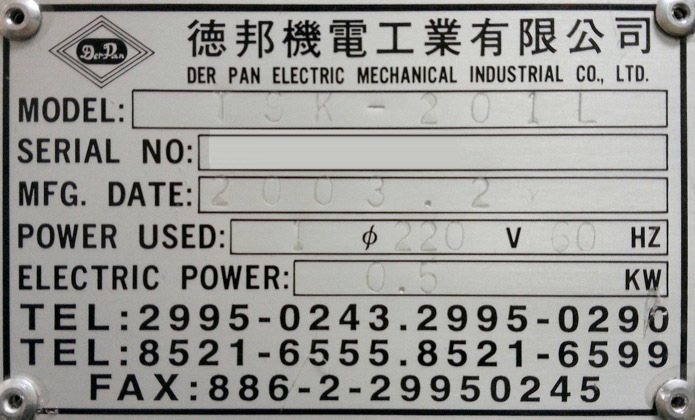

Used DER PAN TSK-201L #9049358 for sale

URL successfully copied!

Tap to zoom

ID: 9049358

Vintage: 2003

Unloader

Magazine track width: 320 mm

PCB board size: 60-250 mm (width), 350 mm (length)

2003 vintage.

DER PAN TSK-201L is a PC board assembly and manufacturing equipment for medium to high volume production. It is ideal for prototyping and short runs of precision PCB assemblies. TSK-201L has a maximum installed capacity of 768 boards, with the capability to produce small, medium, and large volume runs in the same batch. DER PAN TSK-201L offers several features that make it an ideal solution for prototyping and production. It has an intuitive user interface with real-time information display for fast and accurate assembly. The system uses linear servo-driven motors for increased accuracy and fast speeds. The integrated vision unit verifies component placement accuracy and inspects for any placement errors. This machine also offers automatic component insertion and pick-up with precision centering, soldering, and fluxing operations. The machine features a clean, safe work area with quick access and loading of boards. The mounting tool of TSK-201L ensures that all components are correctly seated and used per the specified parameters. Additionally, its intelligent SMT placement control asset ensures that all components are placed exactly where they should be with minimal waste. DER PAN TSK-201L offers a variety of options for more customized board assembly and manufacturing needs. It provides support for a wide range of component packages such as axial and radial through-hole and single- and dual-row SMT. Its multiple nozzle options provide for higher component placement rates and component bin sizes are adjustable to accommodate any component size. With its advanced connectivity options, this model has the capability to connect to external databases, allowing for real-time production data management. Overall, TSK-201L offers flexibility and speed for PCB assembly and manufacturing. Its features and capabilities make it an ideal solution for medium to high volume production runs and prototyping. Its intuitive user interface and real-time data display provides fast and accurate assembly, while its support for multiple component packages offers high performance and precision. Its connectivity to external databases allows for real-time production data management and improved production control.

There are no reviews yet