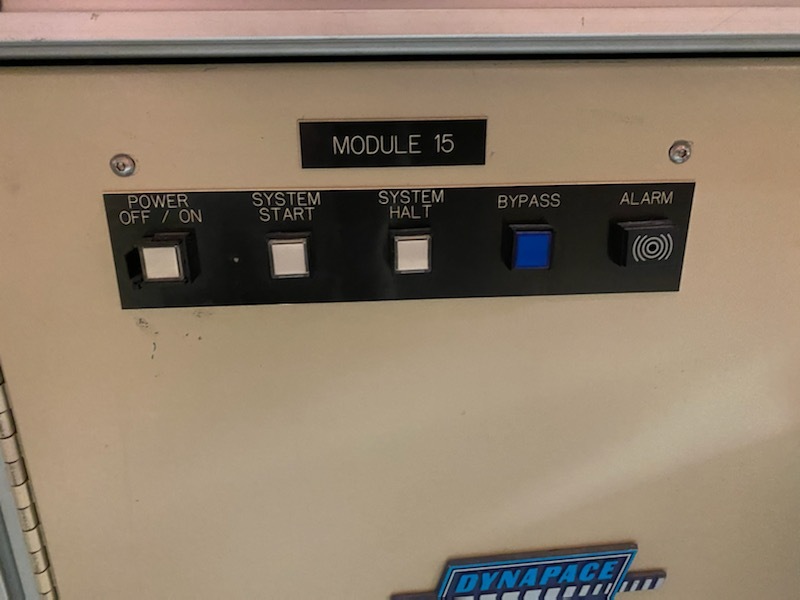

Used DYNAPACE 100232 #9354018 for sale

URL successfully copied!

Tap to zoom

DYNAPACE 100232 equipment is an industrial PC Board Assembly and Manufacturing system. It is designed for the assembly and production of printed circuit boards (PCBs). The unit is equipped with a variety of automatic assembly instrumentation, including a high-speed soldering machine, component pre-tensioners, and rework stations. This machine is tailored to the needs of high-volume production of quality PCBs and is optimized for rapid throughput. 100232 tool features a high-power soldering tool which quickly and accurately applies and heats up the components necessary for assembling a circuit board. Its automatic component pick-and-place asset is capable of placing components accurately on their respective places on the PCB in fractions of a second. The component pre-tensioners also accurately and quickly tension the components on the PCB ensuring a reliable connection. DYNAPACE 100232 model also features a rework station for precise debugging and repairs of any problems with the PCBs. This station is connected to a comprehensive and easy to use control and diagnostic interface, allowing the technician to quickly and accurately identify any fault locations on the PCBs. The equipment also provides built-in diagnostics for automated tests and checks on each produced board. The system also provides a range of other technical and customer support tools, such as PCB visualization software and component trackers. 100232 unit is equipped with a comprehensive real-time data capture machine, allowing for complete record keeping and production tracking of each board produced. This ensures full traceability of each board produced and an insight into the performance of the tool. DYNAPACE 100232 asset features a robust design, featuring an industrial standard construction with a high-end machine tool grade configuration. This ensures both optimal performance and endurance of the model. The equipment is powered by a modern and powerful Ethernet enabled control system, connected to a secure and reliable communication network. This enables operators to monitor and control the unit remotely and securely, without any risk of data loss or interference. 100232 is an intelligent and efficient machine for the production of high-quality printed circuit boards. It is easy to use and provides the optimal combination of performance, reliability, and cost-effectiveness. This tool allows production of PCBs at an industrial scale, with a variety of controlling and monitoring functions, and comprehensive data recording and tracking capabilities.

There are no reviews yet