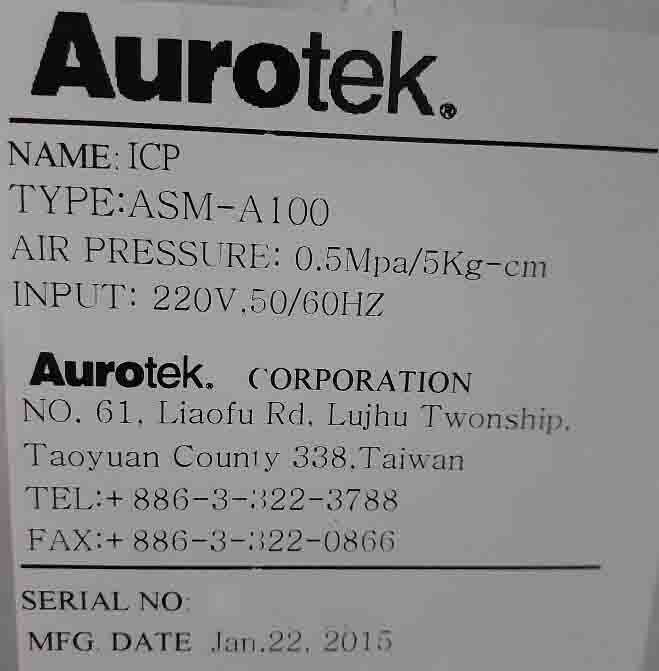

Used AUROTEK ASM-A100 #293655301 for sale

URL successfully copied!

Tap to zoom

ID: 293655301

Wafer Size: 2" - 4"

