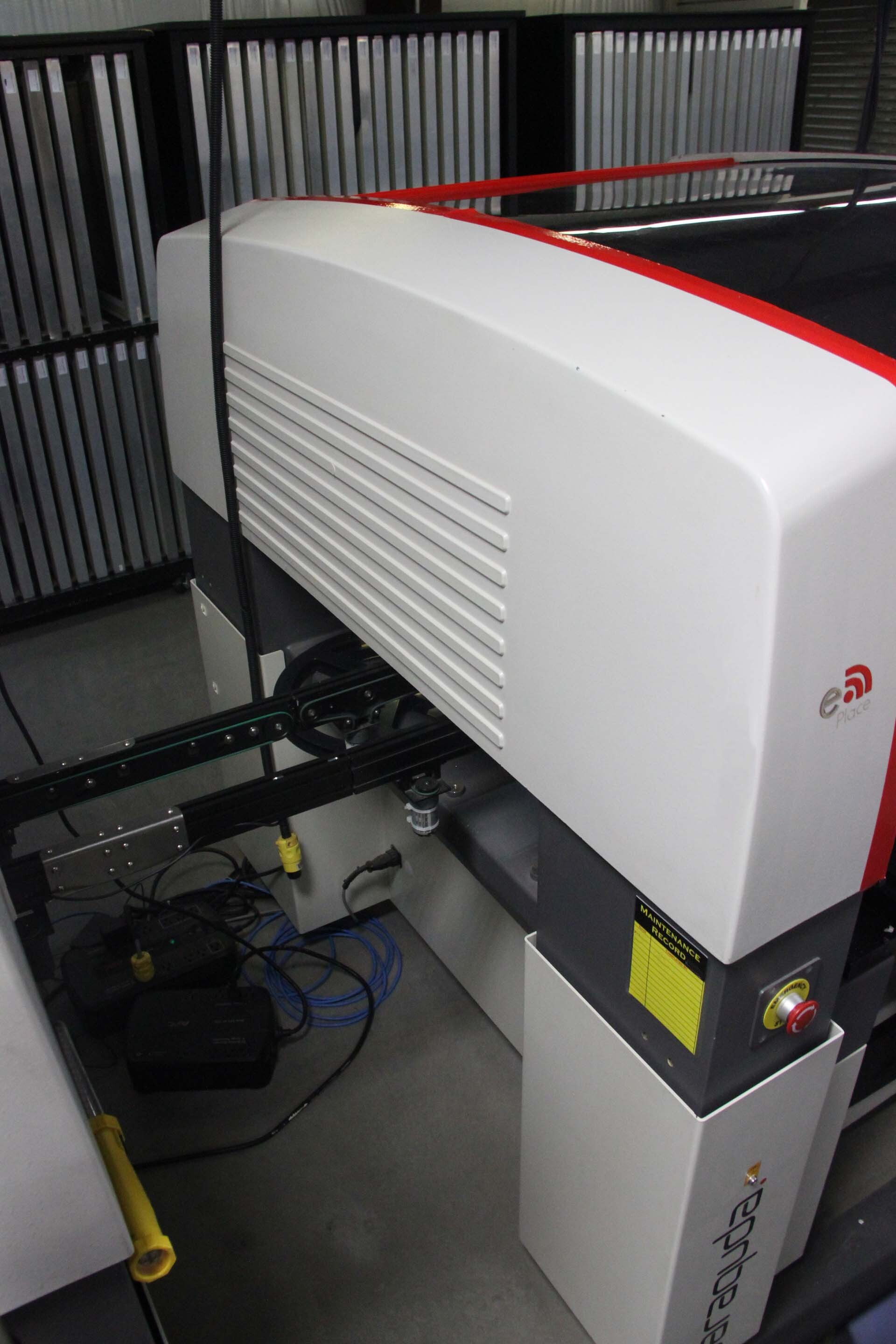

