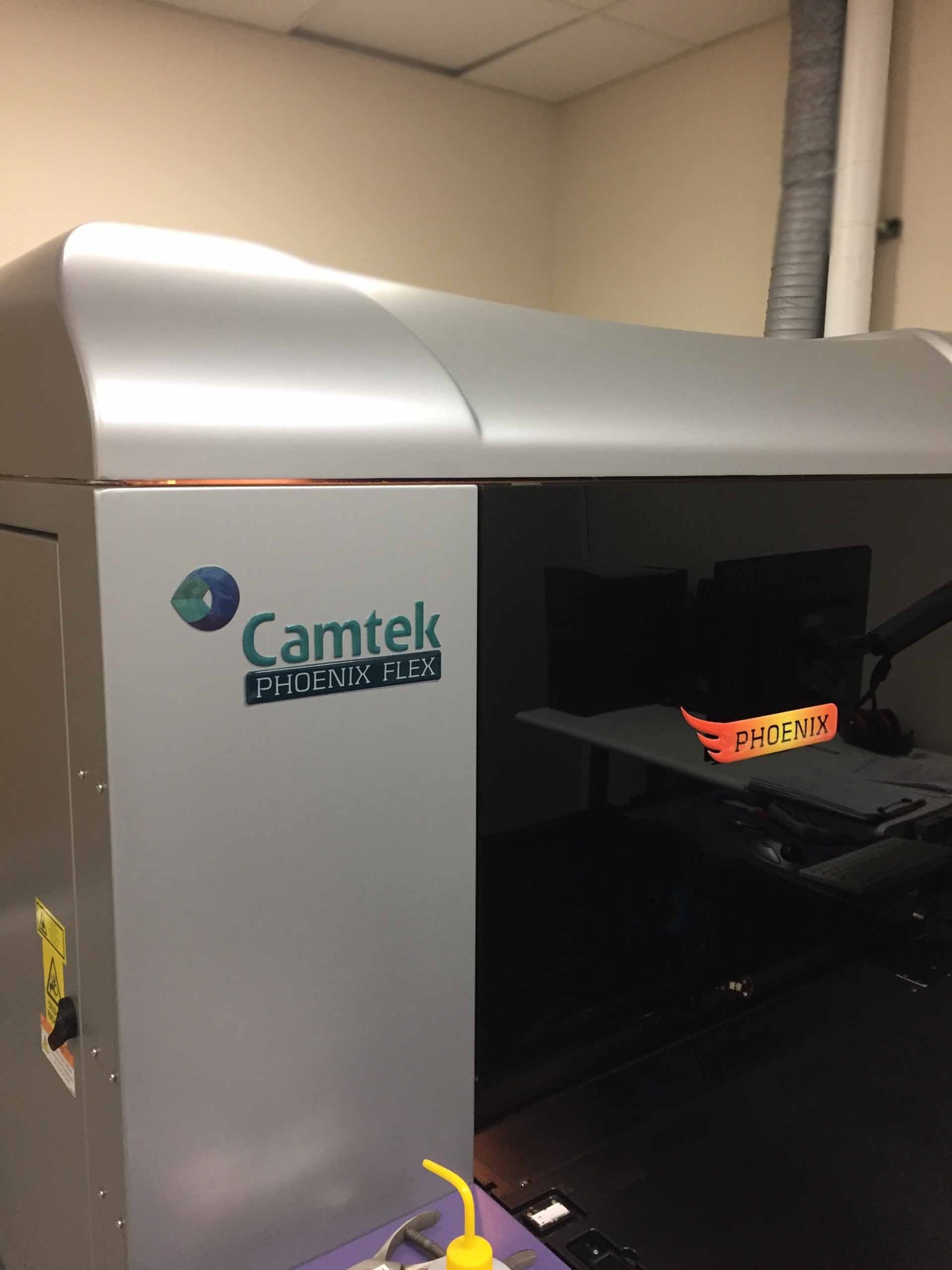

Used CAMTEK Phoenix #9227751 for sale

URL successfully copied!

