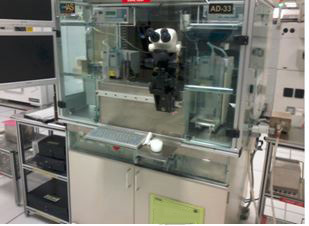

Used DIAS AUTOMATION AD33 #9131649 for sale

URL successfully copied!

Tap to zoom

DIAS AUTOMATION AD33 is a computer numerical control-based PC board assembly and manufacturing equipment, featuring high-precision electronics components placement and adhesive dispense for high quality board assembly and manufacturing results. The system is designed to provide ultra-accurate placement and dispense of the available components and features high-speed operation with repeatable accuracy. The unit features a user-friendly software control interface with easy programming in a number of languages including Teach, G-code and EDS. It also offers advanced settings for optimizing production output while ensuring product quality. The machine uses precision placement head which can place components on small boards up to 52 mm wide with repeatable accuracy. It also features adjustable spindle speeds that allow the tool to place components with a minimum of 0.2mm accuracy. The head is programmed to place ICs, connectors, SMSs, MODs and SMDs. With this head, the asset can also be used to assemble PCBs for wider applications. The model incorporates an embedded adhesive dispense unit for accurate and consistent adhesive dispensing. It uses dual-axis positioners and can accurately apply adhesives within ± 0.2mm. The dispense units can be programmed to release adhesives in pre-defined patterns or to spray adhesive in a single direction. In addition, the equipment offers a number of production features including probe detection, DREAM-O-Mat process tools, a data logger, active feeder, and remote operation. The probe detection feature allows the system to detect and immediately adjust for variation between boards such as variations in component position or component presence. The DREAM-O-Mat process tool is a patented technology developed by DIAS AUTOMATION. This tool allows for automated work processes and automatic optimization of the production process. The process tool also provides an intuitive unit monitor which helps users quickly identify any issues with the operation. The data logger is also available and allows users to save and analyze the production data for future use. The active feeder is integrated into the machine which controls the rate of moving components from the magazine to the pick-up head. Finally, the tool also includes a remote operation asset that allows the user to control the board assembly process from remote locations. Overall, AD33 is a highly automated and reliable PC board assembly and manufacturing model that provides quick and accurate placement and dispense of the available components while offering a range of features for optimization of production output. The equipment is suitable for a wide variety of applications and allows users to quickly and accurately assemble boards with a minimum of effort.

There are no reviews yet