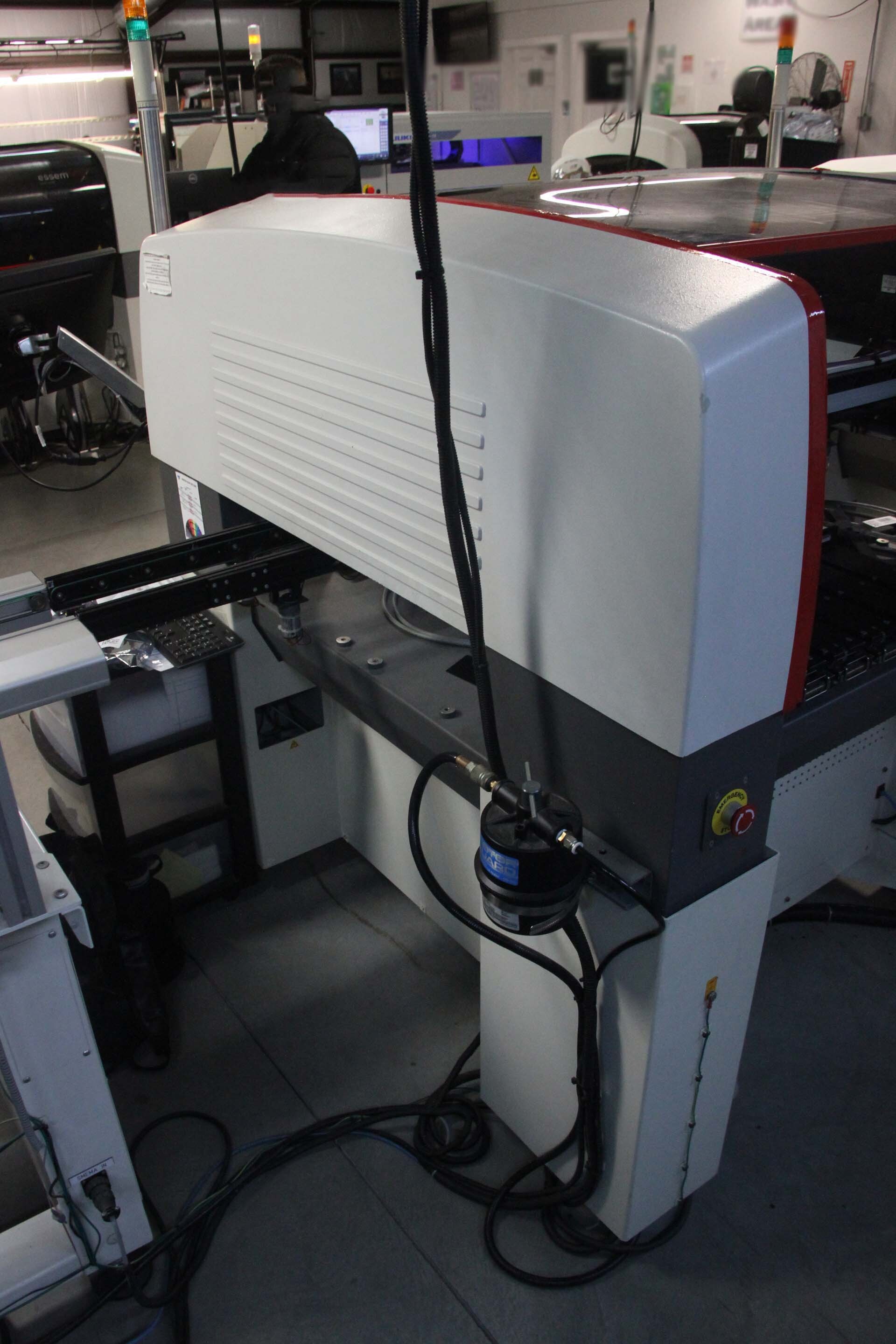

