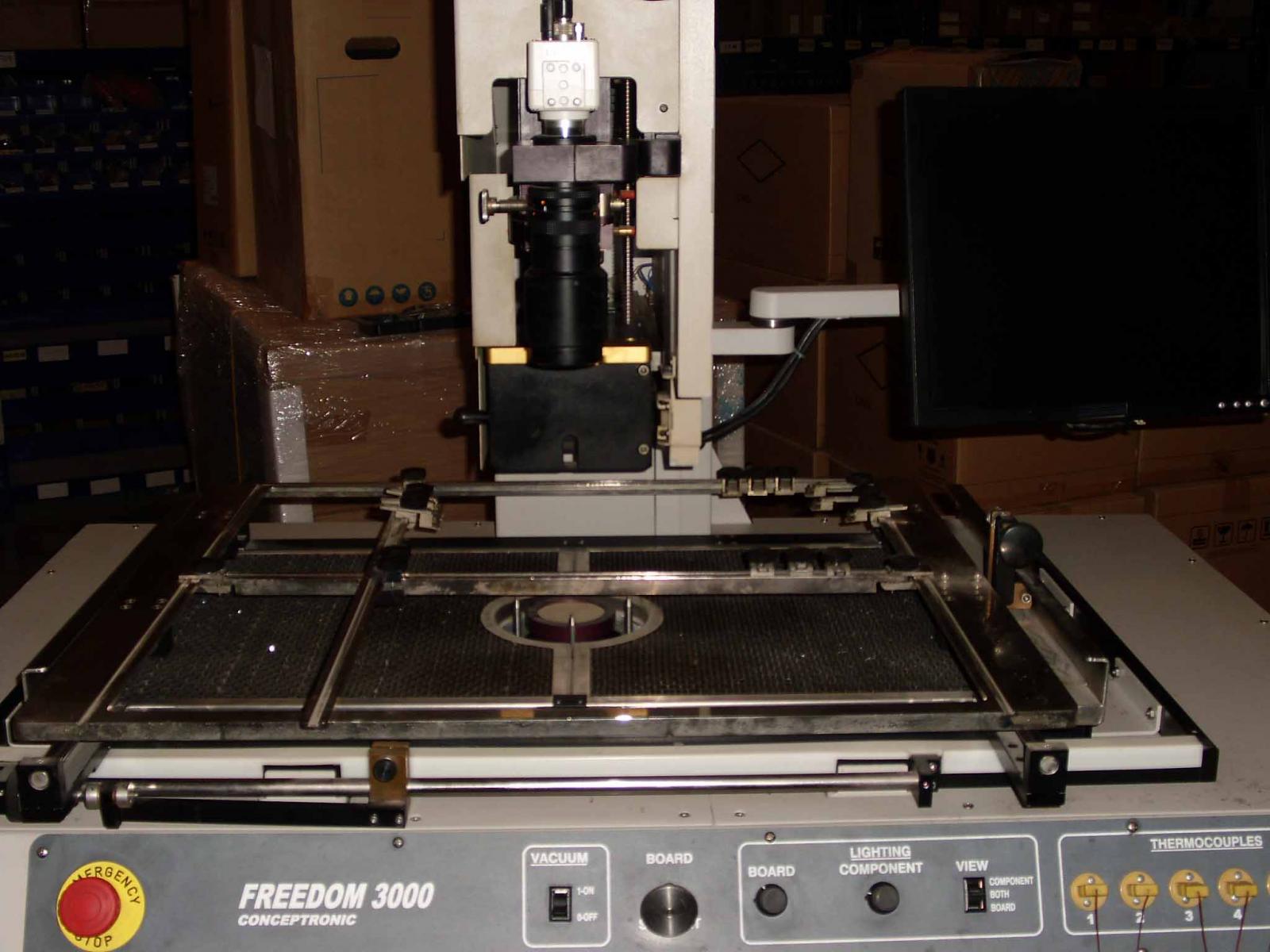

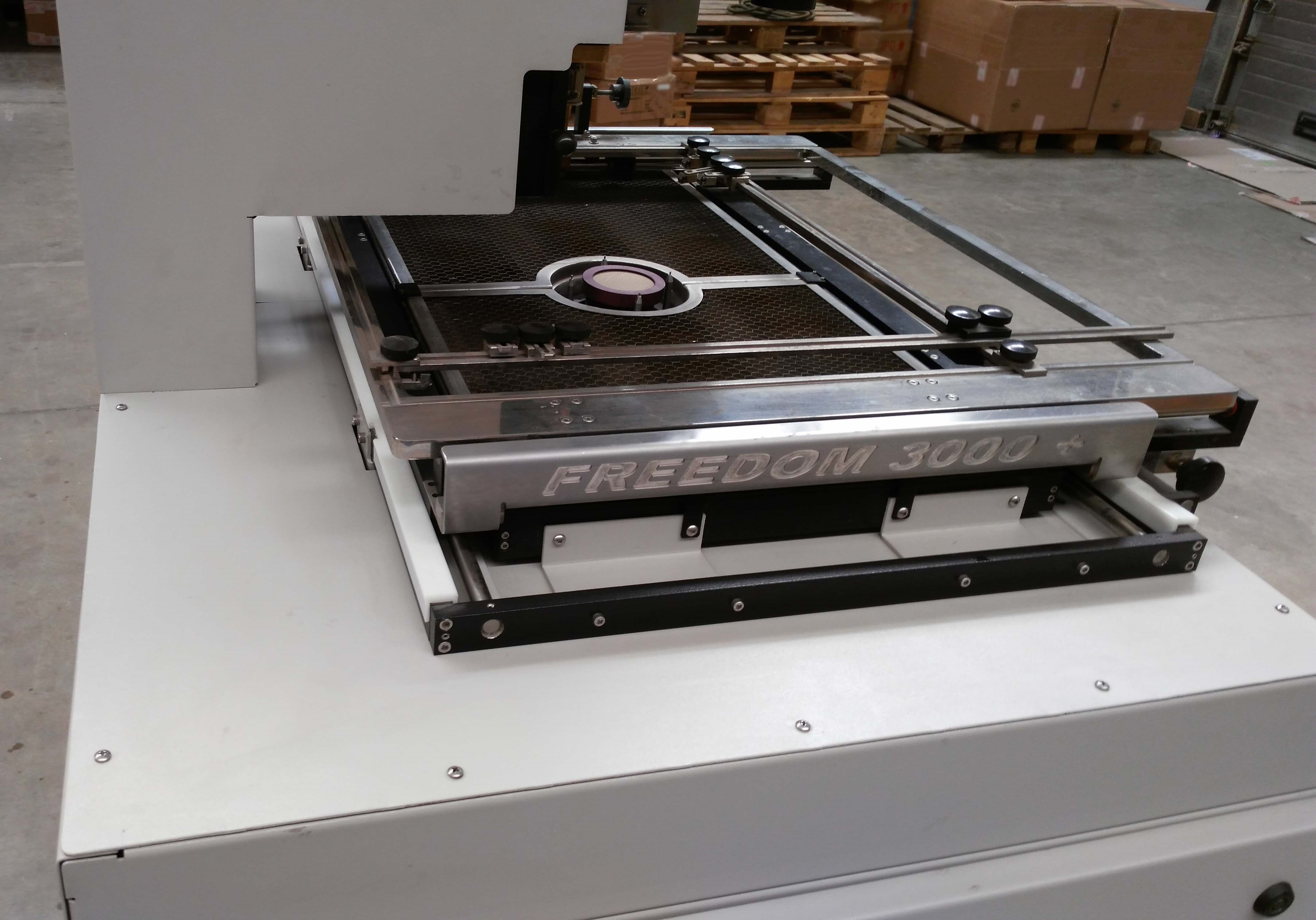

