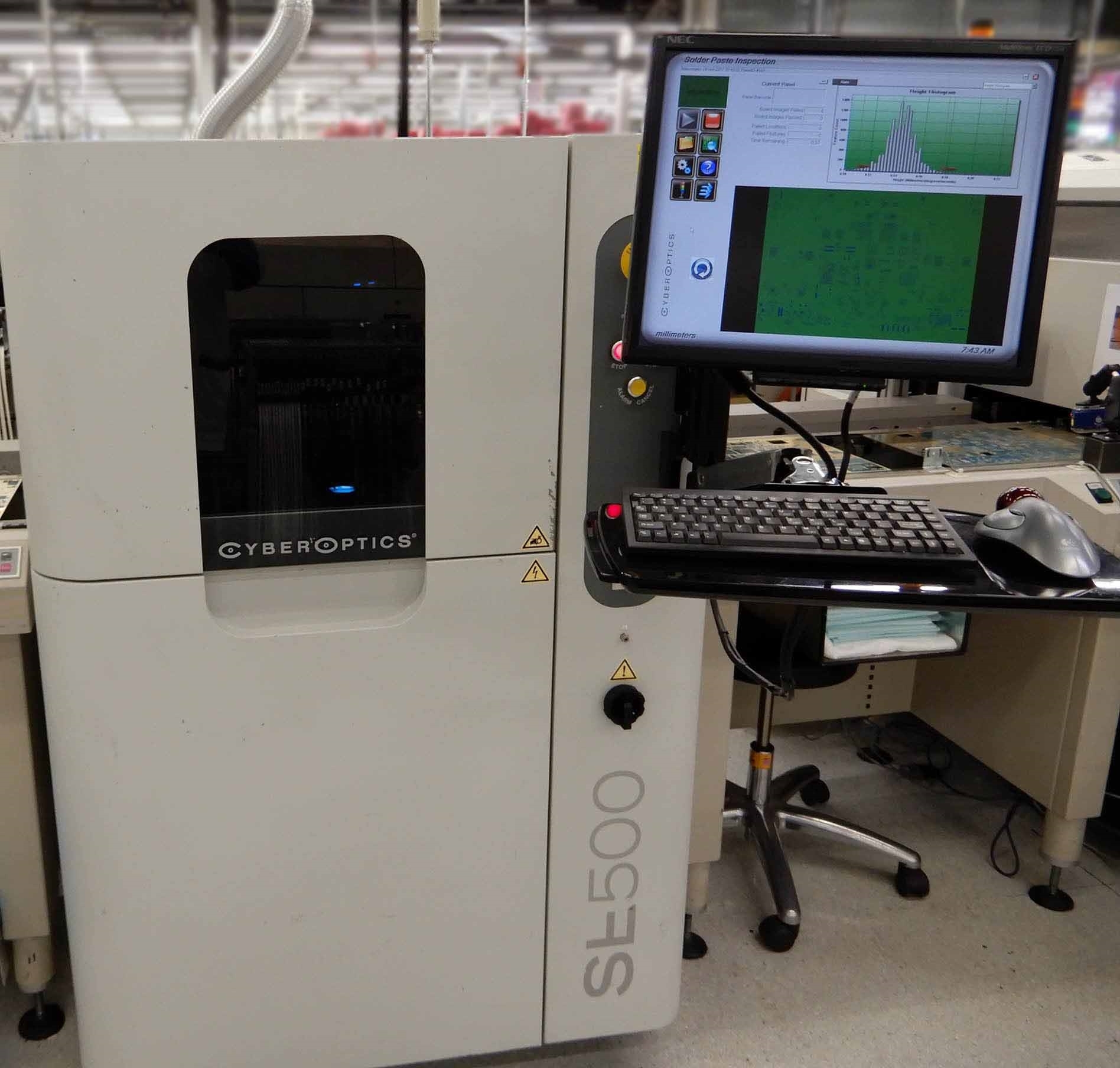

Used CYBEROPTICS SE 500 #9184067 for sale

URL successfully copied!

Tap to zoom

ID: 9184067

Vintage: 2011

Solder Paste Inspection (SPI) systems

Barcode reader: MATRIX 200

PC

No dual monitor kit

No dual illumination upgrade kit

Panel size capacity:

Maximum: 510 x 510 mm (20 x 20)

Minimum: 50 x 50 mm (2 x 2)

Board thickness:

0.3 to 5.0 mm (0.01 to 0.2)

0.5 to 6.0 mm (0.02 to 0.24)

Board edge clearance:

Top: 2.5 mm (0.10)

Bottom: 3 mm (0.12)

Component clearance:

Topside (Above belt): 20.1 mm (0.78)

Bottom side: 25.4 mm (1.0)

Maximum board weight:

SE500 3 kg (6.6 lbs) 5 kg Option

SE500-X: 10 kg (22 Ibs)

Maximum board warp: < 2%

PCB Diagonal / Maximum: 6.35 mm (0.25)

Operational specifications:

Conveyor speed range: 150-450 mm/sec (5.9-17.7 in 7sec)

Maximum inspection area: 508 x 503 mm (20 x 19.5)

Maximum pad size in FOV: 15 x 15 mm (0.6 x 0.6)

X/Y Pixel size:

High speed: 30 pm (1.2 Mils)

High resolution: 15 pm (0.6 Mils)

Operating system: Windows XP

2011-2013 vintage.