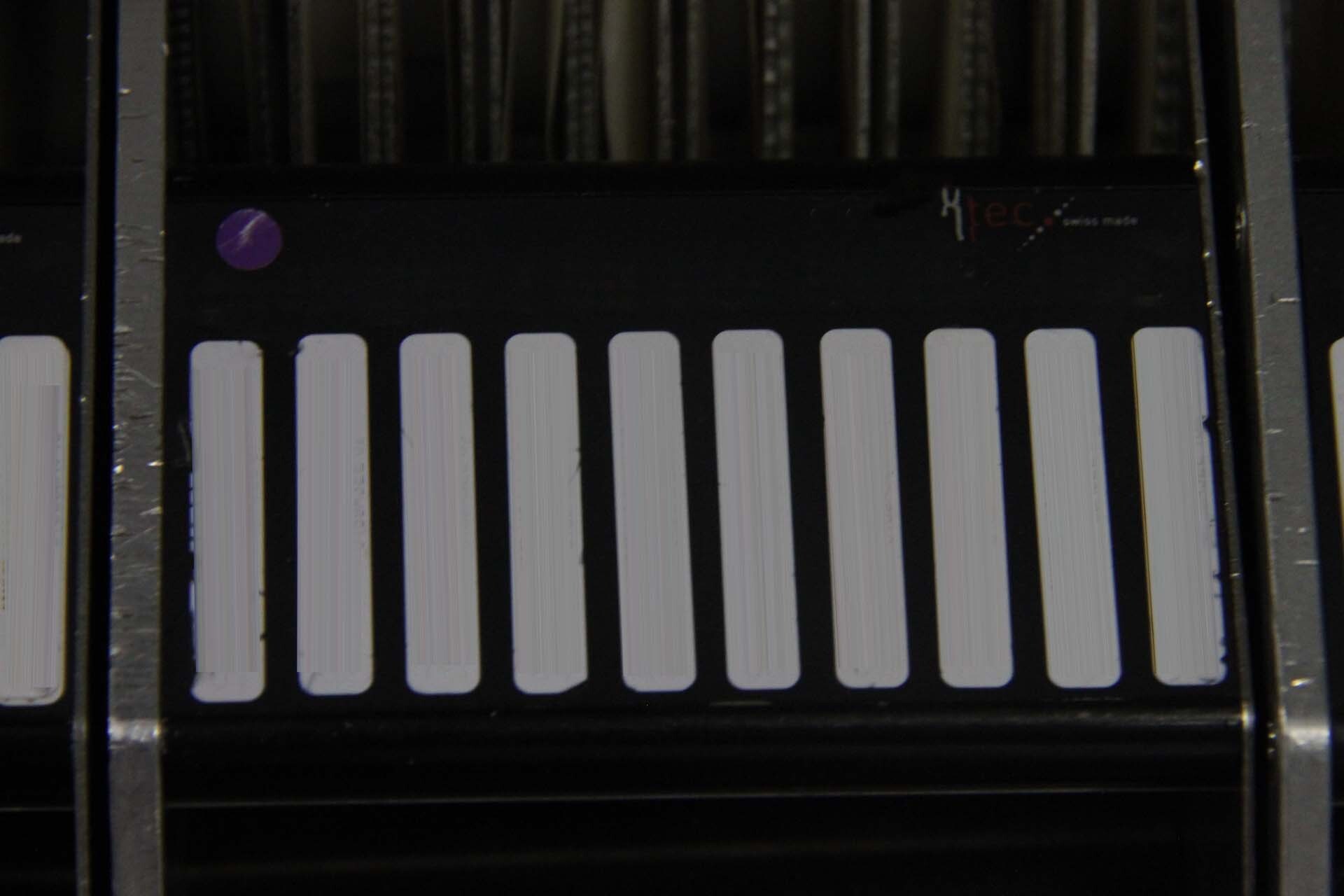