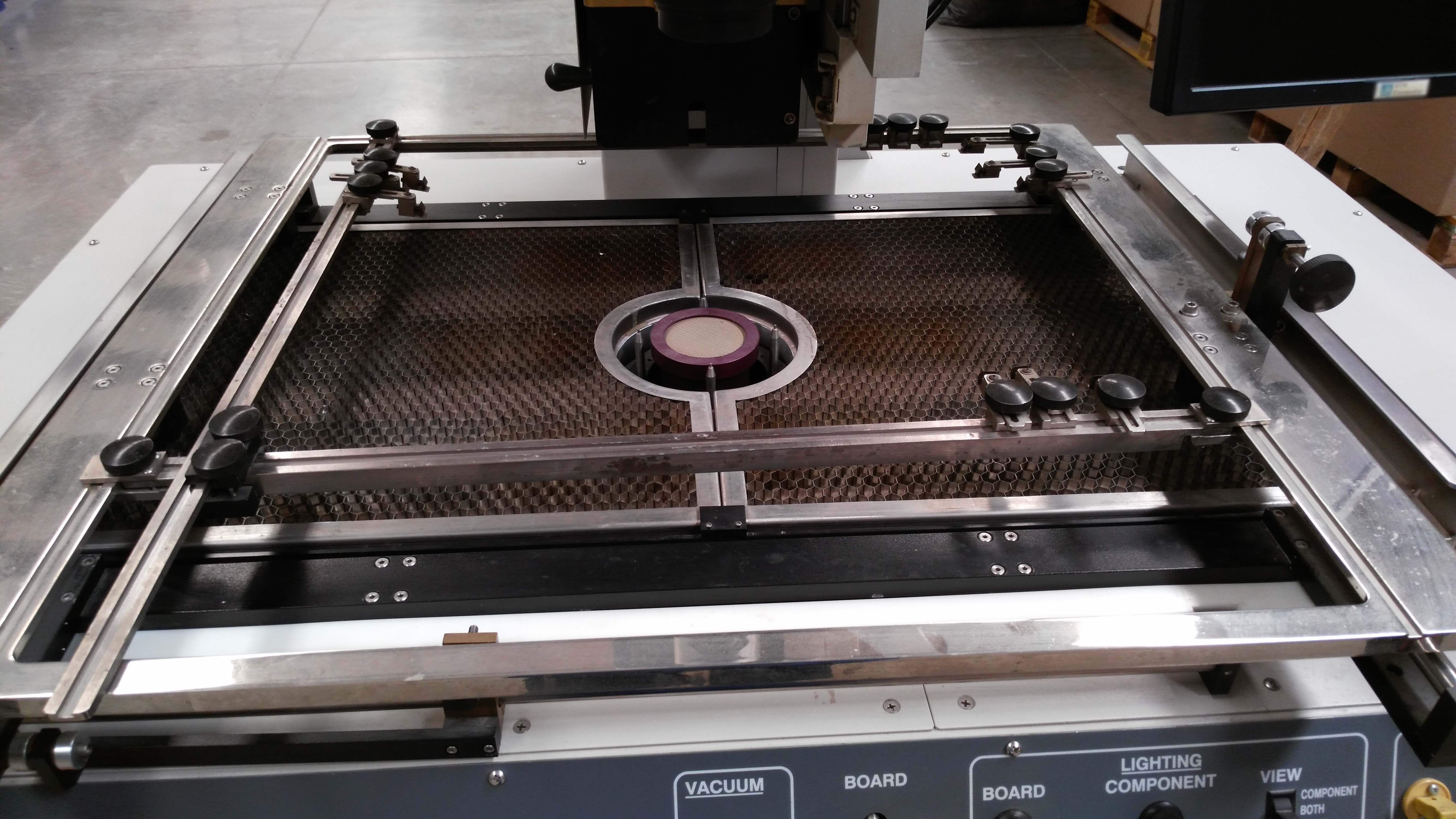

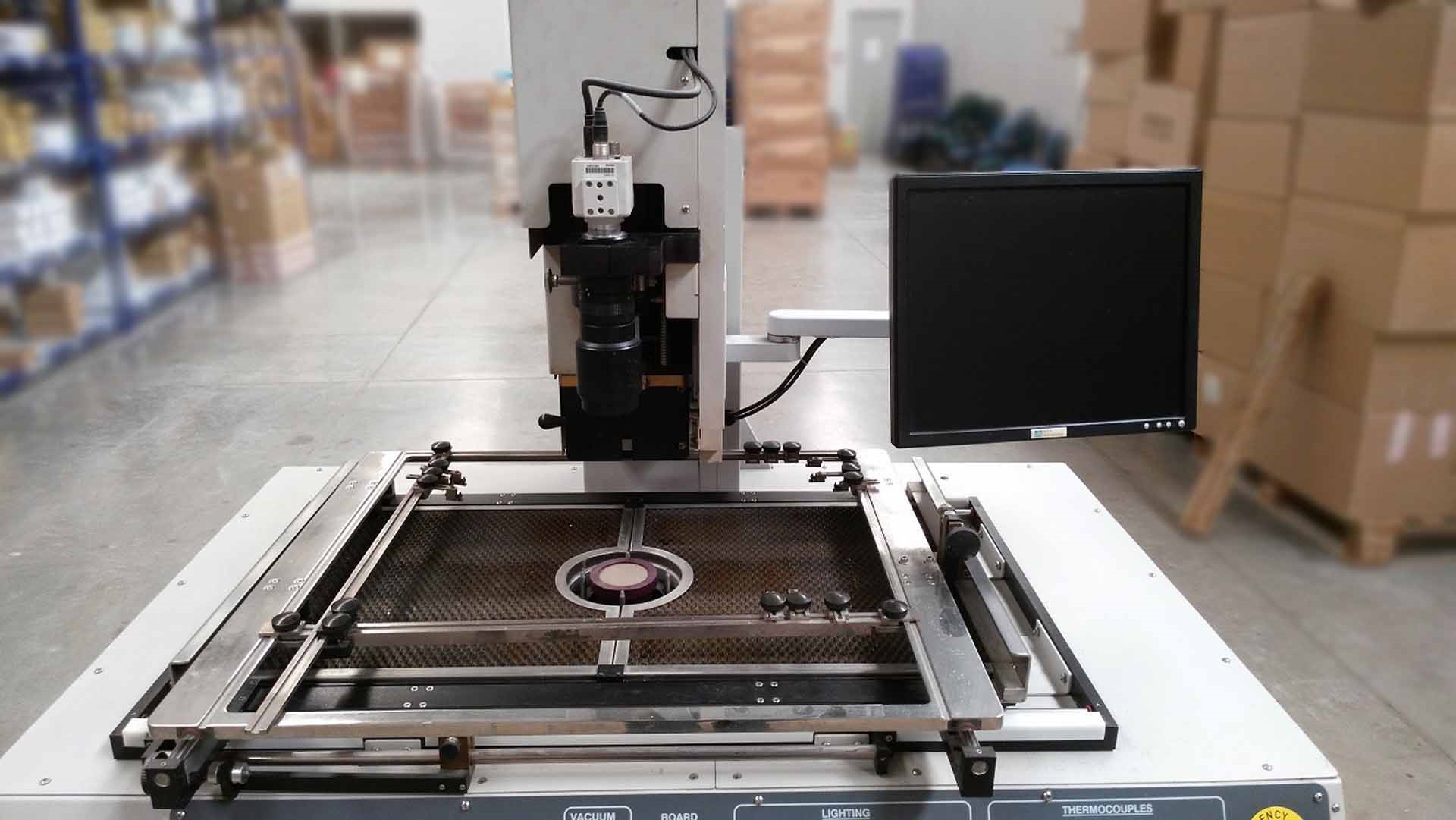

