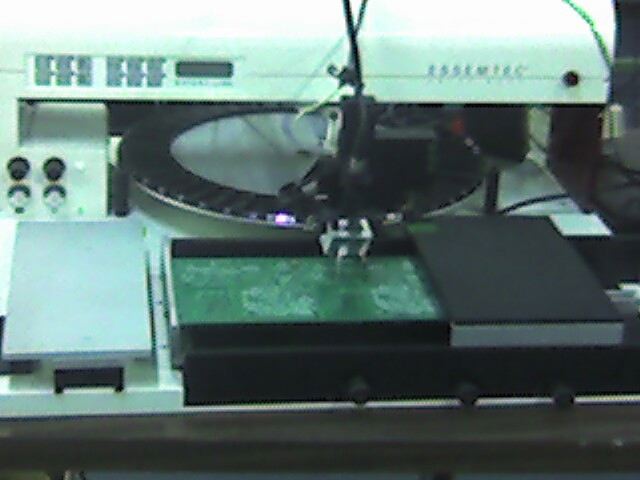

Used ESSEMTEC Expert M #49705 for sale

URL successfully copied!

Tap to zoom

ID: 49705

Vintage: 1996

Manual Pick & Place Machine with vision camera

Placement speed: 400-600cph

Maximum PCB size: 425x253 mm

Smallest Chip: 0201

Minimum lead pitch: 0.6 mm

Monitor

Carousel

Theta adjust from the manipulator and the board level

1996 vintage.

ESSEMTEC Expert M is a versatile, cost effective pc board assembly and manufacturing equipment. It is equipped with a set of unique features which makes it one of the most efficient systems currently available in the market. It has been designed to provide a comprehensive solution for high volume and prototype manufacturing requirements, with a wide range of capability and performance. Expert M comes with a powerful dual motor-driven head assembly and offers up to a 1.3mm resolution and repeatable accuracy down to 0.3mm which allows for precise component placement. This feature also allows for an efficient, high-speed production cycle which can reduce the production time significantly. It can handle both through-hole and surface mount components, achieving an impressive component width of 0.2mm up to a component height of 10mm. The system is also equipped with innovative components such as an automated material handling unit, dynamic component library and intelligent production line management. The automated material handling machine can provide component identification, component placement, component packaging and component tracking. The dynamic component library allows users to quickly and easily search for specific component details and placement and it can also store component data for future use. The intelligent production line management provides users with the ability to store assembly results and generate detailed production reports. The tool can also be integrated with pick and place equipment, component bookholding systems and anti-static devices to maximize the production capabilities. An integrated housekeeping asset enables tools and materials to be stored securely while an optional traceability module provides complete component tracking. ESSEMTEC Expert M is specifically designed to be user-friendly and is capable of performing a variety of complex assembly tasks. The easy-to-use graphical user interface ensures operations are intuitive and hassle-free. A built-in diagnostic model also helps to identify errors during assembly processes. In summary, Expert M provides users with a cost effective, streamlined equipment for assembly and manufacturing of pc boards. It is equipped with impressive features such as a powerful dual motor-driven head assembly, automated material handling system, dynamic component library and intelligent production line management, to ensure efficient production cycles. It can handle both through-hole and surface mount components with high accuracy and repeatability, making it a highly sought after production solution.

There are no reviews yet