Tap to zoom

ID: 9227751

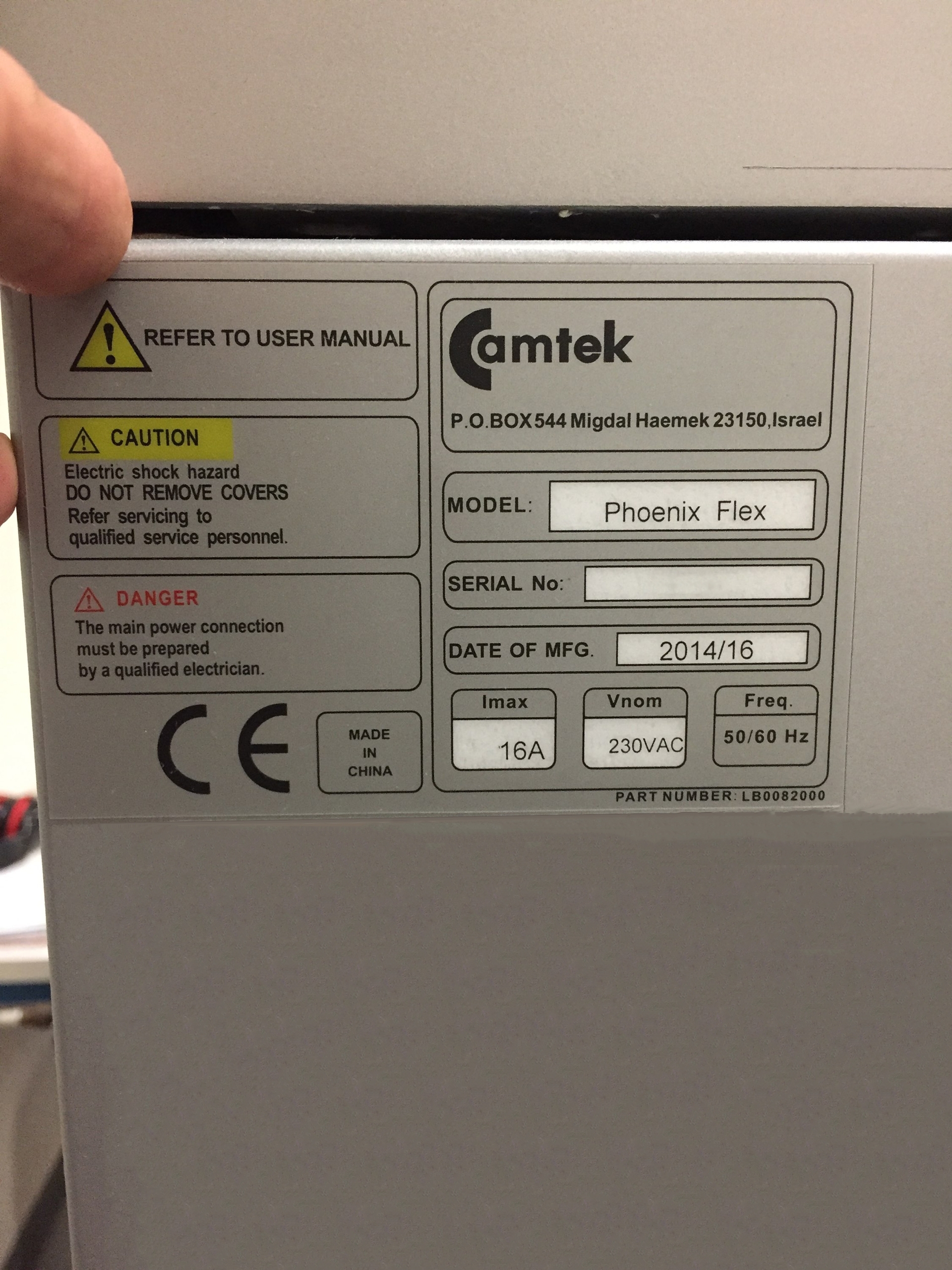

Vintage: 2014

Automatic Optical