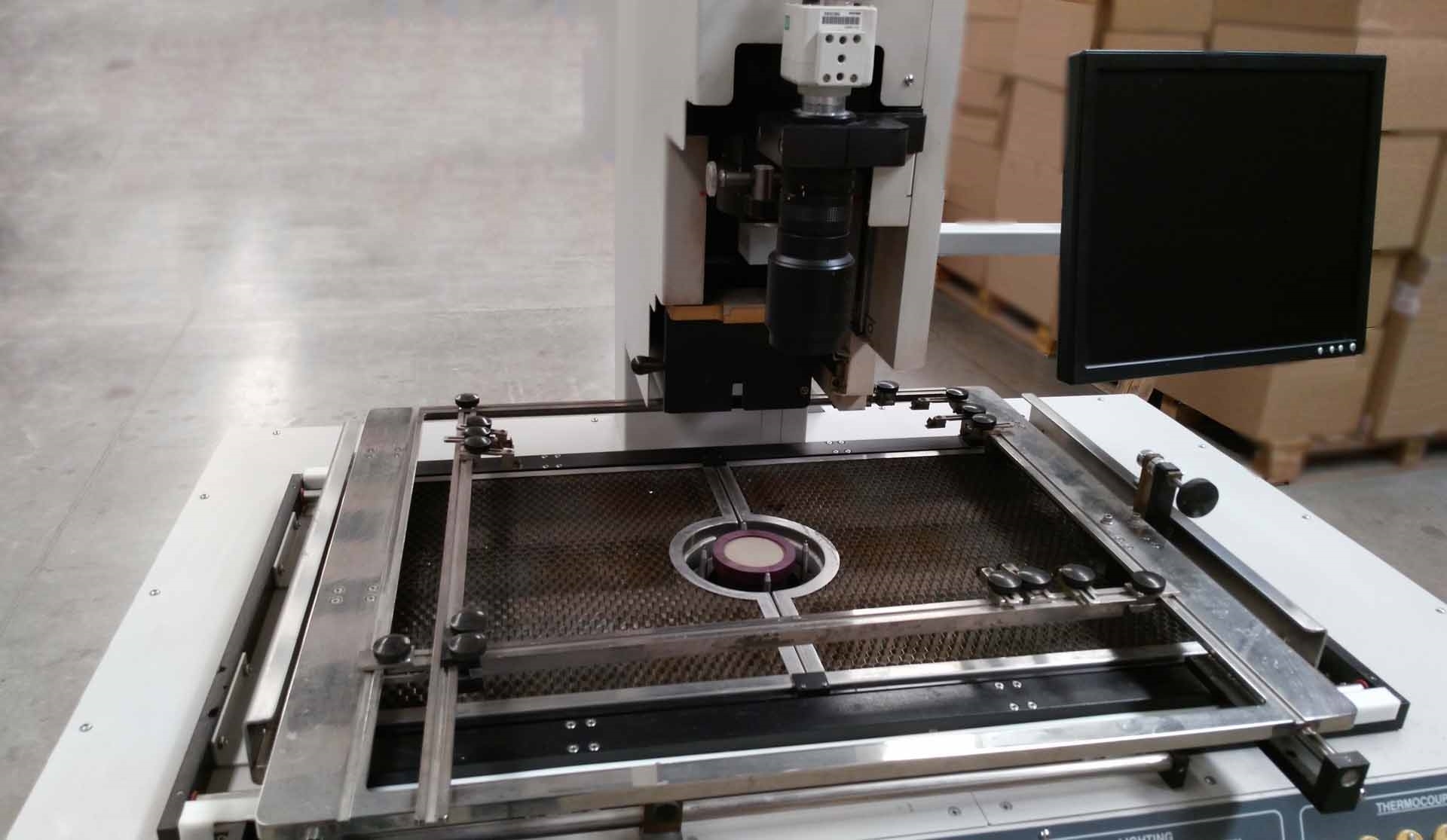

