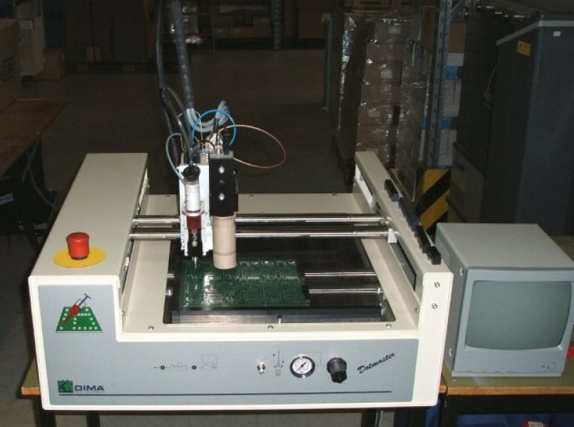

Used DIMA Dotmaster SMDU 5001 #137398 for sale

URL successfully copied!

Tap to zoom

ID: 137398

Vintage: 2004

In-line inspection conveyor

7500 Dots per hour glue and solder paste

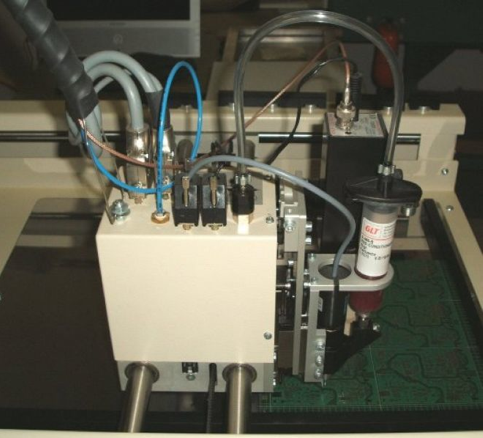

Archimedes pump for solder paste

Alignment camera system

Automatic for prototyping and serial production

CAD Data transmission possible

Software under Windows

2004 vintage.

DIMA Dotmaster SMDU 5001 is a precision pick and place equipment which offers precise placement of components on printed circuit boards (PCBs) in the production of consumer and commercial grade electronics. The system utilizes the latest in computer-controlled camera-blob recognition technology to accurately place components with minimal intervention from the user. Dotmaster SMDU 5001 is a cost-effective unit consisting of an industrial-grade vision component, advanced digital signal processing algorithms, and a proprietary user interface. The machine utilizes multi-colored part discrimination to read component reference marks and identify component configurations in real-time. The vision component adopts 8 cameras, lighting and lenses, providing the user with an advanced and precise tool for the recognition of components. The precision control of the air-tight component post creates uniform force along the entire component interface. This eliminates the risk of component misalignment due to unequal pressure on the component or substrate. The tool also incorporates sophisticated fault detection and correction software which can detect component misplacement, component skipping and component errors. The machine's automated design helps ensure reliability and minimize downtime. Additionally, the asset allows for component provisioning by batch or part for efficient parts replenishment and placement. The advanced features of the model increase the speed of operation, reduce component handling time and improve the efficiency of component picking and placement. DIMA Dotmaster SMDU 5001 is highly compatible with version 4 Gerber files, making it ideal for high-volume production. The equipment also provides an automated feeder tracking system to track and monitor pick and place activity at the individual station level. This allows users to quickly identify problems and take corrective action to ensure seamless production. In addition to its pick and place capabilities, the unit also offers other features such as component printing, tray or palletizing functions, barcode reading and verification, and automated verification processes. All these features make the machine suitable for a variety of applications and production processes. Overall, Dotmaster SMDU 5001 is a high-speed, cost-effective, and reliable pick and place tool that is capable of delivering an excellent pick and place capability in high-volume production environments. The asset is user-friendly, highly compatible with version 4 Gerber files, and offers a range of features which significantly reduce component handling time and improve efficiency.

There are no reviews yet