Used ELECTROVERT / SPEEDLINE Aquastorm 200 #9154547 for sale

URL successfully copied!

Tap to zoom

ID: 9154547

Vintage: 2009

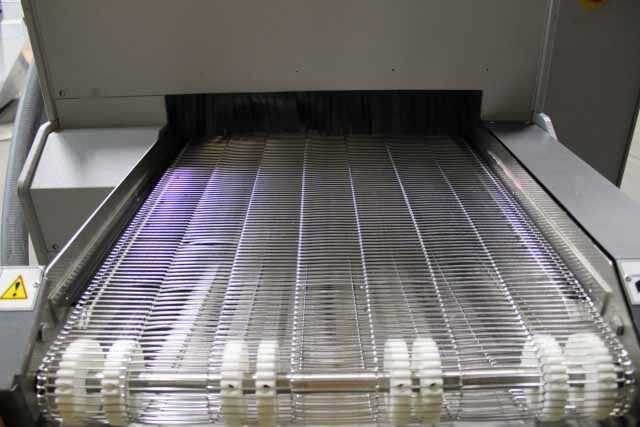

In-line cleaner

Chemical isolation

Specifications:

Digital flow meters

Integrated sump tank with effluent transfer

PC Closed loop conveyor speed

Orbitally welded stainless steel plumbing

Triple welded tanks

Standard V jet spray nozzles

Hurricane jets

Isolation module for aqueous-based chemistries

Electro air knife drying

Incline conveyor, 30"

Auto standby photocell

Resys 204 transfer station

(2) Transfer stations

25 Gallon tank capacity

Polypropylene cabinet with integrated storage tank

Polypropylene float sensors in tank and pump tray

High temperature filter housing

Differential pressure gauges

Check valve on system output

High level alarm

2009 vintage.

ELECTROVERT / SPEEDLINE Aquastorm 200 is a revolutionary new PC Board assembly and manufacturing equipment, designed to revolutionize modern PCB production processes. SPEEDLINE Aquastorm 200 offers best-in-class through-hole reflow and wave soldering technology, plus a range of automated process control features for supporting quality assurance requirements. The system is built with top-of-the line components and features a prism chamber, TLF series wave soldering machine, and integrated 4-axis robot gantry unit. The integrated robotics technology allows precise selection and placement of components for assembly. The machine is set up to be easily programmed and monitored by the user, offering users the flexibility to customize and set up the tool according to their specific needs. With its robust design and colorful graphic display, ELECTROVERT Aquastorm 200 is both durable and visually appealing. Aquastorm 200 features a wide range of process control features, allowing the user to optimize results and maintain high levels of quality assurance. The asset has an integrated temperature profiling model for pre-determing the best soldering profile for each type of component being soldered. It also has a programmable oxygen density control equipment for accurate soldering with minimal flux airborne exposure. The process is further protected against defects through the use of dual loop soldering flux management to prevent component bridging and a metal carriage for thorough board clearance. In addition to process control features, ELECTROVERT / SPEEDLINE Aquastorm 200 is designed to help users achieve higher production rates with its high-speed conveyor system. The unit is loaded with features designed to get the job done quickly and efficiently, such as fast acceleration speeds, rapid profiling, and a wide range of process parameters. The conveyor also has an over-tank drive for smooth, steady production, and a self-locking mechanism for reliable delivery of product. SPEEDLINE Aquastorm 200 is a powerful addition to any PCB assembly and manufacturing line, offering robust process control for improved cost savings and faster production rates. Its easy-to-use interface, intuitive design, and efficient features make it a great choice for board designers and manufacturers. With its clear operational advantages, ELECTROVERT Aquastorm 200 is an ideal choice for companies looking to improve their PCB manufacturing process.

There are no reviews yet