Used ELECTROVERT / SPEEDLINE Aquastorm 100C #9045533 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9045533

Vintage: 2013

In-line cleaner

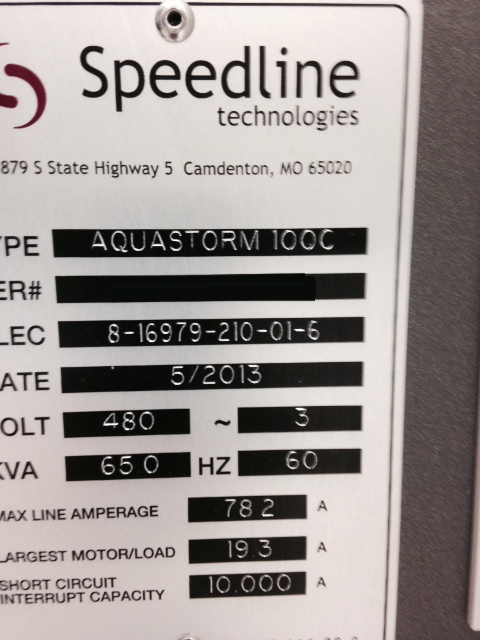

Model: AS100C

Max line amperage: 78.2 A

Largest motor/load: 19.3 A

Short circuit interrupt capacity: 10,000 A

480 V, 3-Ph, 65 kVA, 60 Hz

Process width: 20"

Exit extension: yes

Prewash nozzle: V-Jet

Wash configuration: Hurr

Final rinse nozzles: V-Jet

2013 vintage.

ELECTROVERT / SPEEDLINE Aquastorm 100C is a versatile and efficient printed circuit board (PCB) assembly and manufacturing equipment. It is ideal for a wide range of applications from medium to high-volume production. It is a cost-effective production system with the efficiency of automated assembly, inspection, and testing. SPEEDLINE Aquastorm 100C uses a series of conveyors, belts, and transport systems to move and coordinate the PCBs throughout each production phase. This unit helps to increase speed and consistency while minimizing the use of manual labor. This allows manufacturers to have faster time-to-market with their products. This machine offers a comprehensive range of component placement capabilities. It supports both automated and manual component placement, using a range of nozzles and head configurations. This provides a high degree of flexibility to accommodate different component types and sizes. The tool also includes high-precision vision inspection for accurate placement. ELECTROVERT Aquastorm 100C has a high-speed pick-and-place platform that can be configured to meet a variety of applications. This achieves a flexibly high placement rate up to 9,900 components per hour. It also has a range of software-driven features allowing the user to optimize the manufacturing process. This includes creating a pick-and-place recipe for specific components, performing custom placement, and managing product/part changeovers, all of which can be customized to meet a customer's precise requirements. This asset also offers a variety of thermal process options such as wave soldering and reflow soldering for component attachment. For maximum production throughput and flexibility, the model can also be configured with a conveyance equipment with multiple soldering destinations. Aquastorm 100C also includes a full range of post-production tests, inspection, and other automated processes. This includes optically through-hole inspection, and x-ray inspection for via fill verification as well as black/white inspection for solder joint integrity. This helps to ensure product quality and reliability. Overall, ELECTROVERT / SPEEDLINE Aquastorm 100C provides a comprehensive and economical manufacturing system with a range of efficient features and tools. It helps to reduce production cost, time, and effort, while ensuring a high quality and reliable product.

There are no reviews yet