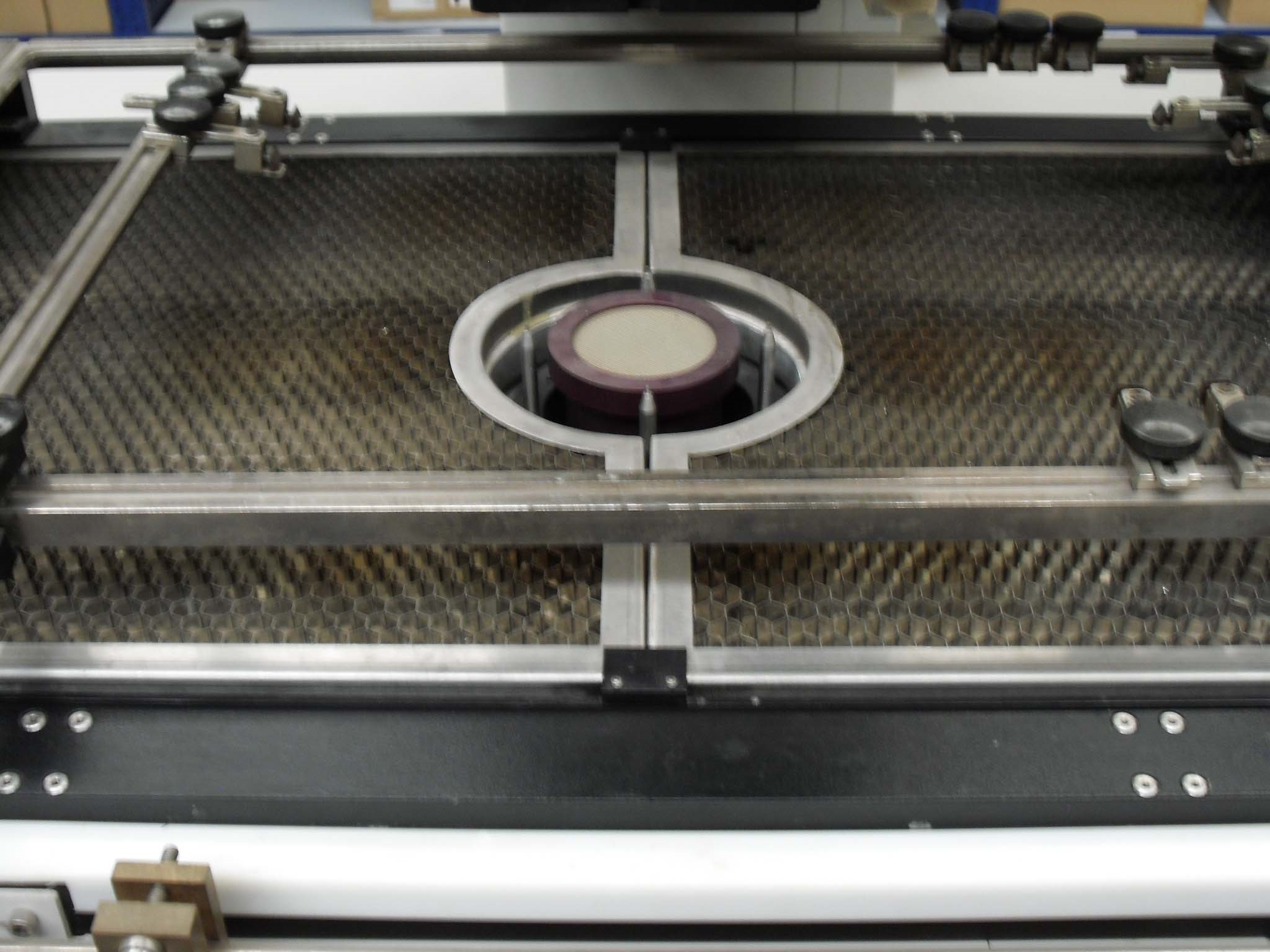

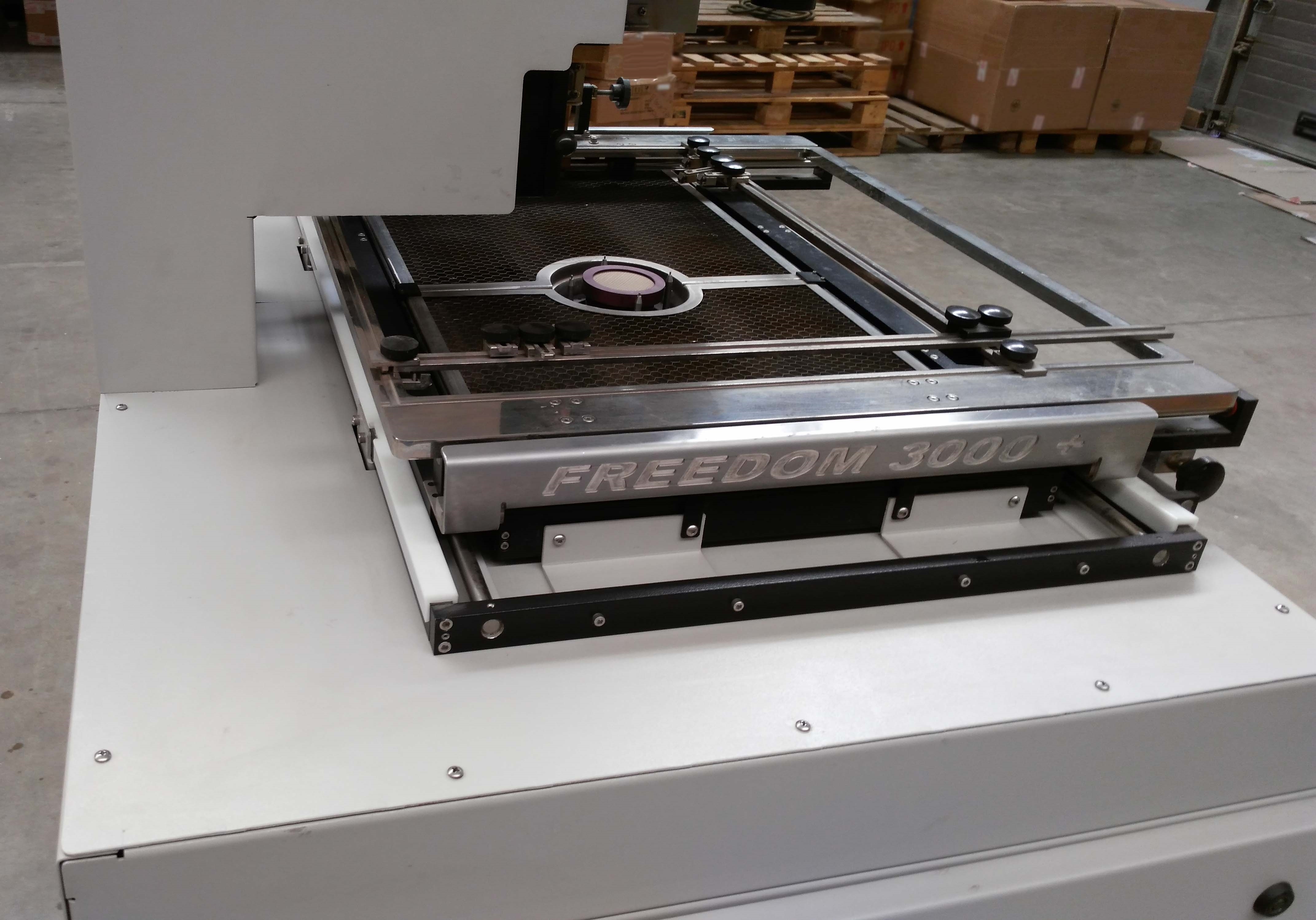

Used CONCEPTRONIC Freedom 3000 Plus #9074565 for sale

URL successfully copied!