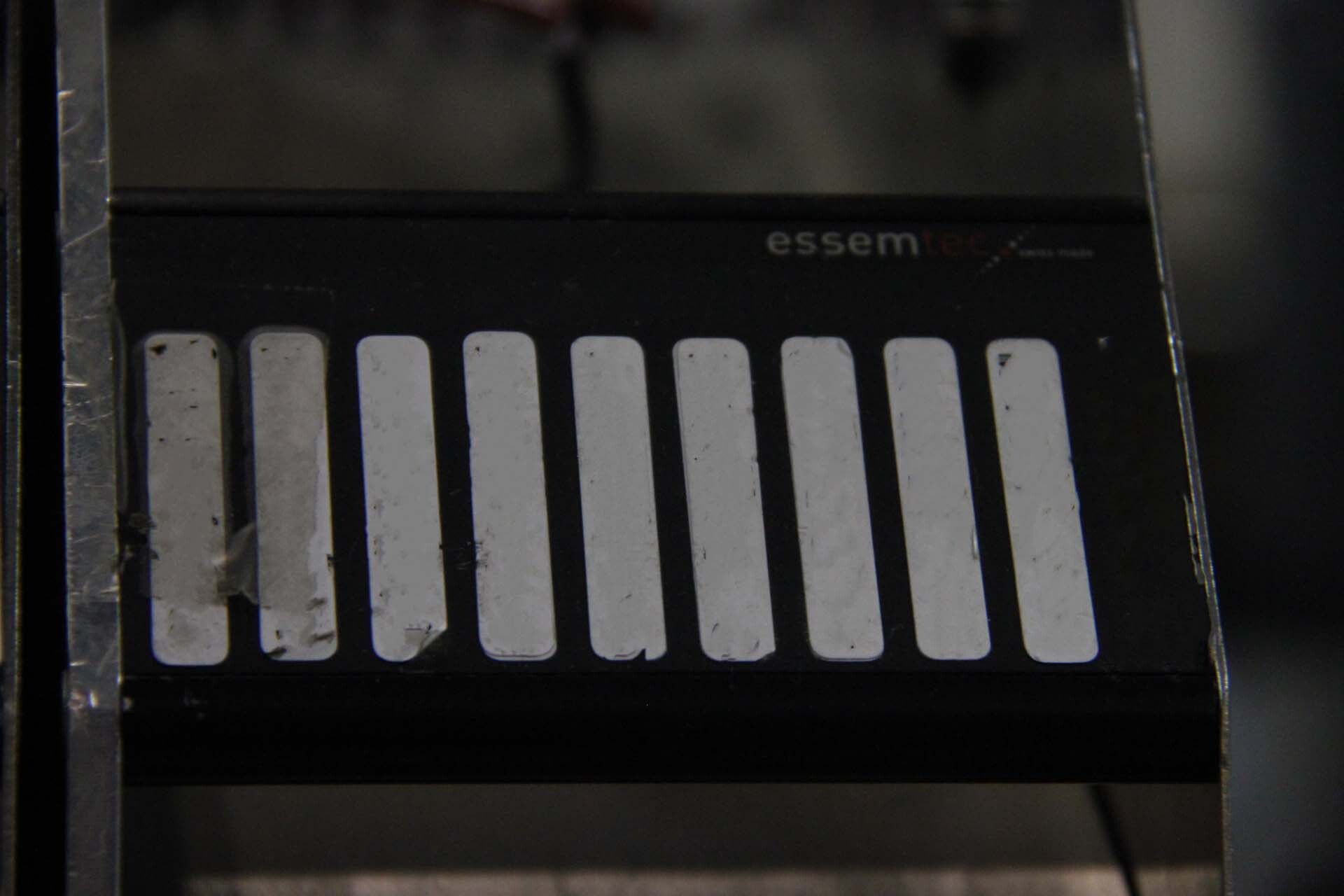