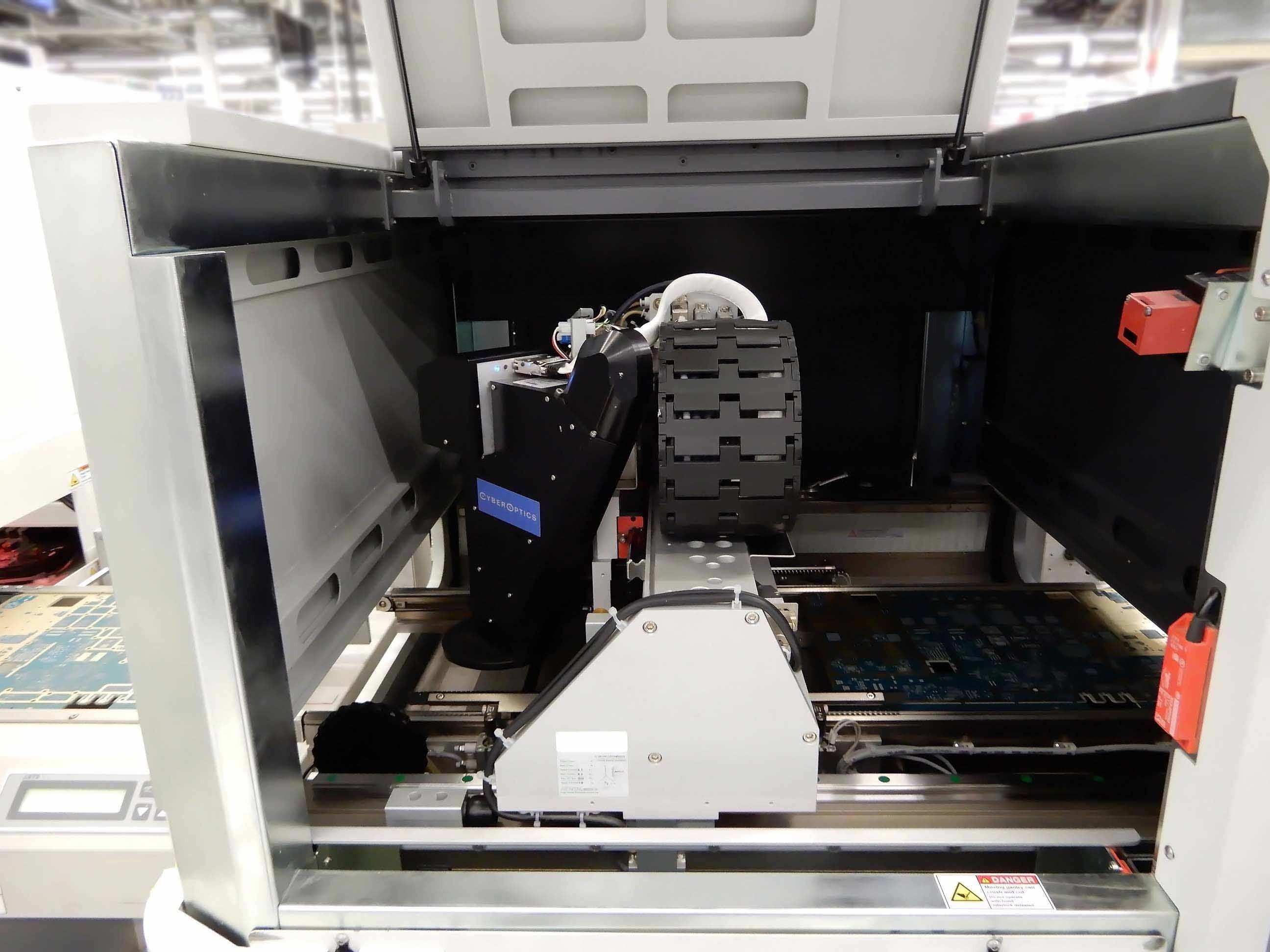

CYBEROPTICS SE 500 is a PC board assembly and manufacturing equipment designed for small to medium-scale production runs. It is capable of performing complex and demanding processes such as component and solder paste placement, conformal coating, fluxing, soldering, and inspection for a variety of PC board assemblies of up to 2.5m in length and width. CYBEROPTICS SE500 is designed with expertise in thermal management and innovative upgrades to power design. It is equipped with a three-camera alignment system for enhanced accuracy of part placement. It also includes an ultra-high resolution, array-based laser subsystem for accurate laser imaging, inspection, verification, and feedback to the computer. Furthermore, it features an automated component cleaning unit for improved reliability and reliability during production runs. SE 500 is designed with an intuitive graphical user interface with easy to use software, which allows for quickly programming production runs and significantly improves productivity. The unit has an extensive library of pre-defined parameters to meet the requirements for a variety of onboard assemblies and components. This library includes parameters for component placement, area detection, solder paste type, volume and soldering temperature settings. SE500 has full diagnostic capabilities and feedback with intelligent alarms and setpoints for checking operations status during production runs, and a powerful predictive maintenance mode to prevent potential issues before they occur. Additionally, the machine has an extensive safety protocol in place to control any hazardous or potentially hazardous conditions; this includes protective shutters and powerful safety alarms. CYBEROPTICS SE 500 also features an embedded version of CYBEROPTICS award-winning SPC™ technology, giving users the tools to analyze data from each production run and improve the quality and productivity of their production lines. Finally, its compact design, low cost of ownership, and high availability make it one of the most cost-effective PC board assembly and manufacturing systems on the market today.

There are no reviews yet