Inspection (AOI) system

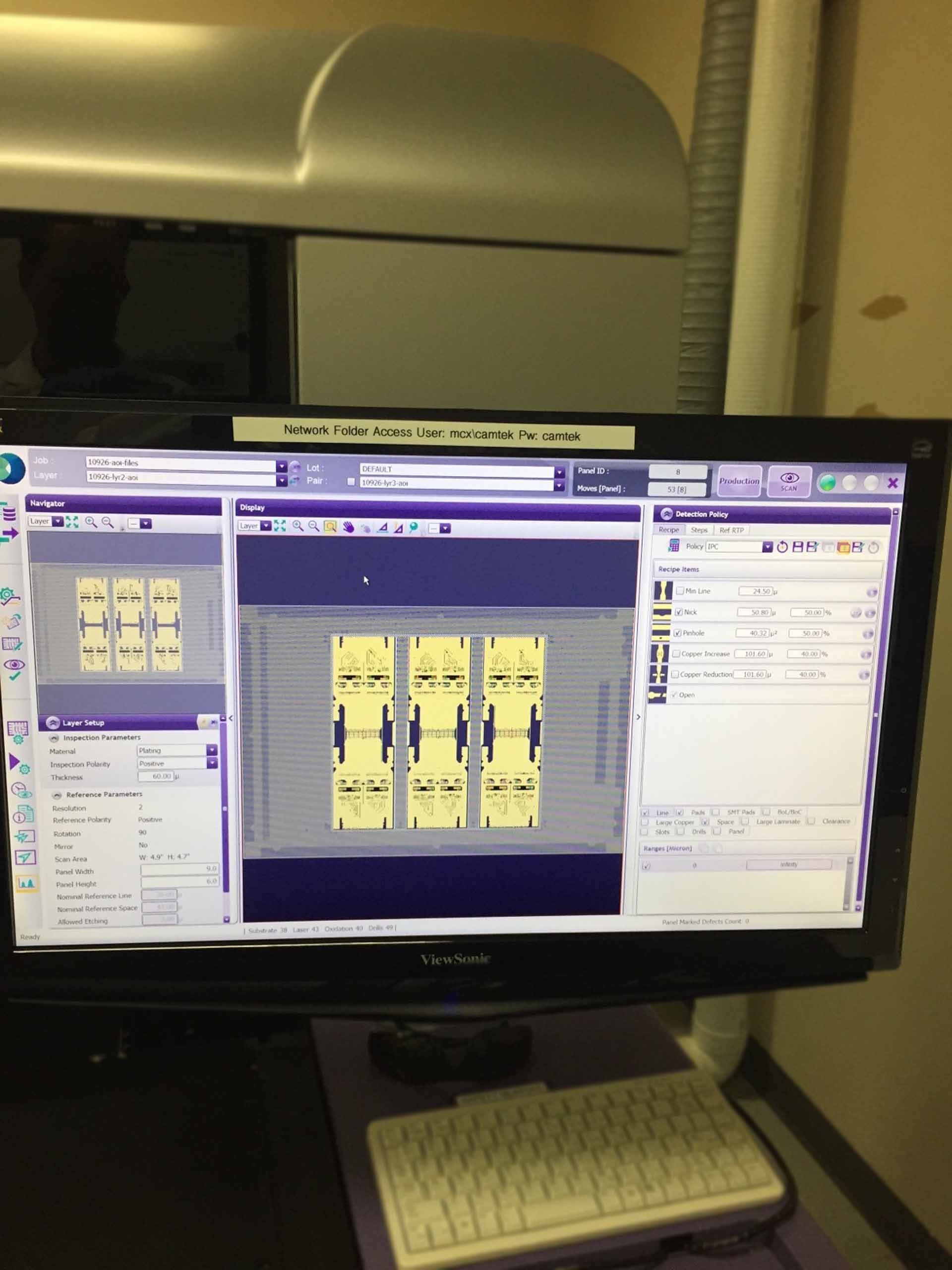

Superior detection with optimal ratio:

Between critical defects and non-critical defects

Lowest missing rate

Simple and quick setup

Range: 1 mil (25μm) - 6 mil (152μ) line and space technology

Up to 260 sides/Hour

Size: 24"x18" @100μm L width

PCB: Down to 50μm line / Space

Throughput: Up to (220) sides / Hour

Panel size maximum: 21" x 26" (762 mm x 660 mm)

Panel thickness range: 1-200 mil (0.025 - 5 mm)

Panel types and designs: Flex printed circuits board

Optical resolution :

Minimum pixel size: 6 micron

Materials:

Plated copper

Gold plating

Silver-halide

Diazo

Photo-resist

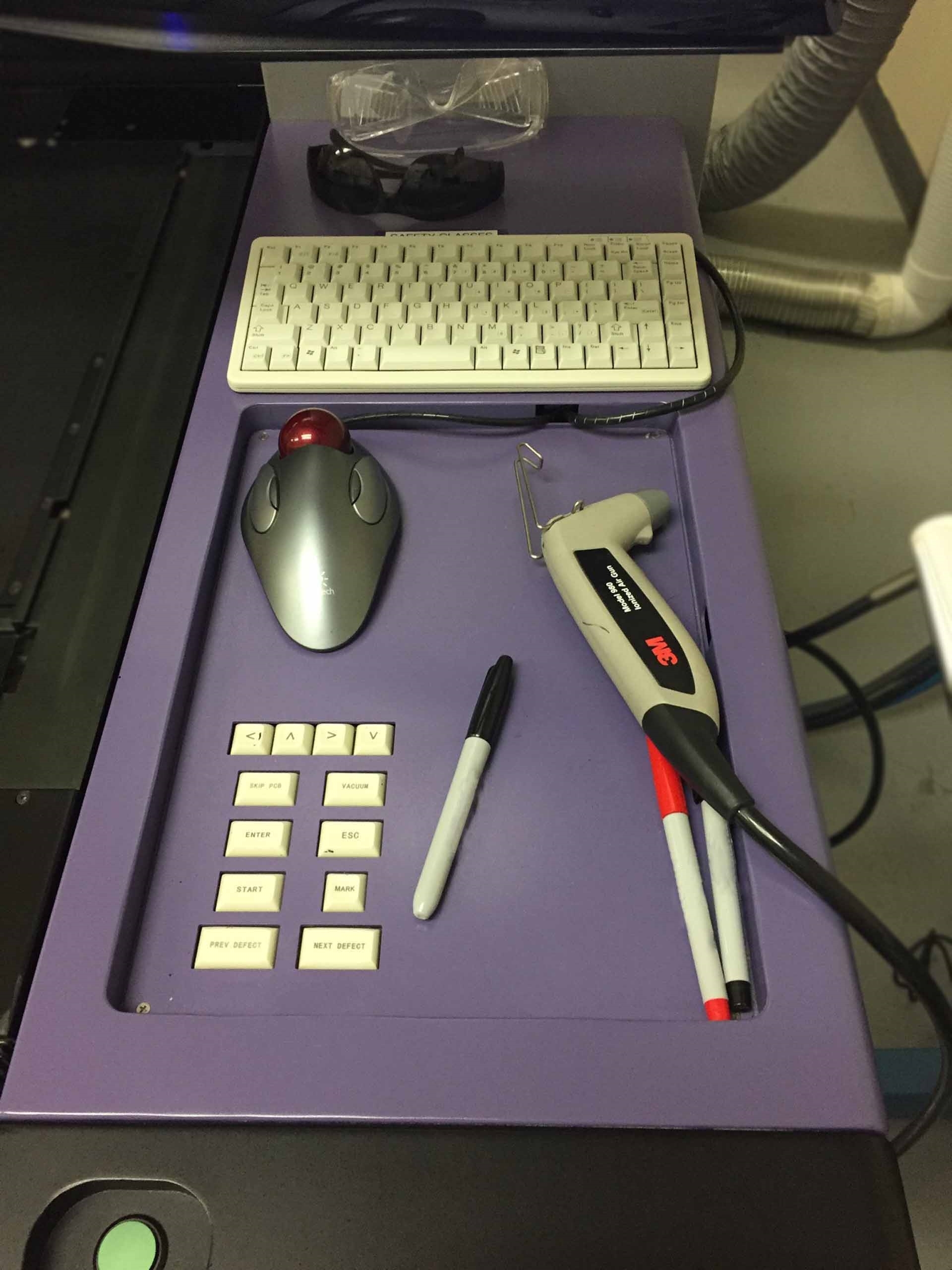

System components:

Accurate and silent motion

Robust structure

Advanced vacuum table

Optic device for superior image acquisition

Firmware for image processing

Powerful processors to handle high density PCB

MZ, MS, SPARK Multi zone detection

Microlight:

Detection on fine shots

Dishdowns

Image acquisition:

Digital black and white scanning camera

Analog color live verification camera

Detectable defect types:

Open and short circuit

Nick

Protrusion

Mouse-bite

Pinhole

Island

Dish-down

Line / Space width violation

Annular ring violation

Source data: CAM

Tooling: Pin-less

EMC:

EN 61000-4-2

EN 61000-4-4

EN 61000-4-6

EN 61000-4-11

EN 61000-6-1

EN 55011

Compressed air: 6 ATM, 1 l/min

Temperature and humidity: 22 ± 3°C; 50 ± 10%RH

Includes:

Online Registration (OLR)

Flex image enhancement inspection

Off-line reference system

Photo Resist Inspection (PRI)

Low contrast materials

Operating system: Windows 7

Power requirements: 100/240 VAC, 50/60 Hz, 2.5 kW

2014 vintage.