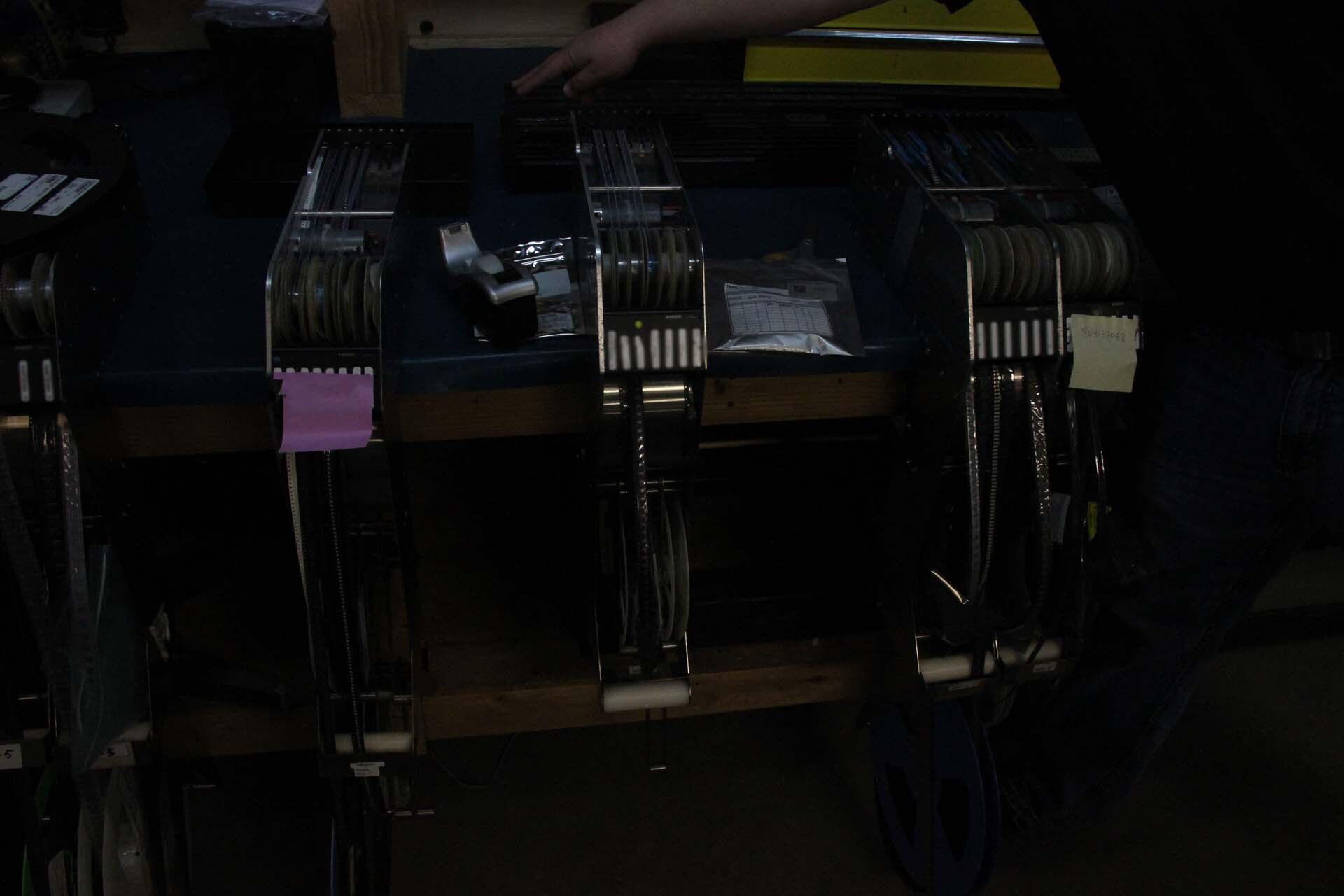

