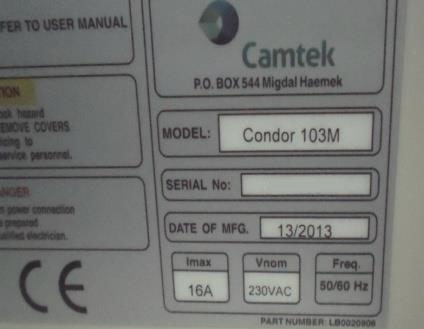

Used CAMTEK Condor 103M #9255455 for sale

URL successfully copied!

Tap to zoom

CAMTEK Condor 103M is a robotic PC board assembly and manufacturing equipment that enables quick and efficient placement of surface-mount components. This system can be used to produce low-medium complexity, industrial-grade electronic components and assemblies with speed and precision. Condor 103M features two high-speed PAN/TILT head modules and a mounting and alignment unit for different size components. It also has a vacuum machine to pick up and place components accurately and compact robotic arms to perform precise movements. The tool is equipped with a high-end industrial vision asset that utilizes a 3D camera to monitor the component placement in real time. This ensures that all components are placed accurately and on the correct pad positions. The vision model also verifies the correct orientation of components before placing them on the board. Furthermore, the equipment can measure component skew and allows for correction of any offsets. CAMTEK Condor 103M uses a unique six-axis robotic control unit that enables it to place components quickly and accurately. The system also offers dual-background camera vision and flash soldering capability. The built-in vision and machine learning algorithms enable it to recognize and adjust to different components automatically. This increases production efficiency and reduces common firmware-based errors. The unit also provides an interactive user interface for easy programming and control. Condor 103M machine is designed for quick placement of components with various sizes and shapes. It can be used for electronics prototypes to medium-volume production in the fields of industrial control, automotive electronics, telecommunication systems, medical instruments, and consumer electronics. This tool is highly reliable and provides an excellent return on investment.

There are no reviews yet