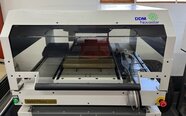

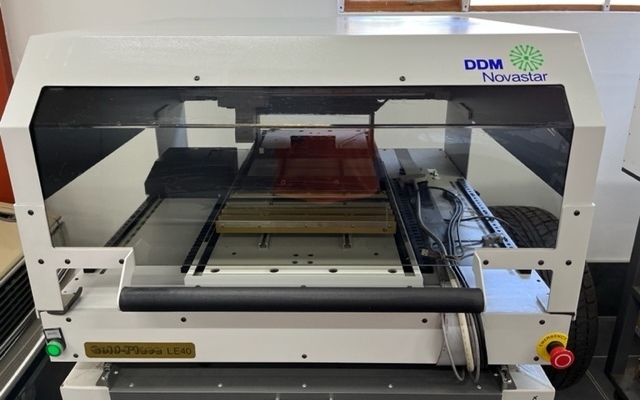

Used DDM NOVASTAR LE-40V #9248066 for sale

URL successfully copied!

Tap to zoom

ID: 9248066

Vintage: 2012

Pick and place machine

Vision centering: Top and bottom cameras

Placement rate: Up to 3,000 cph

Graphical User Interface (GUI)

(56) Tape feeders

(84) Tape positions

(2) 12 Lane 8 mm bank feeders

Precision placement head with closed-loop logic

Track components with SMTrue smart feeders

Board size: 13.5" x 22"

Component capability: 0201 Components

Component size: 1.96" Square body

Placement accuracy: ±0.001" (0.025 mm)

Placement rate: 3000 cph

Placement rate: 1800 - 2500 cph

Fine pitch capability: 15 Mil pitch (0.381 mm)

Travel area: 22" (X-Axis) x 22" (Y-Axis)

Matrix tray feeders with board / Matrix tray holders

Dispenser option: Up to 10,000 dots/Hour

Vibratory feeders: Loose, tube, stick (Frequency and amplitude control)

Feeders:

Qty / Model / Size / Description

(15) / LTS / 8 mm / Smart feeder

(12) / LTS / 12 mm / Smart feeder

(8) / LTS / 16 mm / Smart feeder

(5) / LTS / 24 mm / Smart feeder

Tape feeders:

8 mm / Super strip feeder

12 mm / Super strip feeder

16 mm / Super strip feeder

24 mm / Super strip feeder

32 mm / Super strip feeder

44 mm / Super strip feeder

Includes:

LED

BGAs

Pitch QFPs: 15 mil

SMT Connectors

Cut tape

2012 vintage.

DDM NOVASTAR LE-40V is a pc board assembly and manufacturing equipment that offers users a wide range of flexibility in designing and producing printed circuit boards, or PCBs. Offering both through-hole and surface-mounted components, this system gives users the ability to build both single and double-sided PCBs quickly and reliably. It also offers a variety of functions that allow for advanced production, such as test fixture and jam detection. LE-40V is a powerful and efficient production solution that offers excellent performance and cost savings. DDM NOVASTAR LE-40V pc board assembly and manufacturing unit includes an advanced vision machine and an embedded controller for complete control over the production process. The advanced vision tool ensures precise placement of components on the board by identifying parts and directing the production process accordingly. It features an integrated optical digital microscope that enables users to accurately inspect individual components for quality assurance. It also features an automated test asset to ensure quality and accuracy of the PCBs. LE-40V also features an advanced control model that delivers smooth, efficient production cycles. This equipment incorporates a control touchscreen with a high-resolution graphical user interface for easy management of the production process. It is also compatible with CAD and PCB design software for easy integration of the design process into the production system. In addition, DDM NOVASTAR LE-40V also provides an array of feeders and customized components to ensure reliable and efficient production runs. It also features a high-speed propagation protocol which enables faster production times and increases overall efficiency. And with its flexible design, users can scale the unit up or down according to their needs. Overall, LE-40V offers users a powerful and efficient pc board assembly and manufacturing machine that offers superior performance and cost savings. With its advanced vision tool, embedded controller, test asset, and array of feeders and customized components, it provides users with a flexible and reliable solution for producing high quality and accurate PCBs.

There are no reviews yet