Vintage: 2015

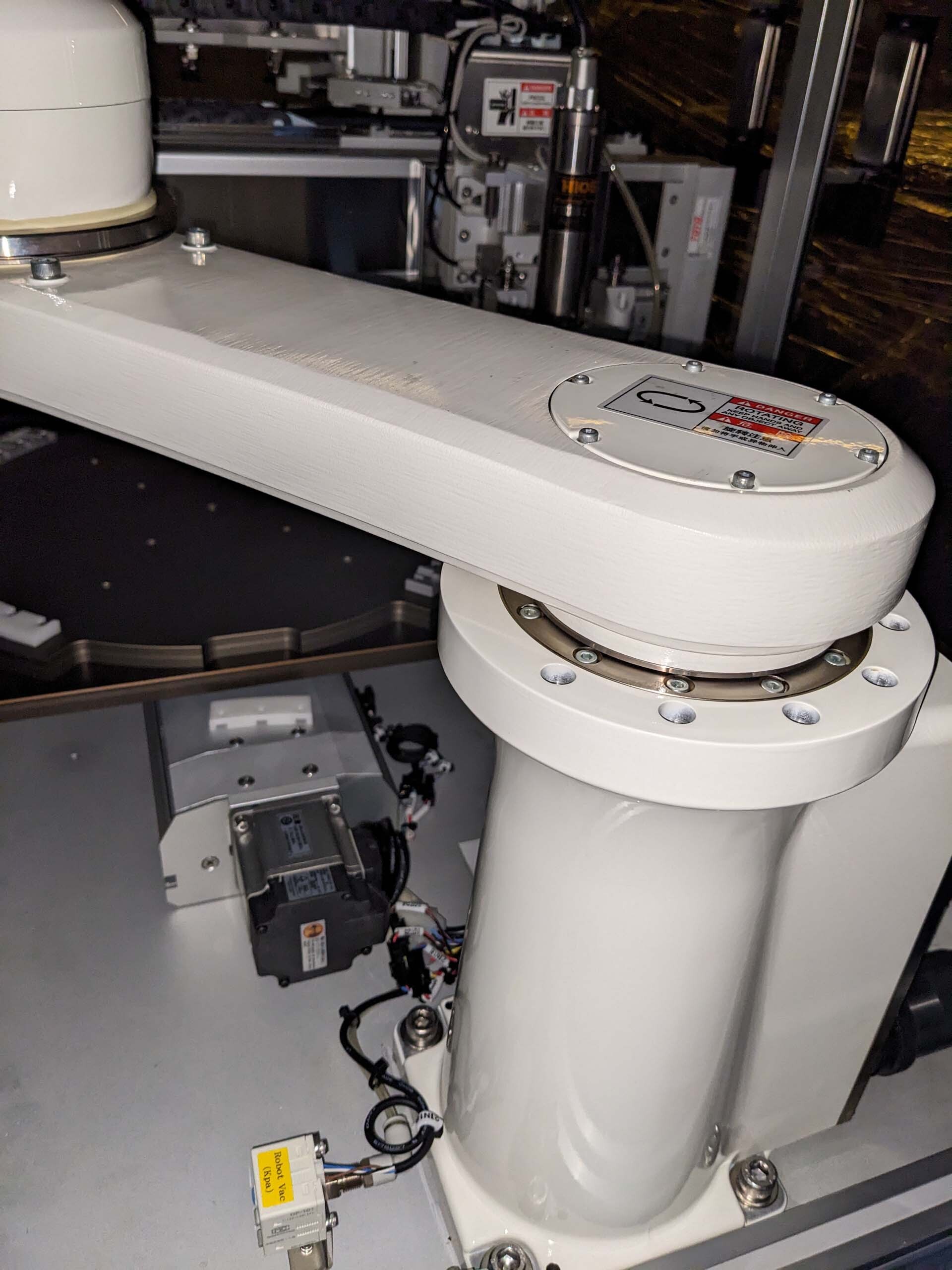

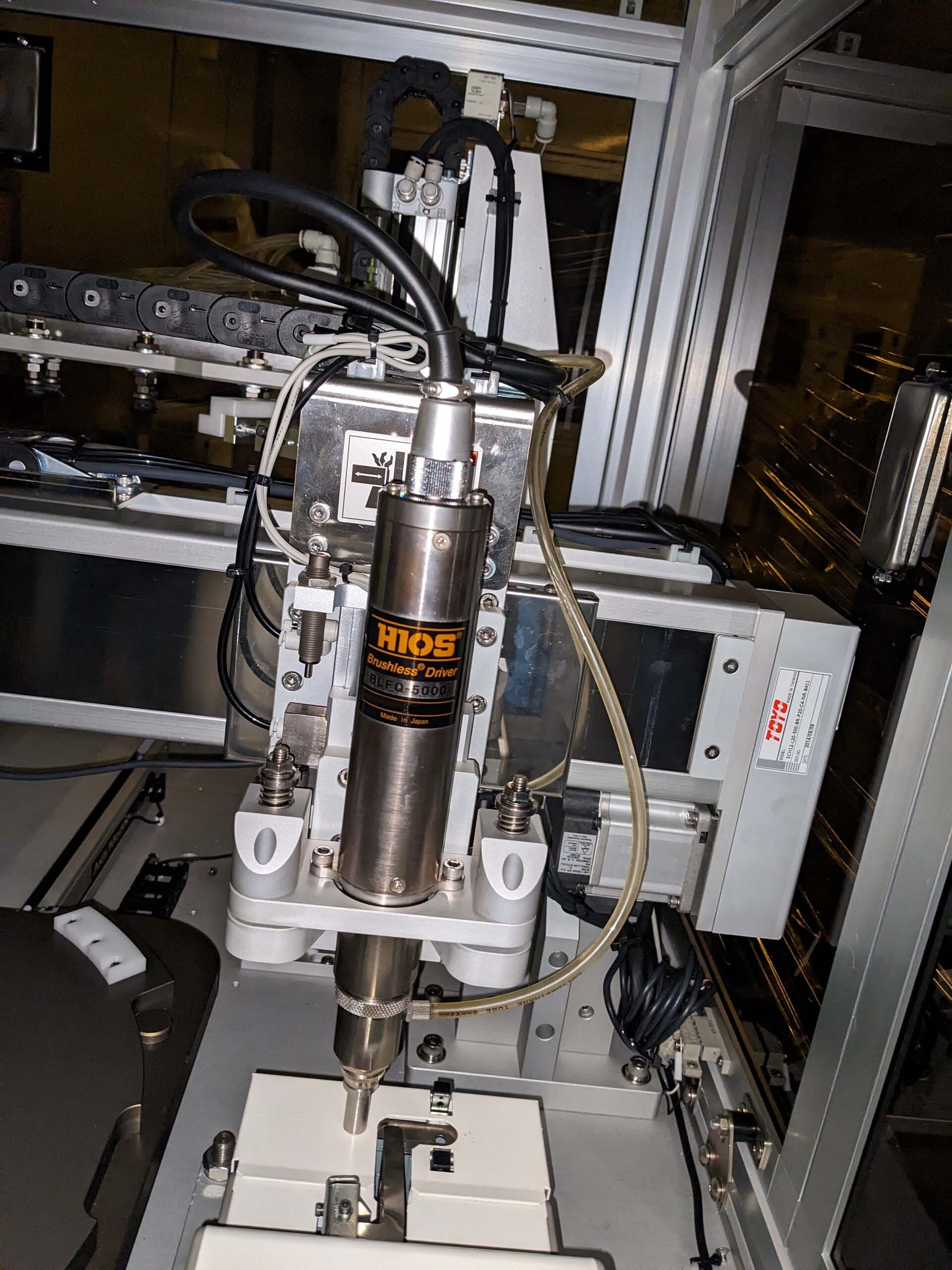

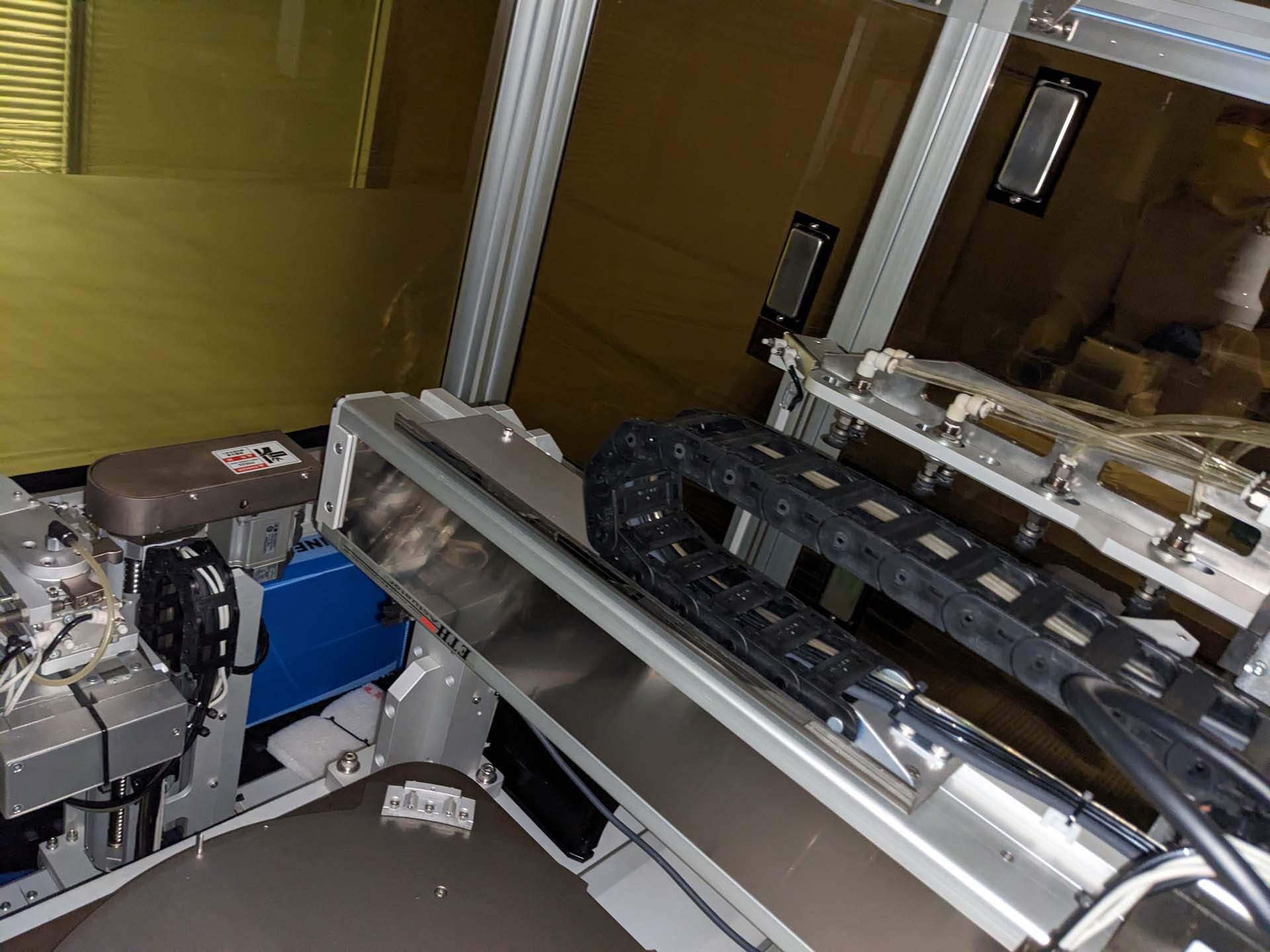

ICP Automatic loader, 2"-4"

2015 vintage.

AUROTEK ASM-A100 is an advanced production line equipment for pc board assembly and manufacturing. This state-of-the-art system is designed specifically for users who require high levels of accuracy and efficiency in their processes. ASM-A100 is a comprehensive automated assembly and manufacturing unit, capable of creating high-quality pc boards with minimal user intervention. This machine is comprised of several sub-components, including a scanning/pick-and-place station, a mounting/soldering station, and a quality control station. The scanning/pick-and-place station is the first component of AUROTEK ASM-A100 tool. This station is equipped with sophisticated optical recognition software, which scans and identifies components of the pc board, such as