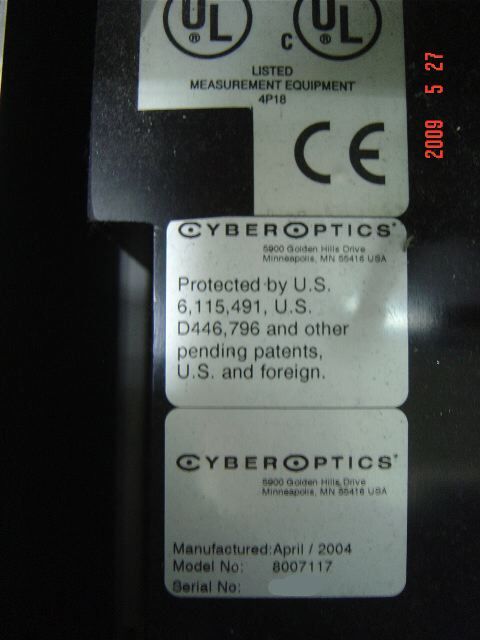

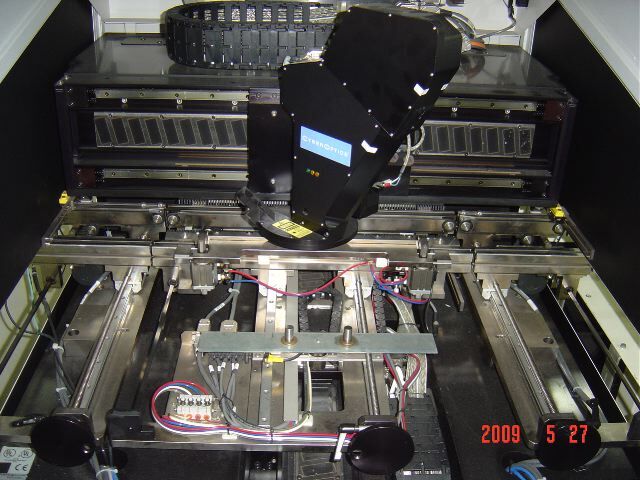

Used CYBEROPTICS SE 300 #74229 for sale

URL successfully copied!

Tap to zoom

CYBEROPTICS SE 300 is an advanced, PC-driven board assembly and manufacturing equipment. It is used to create components for advanced electronics, medical, automotive, and communications systems. It has a wide range of capabilities and is able to perform a variety of tasks, including surface mount printing, component placement, component test and repair, board inspection and testing, board programming, and pre-jump soldering. The system is equipped with an advanced vision unit, allowing it to accurately inspect and place components. It performs two-dimensional and three-dimensional inspections in order to detect missing or misaligned components. The vision machine also provides part guidance for component placement, which helps to ensure accurate assembly for even the most complex boards. The tool includes multiple heads for different processes: a printing head for surface mount printing, up to four placement heads for component placement, a head for optical inspection, and a heating head for soldering. It is also capable of performing multiple process steps simultaneously, making it extremely productive. In addition, the asset can be easily connected to other equipment, such as placement and soldering robots, to create a fully automated assembly line. SE 300 includes a variety of powerful software tools to support its operations. This includes a CAD-compatible software package, which allows it to be connected to any CAD model or database. It also features a library of parts, which helps to optimize processes based on the data stored in each part's description. In addition, the equipment is equipped with tools to automate the checking of components after they are placed onto the board, allowing for quick diagnosis and repair of errors. Overall, CYBEROPTICS SE 300 is an advanced and powerful PC-driven board assembly and manufacturing system designed to increase the efficiency and accuracy of board assembly. Its advanced vision unit and powerful software tools allow it to quickly and accurately inspect, place, and solder components onto boards, making it the ideal machine for companies looking for the highest levels of board assembly and manufacturing quality.

There are no reviews yet