Used CAMTEK Falcon 820 #9265583 for sale

URL successfully copied!

Tap to zoom

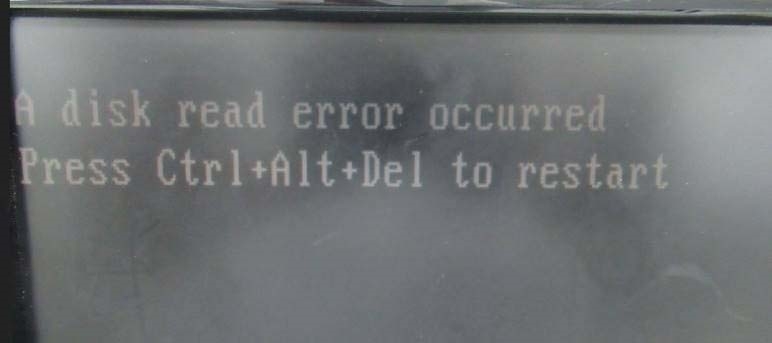

ID: 9265583

Wafer Size: 6"-8"

Vintage: 2006

System, 6"-8"

Automatic loading

With wafer ID reader (OCR)

2006 vintage.

CAMTEK Falcon 820 is a complete PC board assembly and manufacturing equipment designed for superior productivity and flexibility. This system utilizes advanced technology and automated process control to streamline and optimize the entire printed circuit board production process. It is a turnkey solution that can help manufacturers meet their goals of high-quality, cost-effective and reliable production of PC boards. Falcon 820 features a production line design that includes a high-speed pick and place machine, a board staking unit, a screen printer with integrated vision machine, a board inspection tool with 3D image scan, and a fluxer and oven for reflow soldering. It can be easily integrated into existing manufacturing and workflow systems, allowing for extensive customization for efficient production. The asset is designed to reduce the risk of errors while increasing production accuracy. The high-speed pick and place machine is capable of automatically loading components onto the PCBs with high precision. It is equipped with a built-in vision model to ensure accurate placement of components and can handle a variety of component sizes and types. The board staking equipment provides secure and reliable soldering connections for a variety of materials. The screen printer has a built-in vision system to ensure accurate placement of solder paste on the board. The board inspection unit utilizes a 3D image scan to detect possible solder shorts and opens on the PC boards. It has the ability to inspect, detect, and reposition components on the board if necessary. The fluxer and oven are used for reflow soldering, ensuring a tight and secure connection between the components and the board. The machine automatically adjusts the settings to ensure a consistent and reliable soldering process. CAMTEK Falcon 820 is an ideal solution for high-volume PC board assembly and manufacturing. It is designed for increased automation and accuracy while offering a comprehensive solution for production efficiency. The tool has the capability to easily integrate into existing infrastructure, allowing for quick and efficient production with minimal problems. With the help of this asset, manufacturers can significantly reduce their time and costs while producing high-quality, reliable boards.

There are no reviews yet