surface mount components. Once identified, these components are picked up by the asset and placed onto their allocated spots. This process results in accurate placements of all components on the pc boards. The second component of the model is the mounting/soldering station. This station is equipped with high-speed and high-precision soldering systems. It uses advanced technologies, such as optical targeting, to ensure accurate and repeatable soldering, providing flawless joints with no solder bridges. In addition, the station is designed to produce minimal and consistent waste material. The third component of the equipment is the quality control station. This station is responsible for ensuring that the pc boards meet customer requirements. It uses advanced optical inspection and x-ray inspection technologies to detect any defects on the pc boards. Additionally, the station is capable of measuring different electrical and mechanical characteristics of the pc boards. Once any detected faults have been identified, corrective action can be taken to fix them. ASM-A100 has been designed to minimize production waste and minimize human error. The system automates and manages the entire production process, from scanning and placement of components, through to soldering and quality control. This automated production process results in higher PCB yields, reduced production times, and decreased costs for manufacturers. The unit is also highly reliable, as it has been rigorously tested by the manufacturer and is certified for use in industrial environment. Overall, AUROTEK ASM-A100 machine is the perfect solution for manufacturers requiring high levels of accuracy and efficiency in their pc board assembly and manufacturing processes. This state-of-the-art tool provides an efficient, automated production process and helps to improve yields and reduce costs.

There are no reviews yet