Used CYBEROPTICS SE 200 #10758 for sale

URL successfully copied!

Tap to zoom

ID: 10758

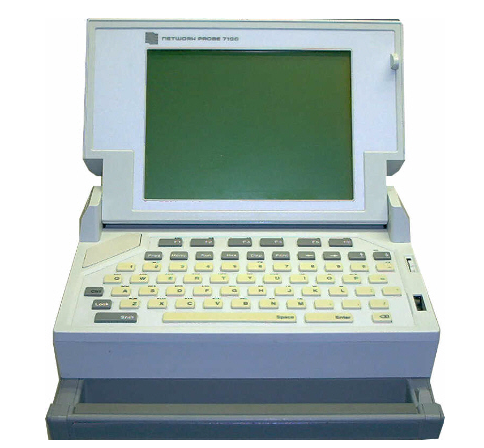

Inline Solder Paste Inspection System

Windows NT operating system and Intel Pentium III processor

Collects data on paste height, area and volume

Uses standard SMEMA communications

Accepts barcode reader input

Includes:

Scanning sensor head mounted on automated, programmable robot

High-performance Ethernet card, network port and two serial ports

Iomega Zip drive, disk drive and CD-ROM drive

9 gigabyte Ultra-wide SCSI hard drive

Programmable warning light tower

15-inch color monitor

Industrial-grade trackball

Conveyor alignment panel

Solder paste repeatability: 2 microns (0.08 mil) @ 1 sigma

NIST-traceable standard

Repeatability: 1 micron (0.04 mil) @ 1 sigma

Accuracy: 5 microns (0.20 mil)

Maximum board size (configuration dependent): 460x560mm (18x22 in)

Maximum field of view: 9.0x6.7mm (350x265 mils)

Depth of field: ±2mm (79 mils)

Typical inspection speed: 0.75 seconds

System controller: Pentium III processor

Power requirements: 100-120/220-240 volts, 50/60 Hz, 6/3 amps

Compressed air (for board stopper) 580-825 kPa (80-120 psi).

CYBEROPTICS SE 200 is a fully automated PC board assembly and manufacturing equipment. It uses advanced vision data capture and software to accurately and quickly put together boards for PC assembly and manufacturing. The system is easy to program and allows for precise and efficient controls over the entire production process. The unit is equipped with several advanced vision capabilities, such as soldering, printing, inspection, and deposition. It also consists of a machine company for cutting, drilling, and all other necessary operations. The machine is made with a speed of up to 9,000 components per hour and has a precision rate of up to 0.065mm. It also provides enhanced reporting, traceability, and tracking capabilities. CYBEROPTICS SE200 uses a number of components and features, which makes it an ideal option for manufacturers. These features include automated printer management, data collection, placement verification, surface mounting, and more. Additionally, it has the ability to process a wide range of components, such as flip-chips, BGA, ultra-lone-pitch, lead-free solder, and more. When it comes to the inspection process, SE 200 is equipped with a four-sided vision tool that provides precision accuracy and enhanced traceability. With this asset, the machine can detect surface mount defects, such as shorts, opens, bridging, tombstoning, etc. It also provides real-time process tracking and SPC data collection, which help ensure quality control. The model also includes a three-axis linear drive robotic arm for placing components. With its advanced controls and high accuracy rating, this arm ensures maximum accuracy and reliability. Additionally, the equipment can be integrated with other factory automation systems, such as automated storage and retrieval systems, for more efficient production throughput. Overall, SE200 is an advanced PC board assembly and manufacturing system that provides high-speed and high-accuracy processing of components. Its advanced vision unit and robot arms provide traceability and precision, while its advanced printing and machine industry capabilities ensure optimal quality and efficiency.

There are no reviews yet