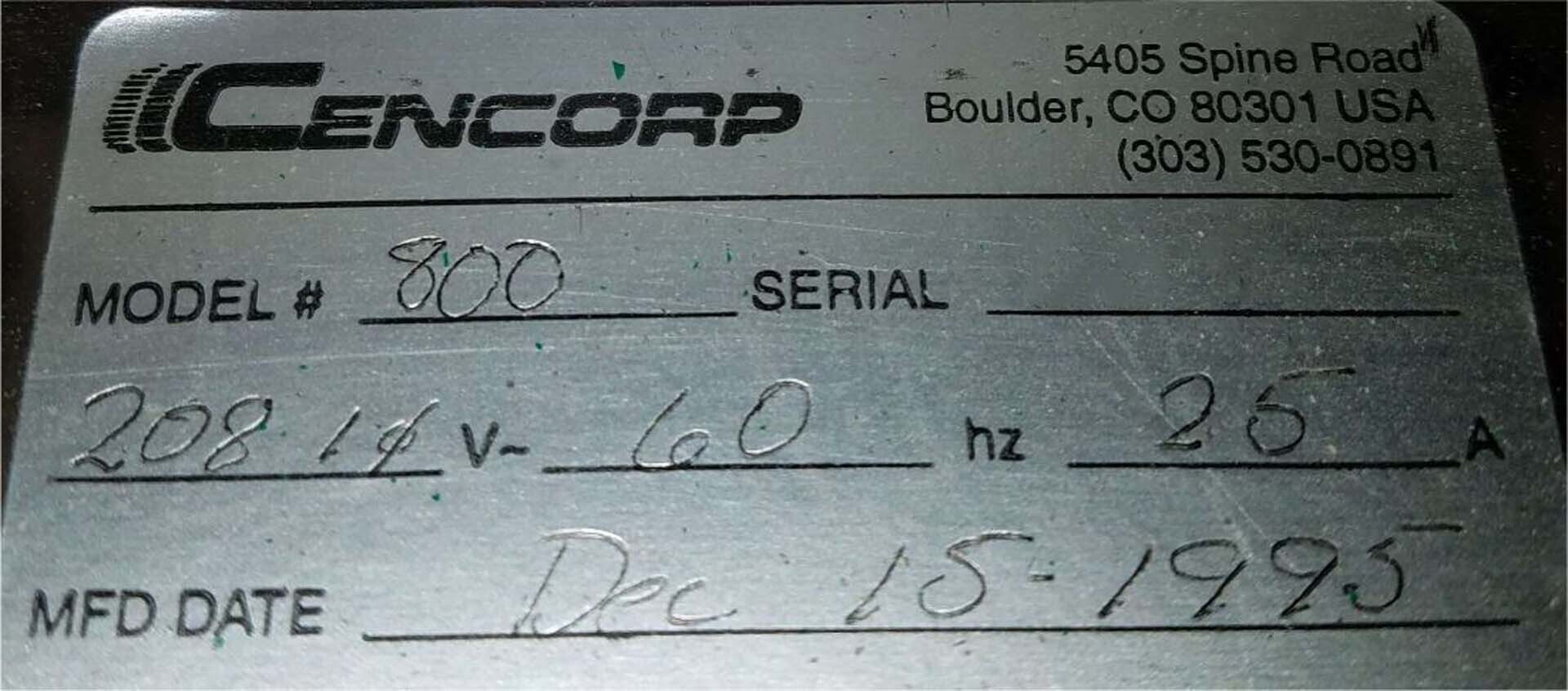

Used CENCORP TR1000 #9313438 for sale

URL successfully copied!

Tap to zoom

CENCORP TR1000 is a pc board assembly and manufacturing equipment that is capable of producing high-quality printed circuit boards with tight tolerances. This system consists of three components: a pick-and-place machine, an in-line soldering unit, and a vision inspection machine. The pick-and-place machine is the heart of the tool. It uses a vacuum-based asset to accurately place components onto the substrate and can achieve a placement accuracy of ± 0.005 inches. It is capable of handling multiple lead-free, surface mount technologies and pitch components in sizes down to 0201 body size. The pick-and-place model is also equipped with two cameras to monitor and ensure accurate placement. The in-line soldering equipment utilizes a high-power laser to heat the surface mount components soldered onto the pc board. This laser is capable of precision soldering down to 0.6 mm pitch components while maintaining a ± 0.2mm solder joint wall length accuracy. The laser is also capable of handling both lead-free and leaded solders, providing the customer with flexibility in selecting the right solder for their application. The laser is also equipped with a vision system to verify the correct soldering points and height. Finally, the unit is equipped with a vision inspection machine. This tool uses high-resolution cameras to measure the components for placement accuracy, alignment, and orientation, as well as the solder joints for defects including shorts, opens, and bridging. It also has a tooling asset to measure specific components for coplanarity and overall repeatability. Overall, CENCORP TR 1000 is an innovative and high-performance pc board assembly and manufacturing model. The integrated pick-and-place, soldering and vision inspection systems make this equipment a reliable and trustworthy choice for any pc board assembly needs.

There are no reviews yet