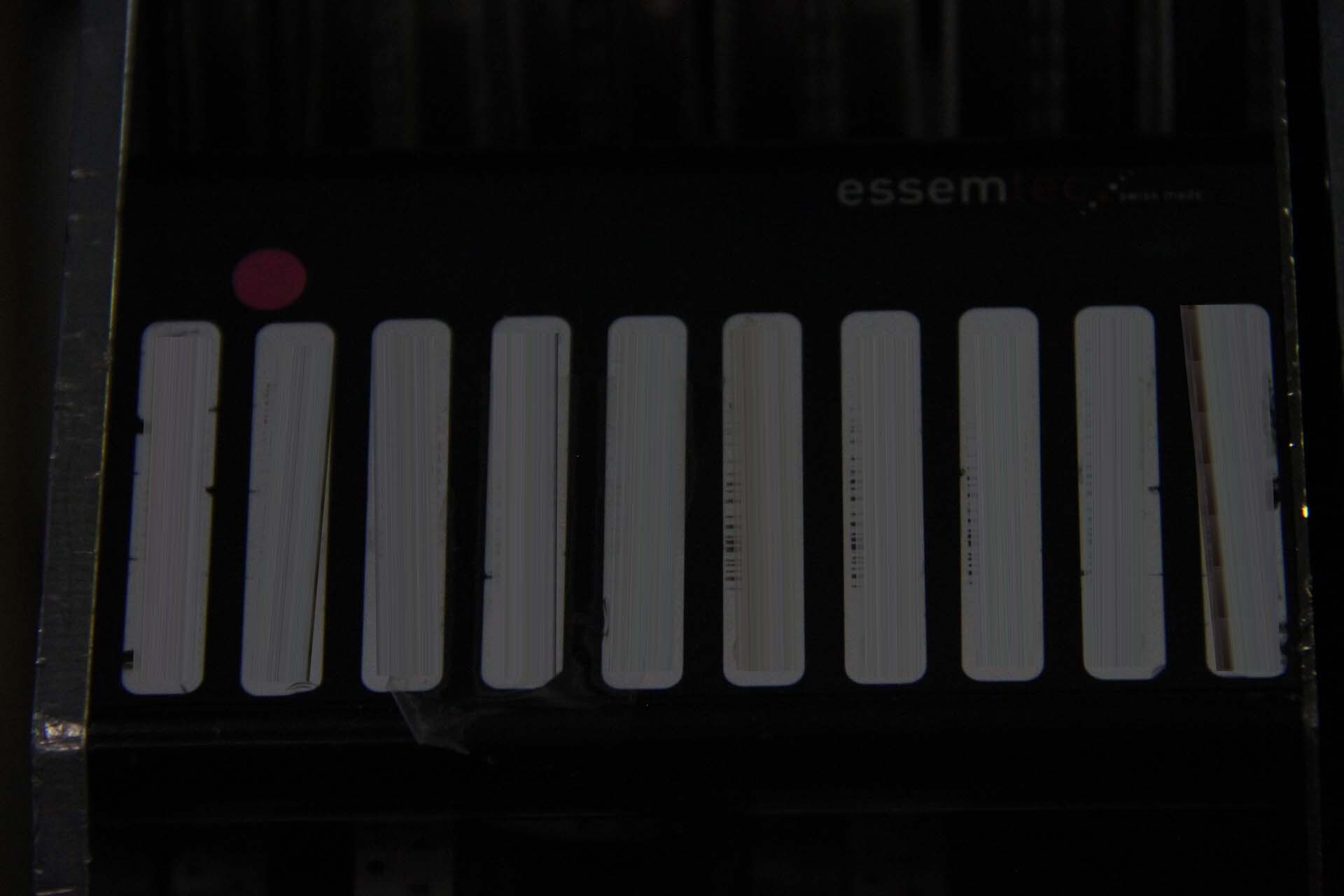

