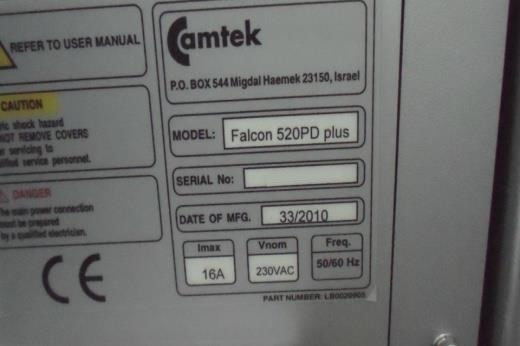

Used CAMTEK Falcon 520PD Plus #9256045 for sale

URL successfully copied!

Tap to zoom

CAMTEK Falcon 520PD Plus is an innovative and efficient production equipment designed to simplify the process of assembling and manufacturing printed circuit boards (PCBs). This system features an array of advanced capabilities to streamline the PCB manufacturing process. Falcon 520PD Plus features an intuitive Human Machine Interface (HMI) that allows users to quickly and easily manage and monitor various operations related to the assembling and production of PCBs. The unit allows for precise positioning of components with sub-micron accuracy, making it ideal for mass production. It also features vision-guided robot technology, which allows the machine to recognize specific components and assign actions. This technology also makes it possible to recognize defects in the PCBs and sends out a signal to alert users. The tool is equipped with pick-and-place machines to make the assembly process faster and more accurate. There are top feed and bottom feed pick-and-place machines which can be programmed with different feed speeds and alignment curves. This makes it possible to optimize the assembly process for different types of PCBs. It also features a quick-change nozzle design that allows users to quickly switch between nozzle heads for different applications and a universal nozzle adapter. This makes it easy to quickly switch between different nozzles for every production application. CAMTEK Falcon 520PD Plus is designed to be highly efficient, allowing users to reduce labor and overhead costs. It is designed to be a safe and reliable machine. It features a safety switch and a top-opening lid design for easy access to the internal components. Falcon 520PD Plus asset is also environmentally friendly, as it features a low power consumption when in sleep mode. Additionally, it can be easily upgraded, allowing users to update the model as needed. Overall, CAMTEK Falcon 520PD Plus is an efficient and reliable production equipment that can greatly reduce labor and overhead costs while maintaining a high level of quality for assembling and manufacturing PCBs. Its intuitive HMI, precise positioning, and vision-guided robot technology make it an ideal solution for mass-producing PCBs.

There are no reviews yet