Tap to zoom

ID: 9074565

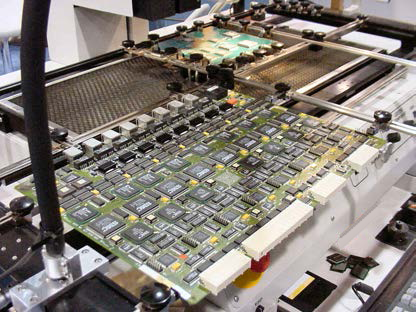

BGA Rework station

With accessories

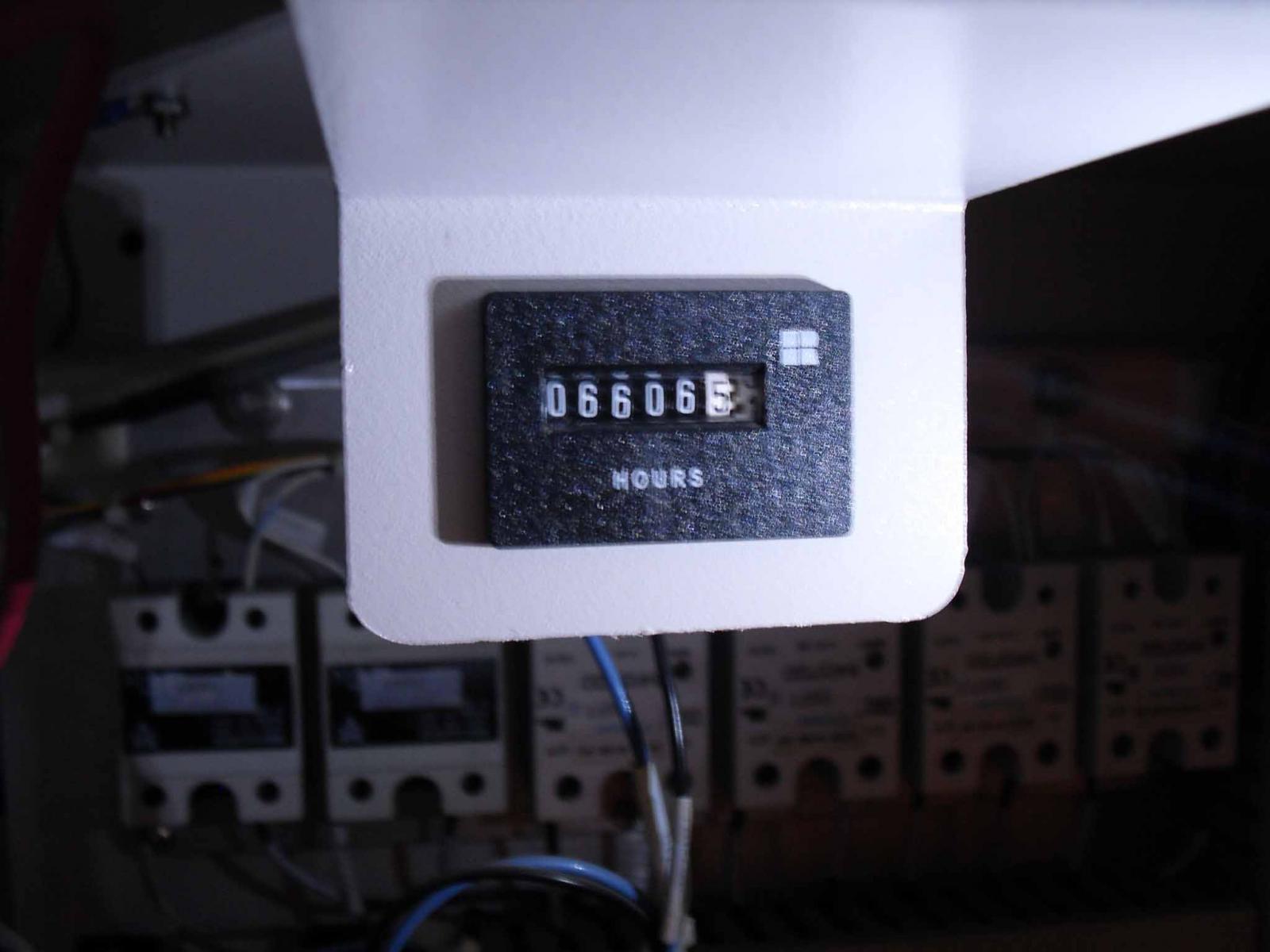

Running hours: 6,600

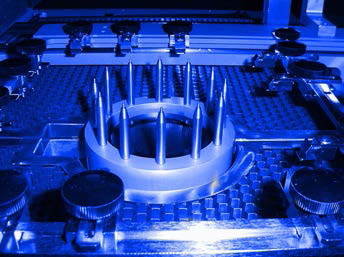

Nozzles

Heads

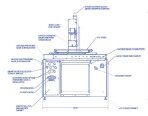

