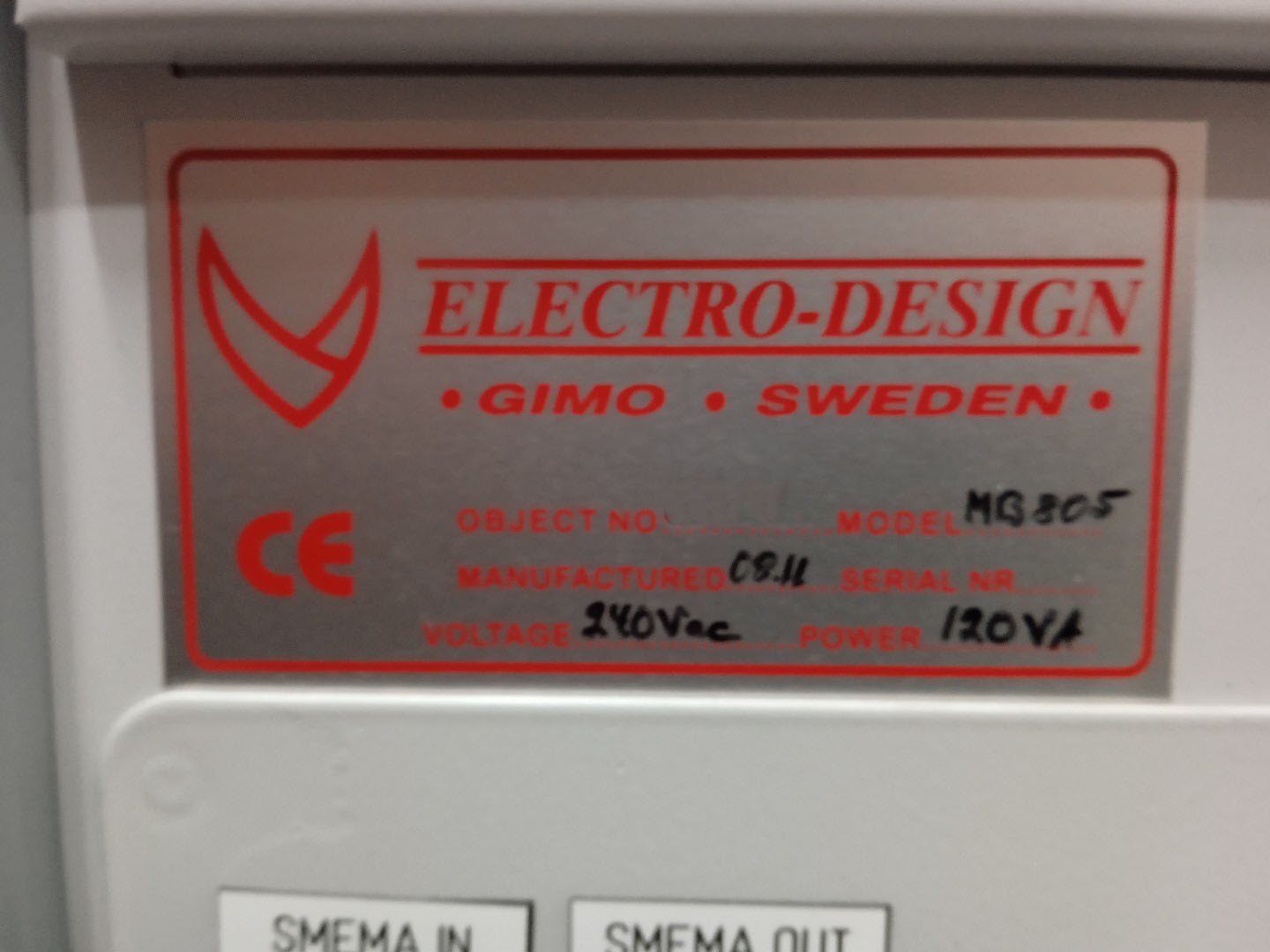

Used ELECTRO DESIGN MB 805 #293585603 for sale

URL successfully copied!

Tap to zoom

ELECTRO DESIGN MB 805 is a PC Board Assembly and Manufacturing Equipment designed to help streamline and optimize the fabrication process and help produce high-quality components while reducing costs. The system makes use of advanced hardware and software solutions to provide a streamlined and efficient process for assembling printed circuit boards (PCB). The unit includes an intuitive software interface to help streamline the design process. It enables users to specify their design requirements, including board size, component layout, and any extra requirements. The machine then allows for simulations to be run which help identify and minimize errors prior to physical production. MB 805 also makes use of automated component placement (ACP) technology to place and operate components reliably. This helps to dramatically reduce PCB fabrication time, while also resulting in fewer errors compared to manual component placement. The tool also offers a self-learning capability which increases the accuracy of component placement as it is used more often. This can greatly improve production yields and significantly reduce rework. In addition, the asset also integrates with a variety of manufacturing processes. This allows users to link data between their boards and machinery, making it easier to identify any issues during the production process. This also helps reduce labor costs associated with inspecting and testing components during the manufacturing process. Finally, ELECTRO DESIGN MB 805 also offers a variety of diagnostic tools to help identify and correct any potential defects. This can help improve production yields by ensuring fewer defective boards are produced. It also helps streamline the maintenance process, as any potential problems can quickly be identified and addressed. Overall, MB 805 is a comprehensive PC Board Assembly and Manufacturing Model designed to help improve the fabrication process and help produce high-quality components while reducing costs. It makes use of advanced hardware and software solutions to provide a streamlined and efficient process for assembling printed circuit boards (PCBs). Additionally, it also helps to identify and correct any potential defects, giving users a reliable and effective equipment for producing boards with maximum efficiency.

There are no reviews yet