CAMTEK Phoenix is an advanced pc board assembly and manufacturing equipment designed for fast, reliable, and cost-efficient production. This system provides essential tools to create, design, and assemble pc boards in one integrated platform. Phoenix is ideal for large-scale production runs, allowing the user to process multiple designs and configurable products in a single setup. It accurately places, reboots, and precisely assembles components on each pc board at speeds up to 5000 parts per hour. The unit also offers a wide selection of feeders to meet any production line requirement for pc board components. The equipment ensures fast and reliable production by delivering high accuracy and repeatability. It features surface-mount technology (SMT) 3D SPI technology to ensure high-precision placement and solder joint creation. This machine uses light fiducial markers with a resolution of 0.1mm to distinguish different components on the pc board. To reduce production downtime, CAMTEK Phoenix can operate continuously for up to 24 hours. Flexibility and process control are also essential features of the tool. The user can easily adjust and customize several aspects of the pc board, such as component placement, wave soldering, and reflow soldering. Users can also fine-tune adjustment of various components to optimize productivity. The asset also offers a user-friendly software interface to monitor production and create custom solutions for more efficient assembly. In addition to its exceptional performance, Phoenix is very user-friendly. This model offers interface tools and tailored software drivers for manual and automatic programming, which makes operating the equipment very easy. The equipment also provides the system controllers with real-time monitoring of machine status to guarantee faster and more effective production. CAMTEK Phoenix is the ideal choice for pc board assembly and manufacturing. With its high production capabilities, precision components placement, and user-friendly interface, this unit provides efficient and reliable production that meets the highest industry standards.

There are no reviews yet