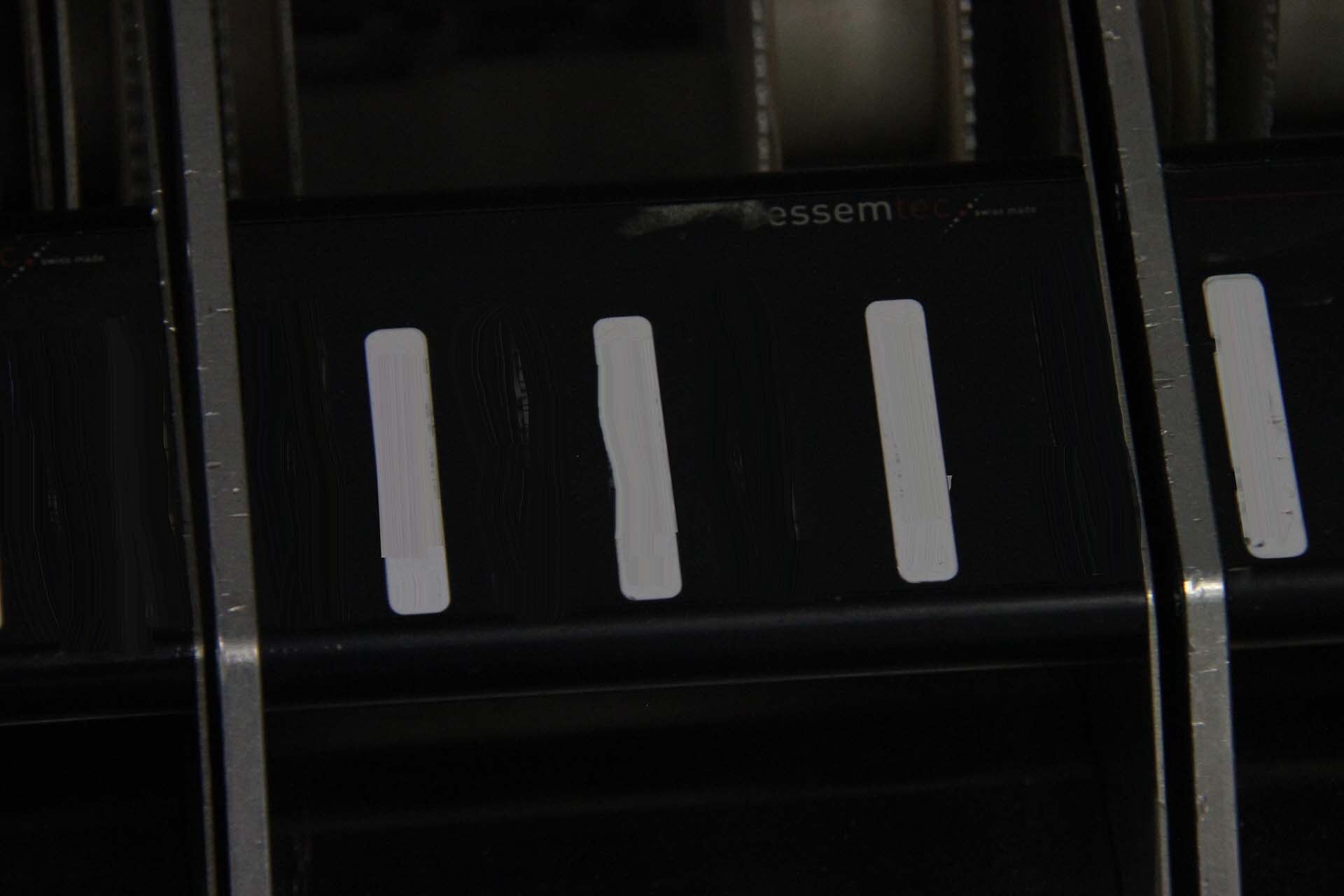

