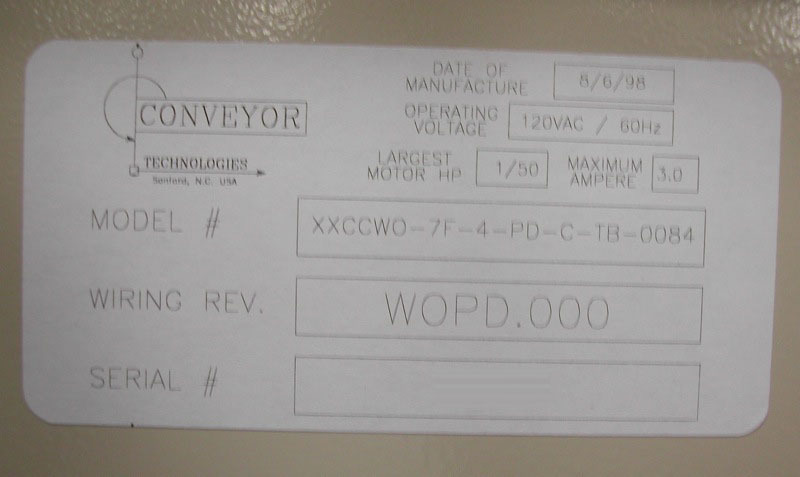

Used CONVEYOR TECHNOLOGIES / CTI XXCCWO-7F-4-PD-C-TB-0084 #9009774 for sale

URL successfully copied!

Tap to zoom

ID: 9009774

Vintage: 1998

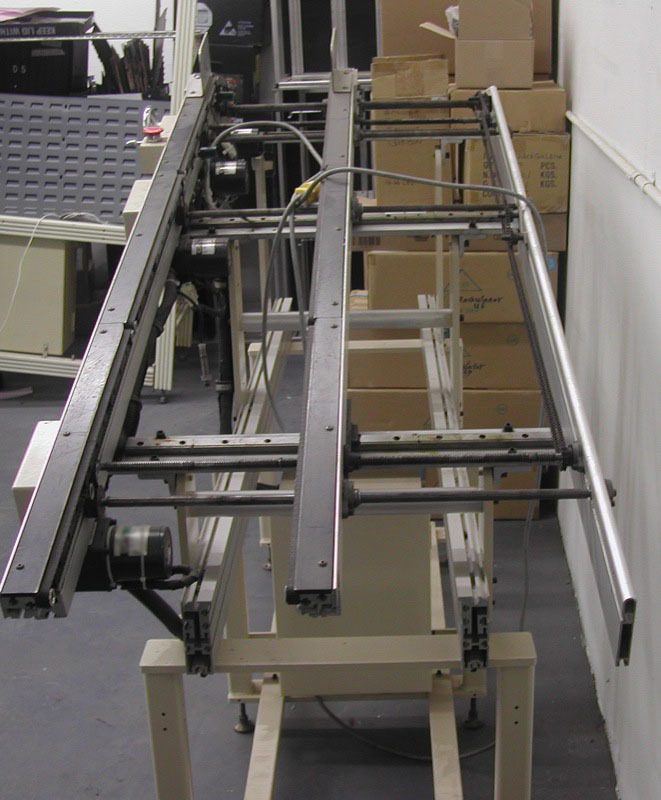

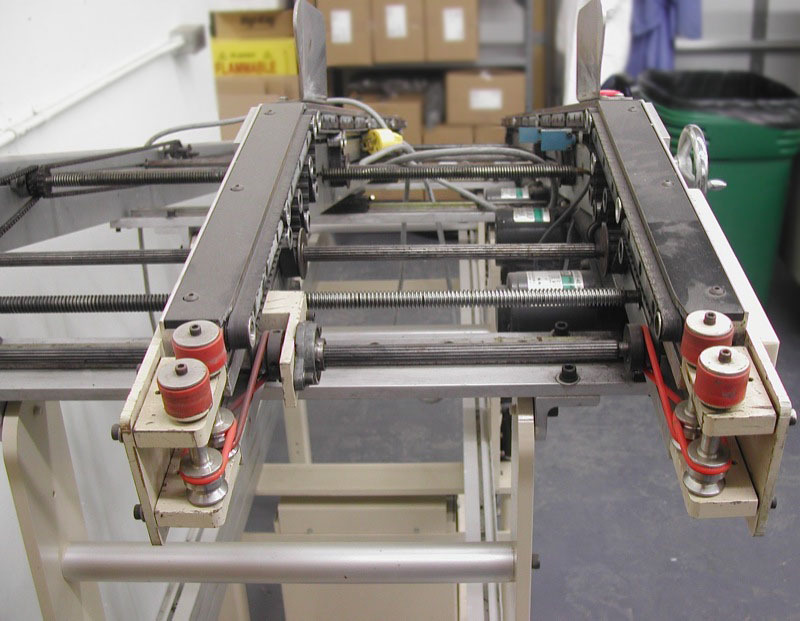

Wave unloader conveyor

Largest motor HP: 1/50

Max ampere: 3.0

120 VAC, 60 Hz

1998 vintage.

CONVEYOR TECHNOLOGIES / CTI XXCCWO-7F-4-PD-C-TB-0084 is a turnkey conveyorized assembly and manufacturing equipment designed for small to medium-sized production runs. The system is composed of several components, including Infeed conveying loaded pallets and stacking support frames, a rotary indexer, 2 vertical assembly lines, two 7-axis robotic welding cells, and an Outfeed conveyor with discharge pallet for completed assemblies. The Infeed conveyor line is designed to accept fully loaded pallets and stacking support frames moving along at a variable speed from 5 to 60 meters / min. The conveying line is equipped with a multi-position robotic gantry and multiple workstations along its length for performing machining operations, such as drilling and tapping, as well as automatic welding and assembly operations. The Infeed conveyor can be easily programmed with desired pallet/frame changes and automations, providing a fast and efficient parts handling solution for any small to medium-sized production run. The unit also includes a rotary indexer which is used to feed the components of the structured assembly line, following a specific sequence. The indexer is controlled by a user-friendly HMI machine that can be configured to move parts in up to four universal, fixed, or custom orientations. Two vertical assembly lines with variable speed of up to 60 meter/min are used for assembly operations. Each line consists of several manipulator heads, which can be programmed for various controlled motion sequences. The heads can also be armed with automatic welding torches and grinders, as well as semi-manual tools such as rivet guns and screwdrivers, for additional handling operations. The assembly lines can be adjusted between 10-90 cm for different parts sizes and configurations. The two 7-axis robotic welding cells are designed to provide the highest quality welds while minimising operator risk. Each cell is equipped with two robotic arms, which are pre-programmed to perform automated welding and cutting processes, plus a power supply unit, gas mixers and other accessories. The cells are also fitted with several safety sensors and systems for guaranteed safety and compliance with all manufacturing regulations. The Outfeed conveyor is designed to move completed assemblies away from the assembly lines as needed. It is a palletized conveyor line with an adjustable speed range from 10 to 60 meters / min and a discharge area for completed assemblies. Overall, CTI XXCCWO-7F-4-PD-C-TB-0084 is a reliable and efficient tool for producing a variety of small- and medium-sized machined components and assemblies. The asset is capable of performing many of the usual operations like drilling, tapping, welding, and assembly, and is designed for maximum flexibility and safety in all manufacturing environments.

There are no reviews yet