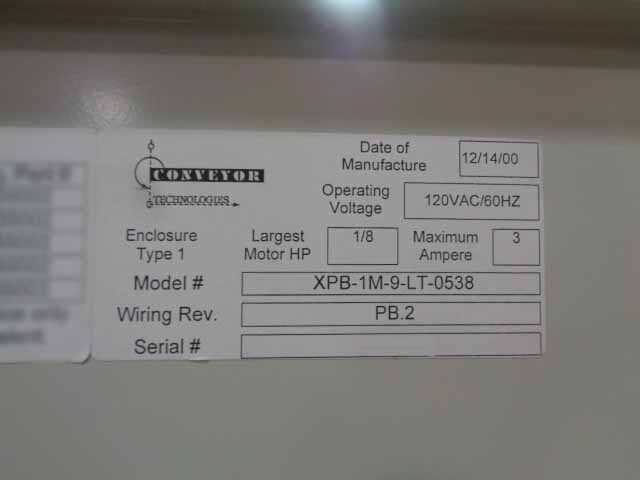

Used CONVEYOR TECHNOLOGIES / CTI XPB-1M-9-LT-0538 #9162600 for sale

URL successfully copied!

Tap to zoom

ID: 9162600

Vintage: 2000

FIFO / LIFO buffer

P/N: 160505

Volts: 120

Phase: Single

Amps: 3

Hertz: 60

Options:

FIFO 9 Section

Conveyor track length: 22.5"

Crank & mechanical width: Min: 1.75" Max: 17.75"

Omron Sysmac CQM1 PLC

2000 vintage.

CONVEYOR TECHNOLOGIES / CTI XPB-1M-9-LT-0538 is a PC Board Assembly/Manufacturing equipment designed to provide cost-effective solutions to a variety of electronics manufacturing challenges. The system is an ideal choice for high-volume, automated production processes, combining advanced automation, product flexibility, and affordability. CTI XPB-1M-9-LT-0538 consists of four major components: the conveyor unit, a robotized pick-and-place head, an integrated vision machine, and a 900 W hot-air reflow tool. The conveyor tool is designed for efficient handling and transport of PCB assemblies through the different stages of manufacturing. The asset includes variable-speed, variable-pressure, and zero-gap belt conveyors, along with a patented module-level motor control model that provides precise speed control, allowing CONVEYOR TECHNOLOGIES XPB-1M-9-LT-0538 to accommodate a wide range of PCB assemblies. The robotized pick-and-place head is mounted on a motorized lead screw sliding platform, providing an ergonomic design that reduces fatigue and increases production throughput. The robot head can accommodate 3"×7" PCBs, with a maximum component height of 9 mm. An integrated vision equipment assists the robot in accurately locating and placing components during assembly. The system also includes a 900 W hot-air reflow tool, which allows for precise temperature and air flow control for optimal PCB soldering. The hot-air reflow allows for a fast, repeatable, and reliable reflow process, ensuring consistent board level quality. In addition, the unit includes various safety features and controls, such as emergency stop switches, contact points, and tamper detectors. These safety features help reduce the risk of accidents and injuries in the production environment. XPB-1M-9-LT-0538 is an automated PC Board Assembly/Manufacturing machine that provides efficient production and cost-effective solutions in the electronics manufacturing industry. The tool's advanced automation, product flexibility, and affordability makes it an ideal choice for high-volume production processes.

There are no reviews yet