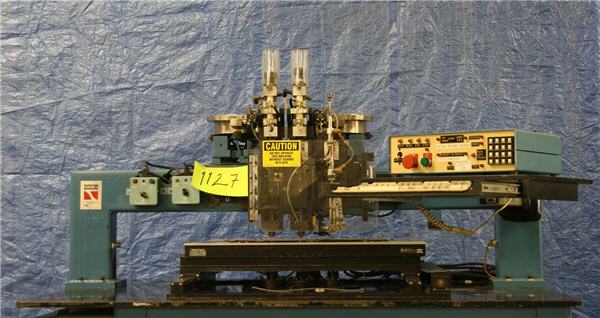

Used CAMBRIDGE HM 2424 #130140 for sale

URL successfully copied!

Tap to zoom

ID: 130140

Socket inserter

(Qty 3) independent heads

Maximum board size: 20" x 20"

Head configuration:

(Qty 3) CAMBRIDGE MM-425-18CC headas

Footprint: 66"L x 54"W x 72"H

120 VAC, 30A, 80 to 125 PSI.

CAMBRIDGE HM 2424 is a pc board assembly and manufacturing equipment designed to increase productivity and efficiency for a variety of industrial applications. It is a cost-effective solution for small to medium-sized businesses and manufacturers who need reliable and high-quality pc board assembly. The machine is equipped with an advanced automatic soldering process and is capable of high-precision placements that meet the highest quality standards. The Cambrige HM 2424 utilizes an advanced vision system with superior scanning and recognition capabilities. This unit increases accuracy and speed of placement and soldering as well as corrosion protection. The registration process is also completed in milliseconds for seamless integration with existing designs. CAMBRIDGE HM 2424 offers several assembly process options which include high-speed solder paste printing, selective soldering and lead-free soldering. It also provides the ability to process various components such as capacitors, resistors, triggers, diodes and other solderable parts. Through the use of modern touch-screen controls, the operator is able to quickly and easily see, adjust and monitor the machine's performance. HM 2424 is designed to cut costs and provide high-quality production. It eliminates manual errors and reduces labor costs and operating expenses. The machine can adjust automatically to changing board thickness and can work with a variety of board types. The machine is constructed with a durable and solid steel frame and can easily be integrated with other machinery and processes. CAMBRIDGE HM 2424 also offers increased safety features. The machine is equipped with numerous safety mechanisms, such as emergency stop buttons, and alarms to indicate incorrect placement, soldering issues and temperature changes. The machine's sophisticated vision machine is also programmed to detect and avoid accidental contact and/or force with components. HM 2424 offers improved accuracy, quality and efficiency for pc board assembly and manufacturing operations. The machine is designed to reduce setup time and the overall cost of production while still providing reliable, high-quality results that meet the highest standards. The combination of advanced vision tool, precise placement and soldering capabilities, and safety features make CAMBRIDGE HM 2424 a cost-effective and efficient solution for industries looking to increase productivity and efficiency.

There are no reviews yet