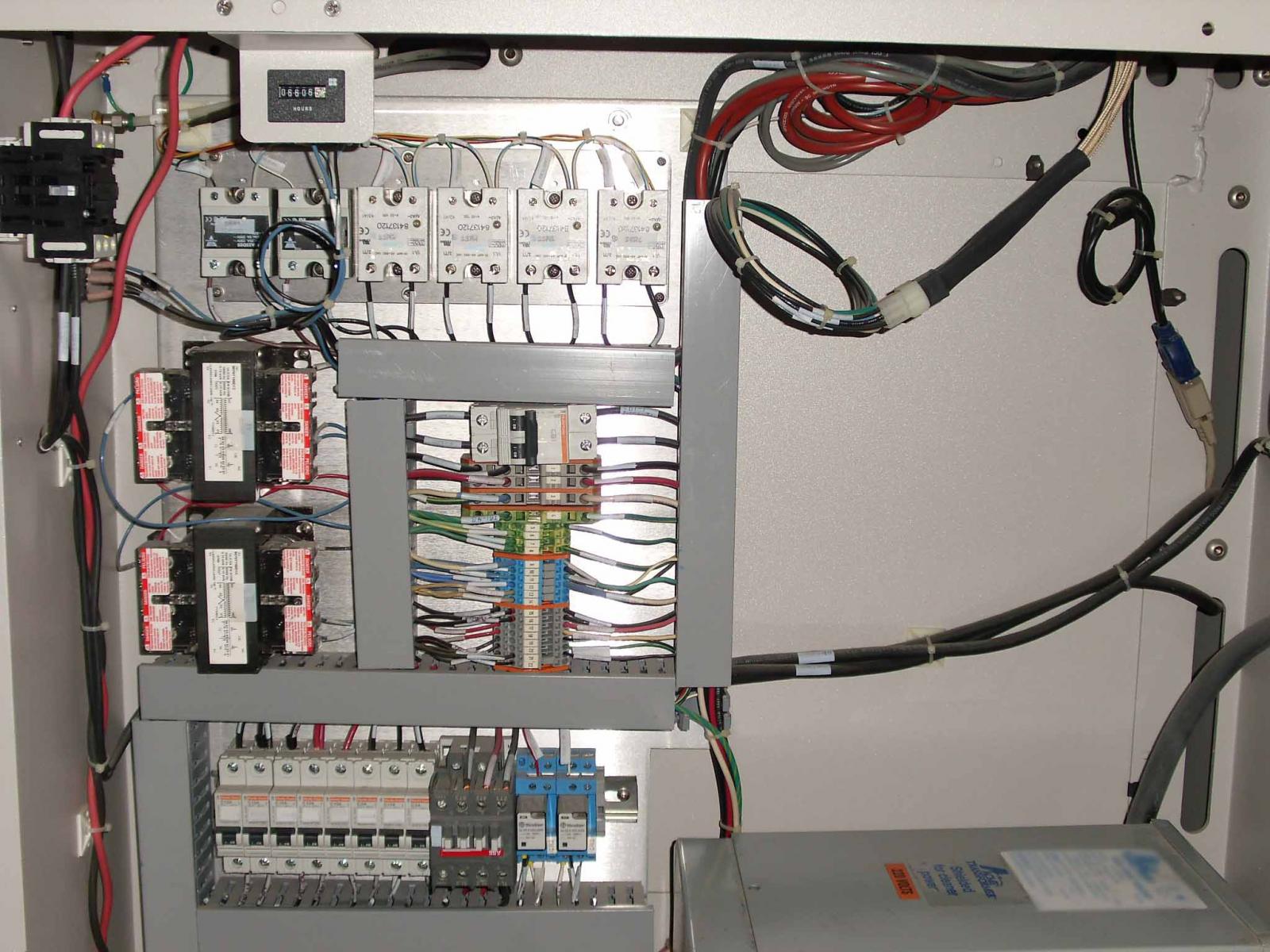

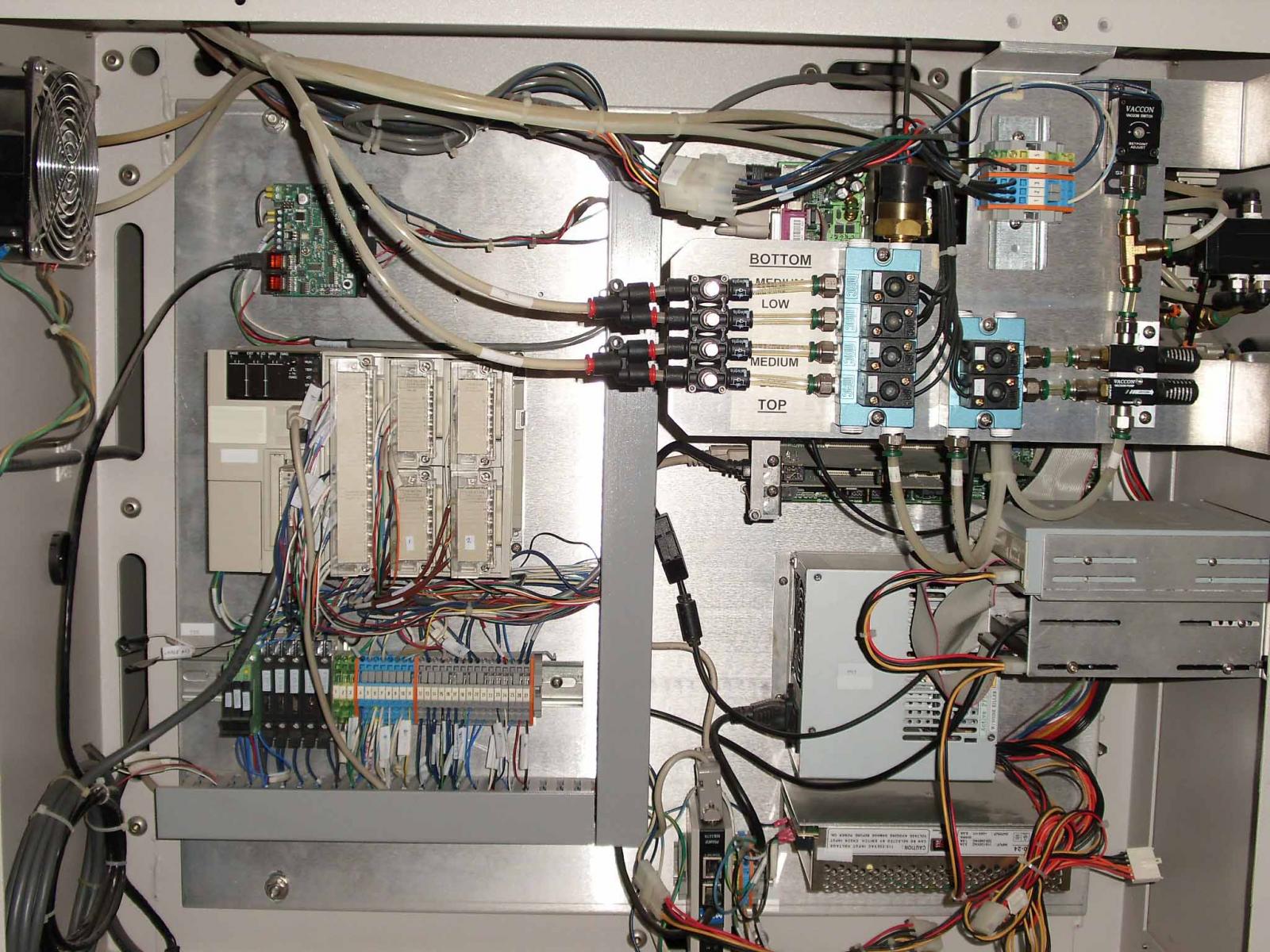

Control system:

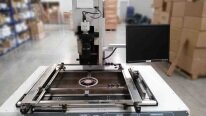

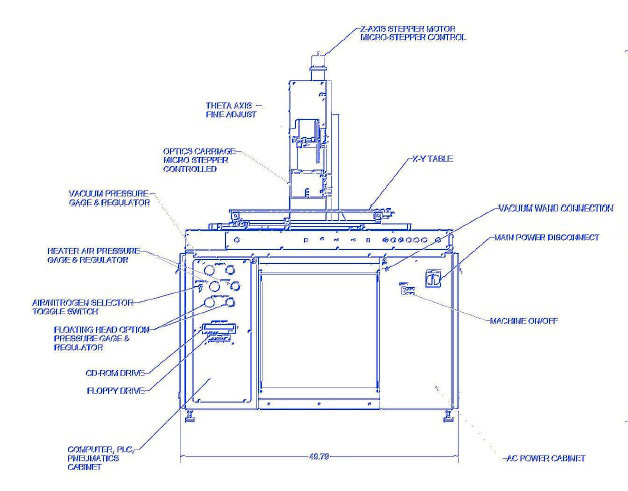

INTEL Pentium TM based PC

Hard Disc Drive (HDD)

