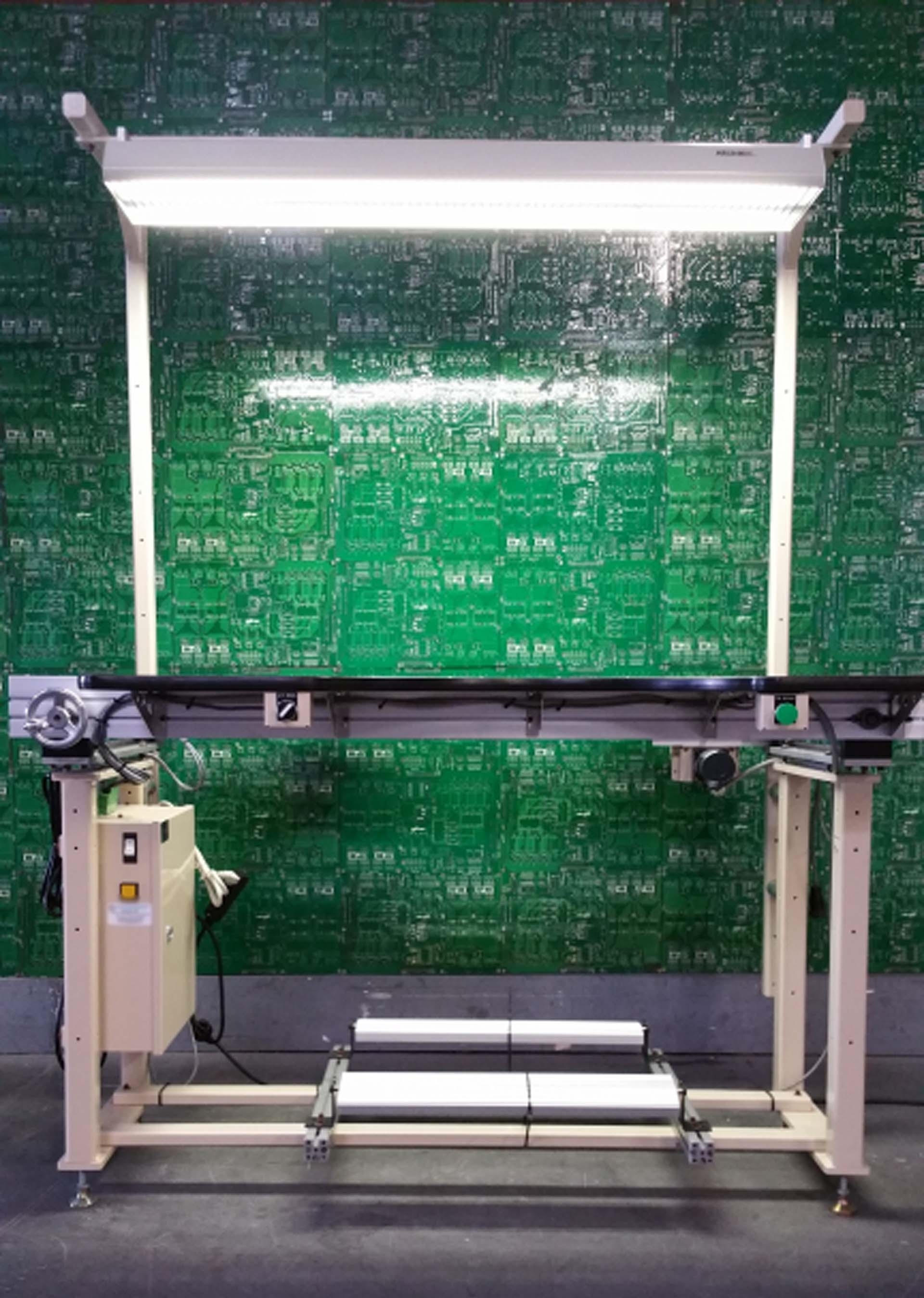

Used CONVEYOR TECHNOLOGIES / CTI XCW-1.5M-1-2/2 #9228225 for sale

URL successfully copied!

Tap to zoom

ID: 9228225

Vintage: 2004

Machine

1.5 Meter workstation conveyor / Dual sided

Board width, 18"

One section conveyor

Overhead light - foot rest

Overhead light is not assembled

2004 vintage.

CTI XCW-1.5M-1-2/2 is a pc board assembly and manufacturing equipment designed to help companies save time and money in the production of printed circuit boards (PCBs). It is a highly automated system that takes routed pc board panels and feeds them through a series of robotic processes to mount electronic components, test boards, and bond wires. CONVEYOR TECHNOLOGIES XCW-1.5M-1-2/2 features a CNC-controlled gantry, which allows for adjustable speeds and velocities to optimize speed and accuracy while routing panels. The unit also functions as a pick and place machine, which facilitates the accurate placement of components onto the boards. This tool also boasts a high-speed component inspection asset, which is designed to quickly check components for proper alignment and polarity. CONVEYOR TECHNOLOGIES / CTI XCW-1.5M-1-2/2 is equipped with a reflow module that is capable of accommodating different sizes of substrate and panel materials. This model can heat the assembly quickly and evenly to desired temperatures, enabling the solder balls to form on each component at the correct locations. This module also allows for a moveable PCB support table, which ensures that individual components are not damaged or pressed too hard onto the board. In addition, CTI XCW-1.5M-1-2/2 also includes a test station, which is designed to check for acceptable electrical and functional continuity between various components. This equipment features a self-calibration protocol, which enhances the accuracy of its testing processes. Additionally, the machine is equipped with an advanced wire bonding system that makes it easy to bond wires between various parts on the board. Overall, CONVEYOR TECHNOLOGIES XCW-1.5M-1-2/2 is an efficient and reliable pc board assembly and manufacturing unit. It is fully automated and offers a range of features to improve production speed and accuracy without compromising quality. The machine can be effectively used to produce a wide variety of pc board applications, making it a great option for various industries.

There are no reviews yet