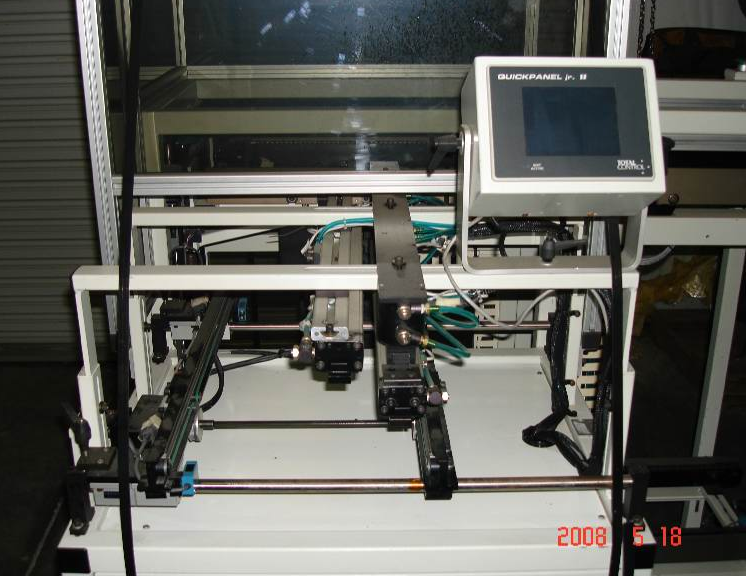

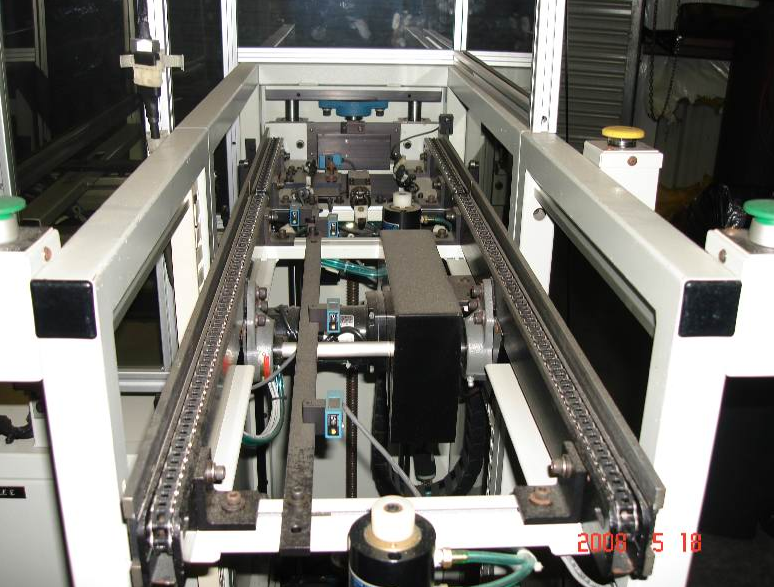

Used DYNAPACE Fifo #120944 for sale

URL successfully copied!

Tap to zoom

DYNAPACE Fifo is a comprehensive PC board assembly and manufacturing equipment designed to streamline the production process. The system utilizes the advanced First-In, First-Out (Fifo) process to ensure fast turn-around and predictable results. By providing an efficient manufacturing process that reduces unnecessary delays and lead times, DYNAPACE Fifo increases overall process efficiency and customer satisfaction. Fifo unit is composed of a fully-integrated software and hardware platform for the complete management and tracking of the entire PC board assembly process. The key Components of DYNAPACE Fifo include a powerful control and automation module, advanced data acquisition and monitoring machine, an innovation inventory control feature, and an optimized process control feature. The control and automation module of the tool ensures automated and precise control of the entire board assembly process. The asset's advanced data acquisition and monitoring model continuously track the process flow and provides real-time updates. The intuitive interface of the equipment helps simplify operations, reduce inputs and maximize process efficiency. The innovation inventory control system of Fifo ensures that materials are always available for the production process, allowing for continuous flow. The optimized process control unit allows for efficient tracking of production orders, as well as better optimization of the assembly process. DYNAPACE Fifo also offers reliable support and maintenance services to ensure an efficient and smooth running of the machine—always. The tool delivers maintenance services such as preventive service, remote online maintenance and repair, and asset structure and network diagnostics monitoring. In addition, the software platform guarantees increased model uptime, improved crisis response and reduced repair time. Fifo's PC board assembly and manufacturing equipment is reliable and dependable.* Additionally, it is designed to maximize efficiency and productivity, while cutting down on production expenses and production time. The end result is efficient and quickly finished board assemblies that are of high quality, ensuring customer satisfaction.

There are no reviews yet