Floppy disk drive, 3.5"

CD ROM Drive

Industrial-duty programmable logic controller (PLC)

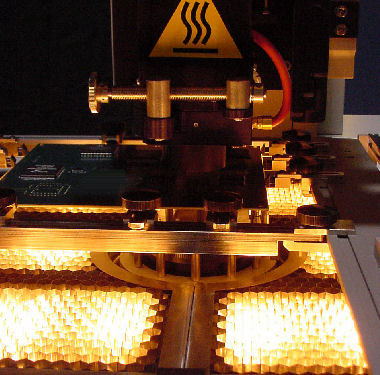

Real-time PID control: Forced

Convection hot gas heaters

Keyboard

Mouse

LCD Monitor, 15"

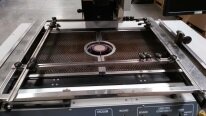

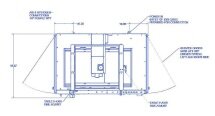

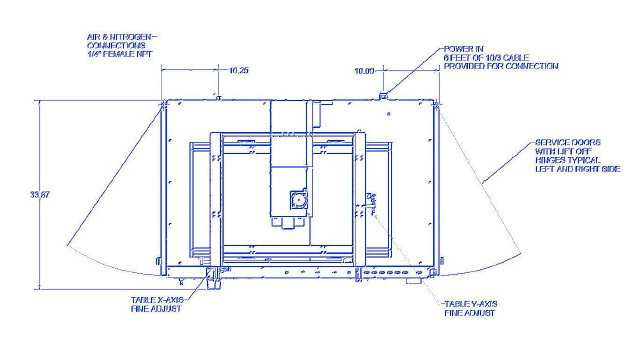

Board handling capacity:

Compact size: 14" x 14"

Standard size: 20" x 20"

Large board: 24" x 36"

Minimum size: 2" x 2"

Maximum size: 20" x 20"

PCB Thickness: Up to 0.25"

Component handling capacity:

Minimum size: 1 x 2 mm

Maximum size: 80 mm Quare

Handles both grid array and leaded type components (BGA, CGA, QFP, LCC, TSOP, FLIP-CHIP)

Placement accuracy: 0.001"

Able to repair boards with: Up to 2.4" tall components

Options:

Split mirror

Auto shuttle with calibrated positioning: Component pickup

Closed loop pressure sensing Z-axis control

Rotating nozzle: 360°

Factory calibrated optics

Fixed mirror

6 Thermocouple input ports: Real-time process monitoring and development

Precision bearings: Optics (Z-axis and X-Y table)

PCB Positioning table with X-axis and Y-axis

Breakaway heater head with builtin theta adjustment

Gas flow settings high, medium and low: Top and bottom process heaters

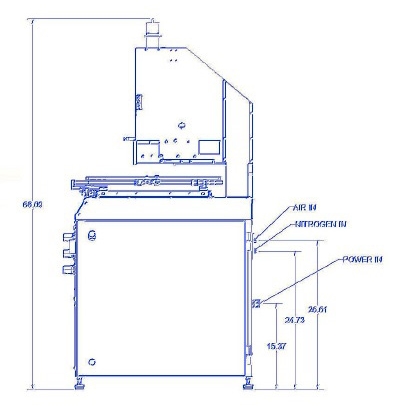

Heater operation: Air / Nitrogen

Vacuum pump and vacuum wand

Universal board holding fixture

Vacuum part pick up sensing switch

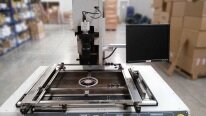

Color vision system

Camera

Lens

Frame grabber card

Manual optics train control: Rapid cycle times

Wide-array adjustable under board.

CONCEPTRONIC Freedom 3000 Plus is a complete pc board assembly and manufacturing equipment designed to provide efficient and reliable manufacturing solutions for various production lines. It is a compact and efficient assembly system, featuring a range of advanced technologies that make it ideal for low- to medium-volume production of high-quality electronic components. Freedom 3000 Plus is specifically designed to increase output and reduce waste through its set of applications. The unit includes a unique 4-axis robotic pick and place, four component feeders, quick-change nozzle, and routing capabilities. The robotic pick and place machine can quickly and accurately place 70+ components per second with an accuracy rate of up to 0.45mm. It also ensures maximum component preservation with precision loading and unloading techniques. CONCEPTRONIC Freedom 3000 Plus also includes four component feeders which deliver parts accurately and reliably during assembly. The tool also features quick change nozzle solutions, allowing for a no-tool changeover from the standard 6mm to 8mm nozzle size. This ensures maximum efficiency during production and reduces downtime for nozzle resizing. The routing capabilities of Freedom 3000 Plus asset are also remarkable. It provides efficient routing of up to 11 tracks per side on standard panel sizes, with potential reductions in material and cycle times. The model also features an on-the-fly change in process parameters, allowing quick and easy setup for quick changeover and production. In addition, CONCEPTRONIC Freedom 3000 Plus equipment also features an easy to use interface with an intuitive graphical interface for quick programing and setup. This makes it easy even for inexperienced operators, while providing convenience for experienced operators. Overall, Freedom 3000 Plus is an advanced and efficient assembly and manufacturing system. Its robust design, versatile components, and intuitive interface ensure efficient and reliable production of high-quality circuitry. With its advanced features and capabilities, this unit provides a unique solution for various electronics production lines.

There are no reviews yet