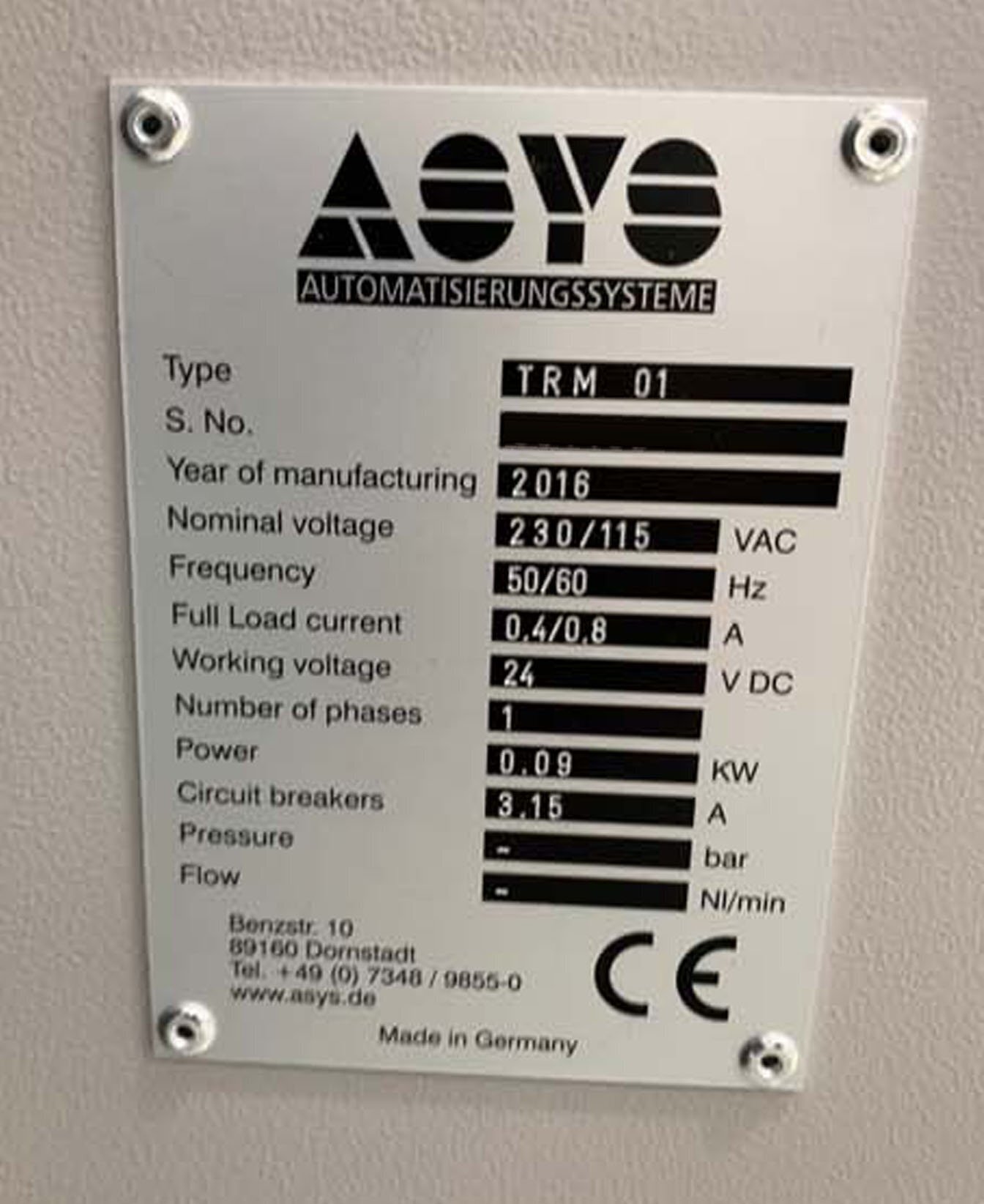

Used ASYS TRM 01 #9301066 for sale

URL successfully copied!

Tap to zoom

ASYS TRM 01 is a computerized pick and place assembly machine designed for printed circuit board (PCB) manufacturing. The equipment is capable of processing a variety of components on one piece of equipment, including chip feeders, machine vision systems, and optional Solder Paste Inspection (SPI) capabilities. The system is equipped with an onboard H-shaped gantry designed to move a vacuum mounted PCB to request sites for loading, unloading and in-process positioning. A two-axis mini-positioner manages an array of nozzles that collect components from a feeder and place them onto the board. The two-axis linear motion offers low torque, a larger mechanical travel and precise positioning. TRM 01 is designed for maximum flexibility and quick changeover times, allowing it to easily accommodate low and medium-volume production. A wide variety of component packages can be placed with accuracy, including SOTs, SOICs, 28mm QF and others. The unit supports up to 84 pick and place heads, allowing for a variety of applications such as high mix/low volume production, higher throughput and more complex board designs. Additionally, the machine offers high-speed vision inspection and optional SPI runs with a single click. Up to 50 job files are saved and can be recalled at any time for quick setups and rework. The user interface for ASYS TRM 01 is intuitive and easy to use. Its graphical control panel allows for simple job programming and setup. It also gives the operator control to monitor and adjust components per job, production speed and machine output. Each axis has an automatic shut off to prevent collisions when unexpected pauses in the cycle occur. Additionally, the machine is equipped with an automated calibration machine that ensures high accuracy with multiple camera measurements. TRM 01 is designed with safety in mind. It complies with safety standards, including CE and UL requirements, and features an emergency stop feature, two light curtains and two e-stops. Other design features include a sophisticated, lid-less mounting tool for moisture relief and improved airflow. The machine also features lift detection functions that ensure safe component placement. Overall, ASYS TRM 01 offers a reliable, efficient and precise pick and place asset that is suitable for a variety of PCB production needs. The model is flexible, accurate and user-friendly, providing an efficient, cost-effective solution for small-to-medium PCB production.

There are no reviews yet