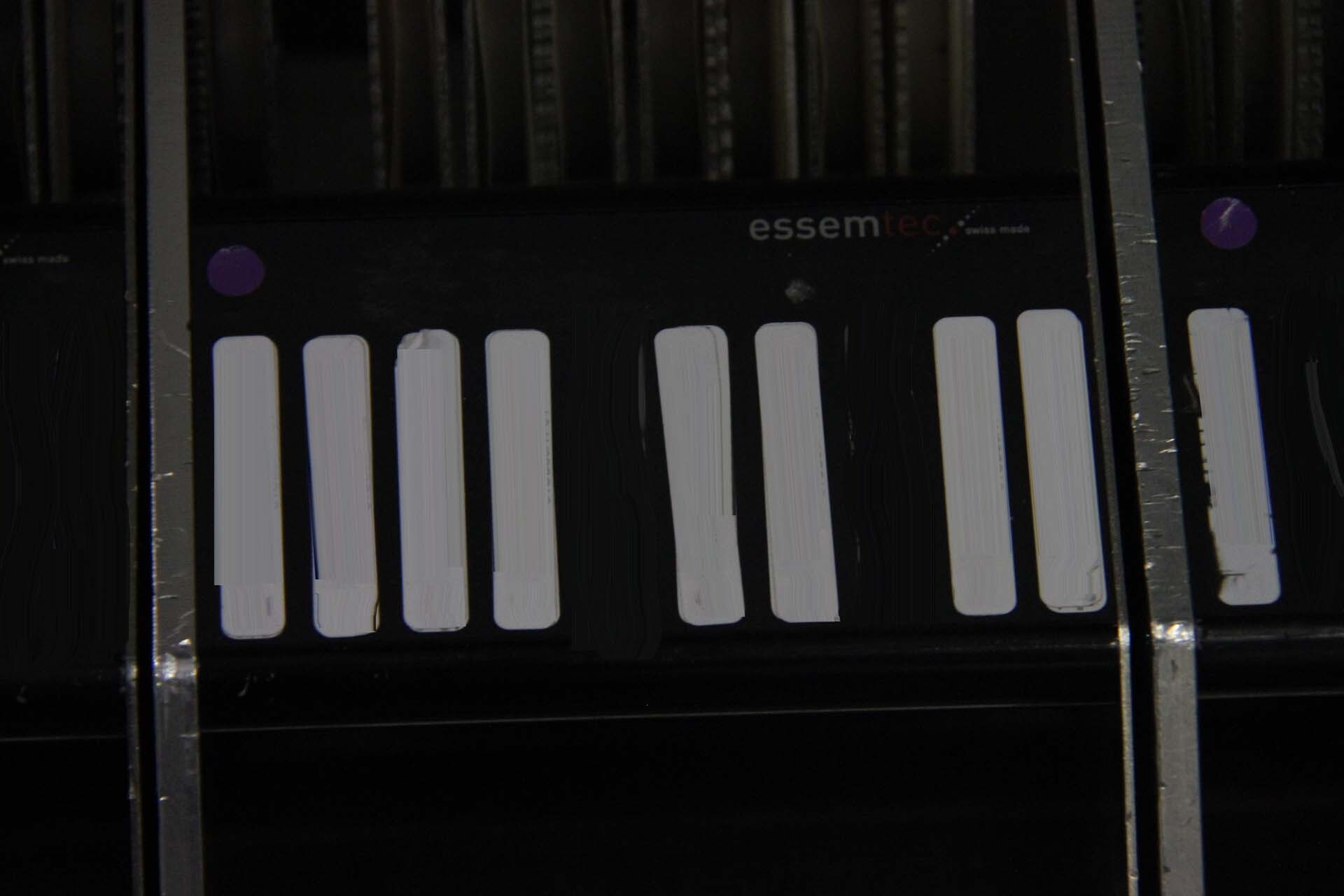

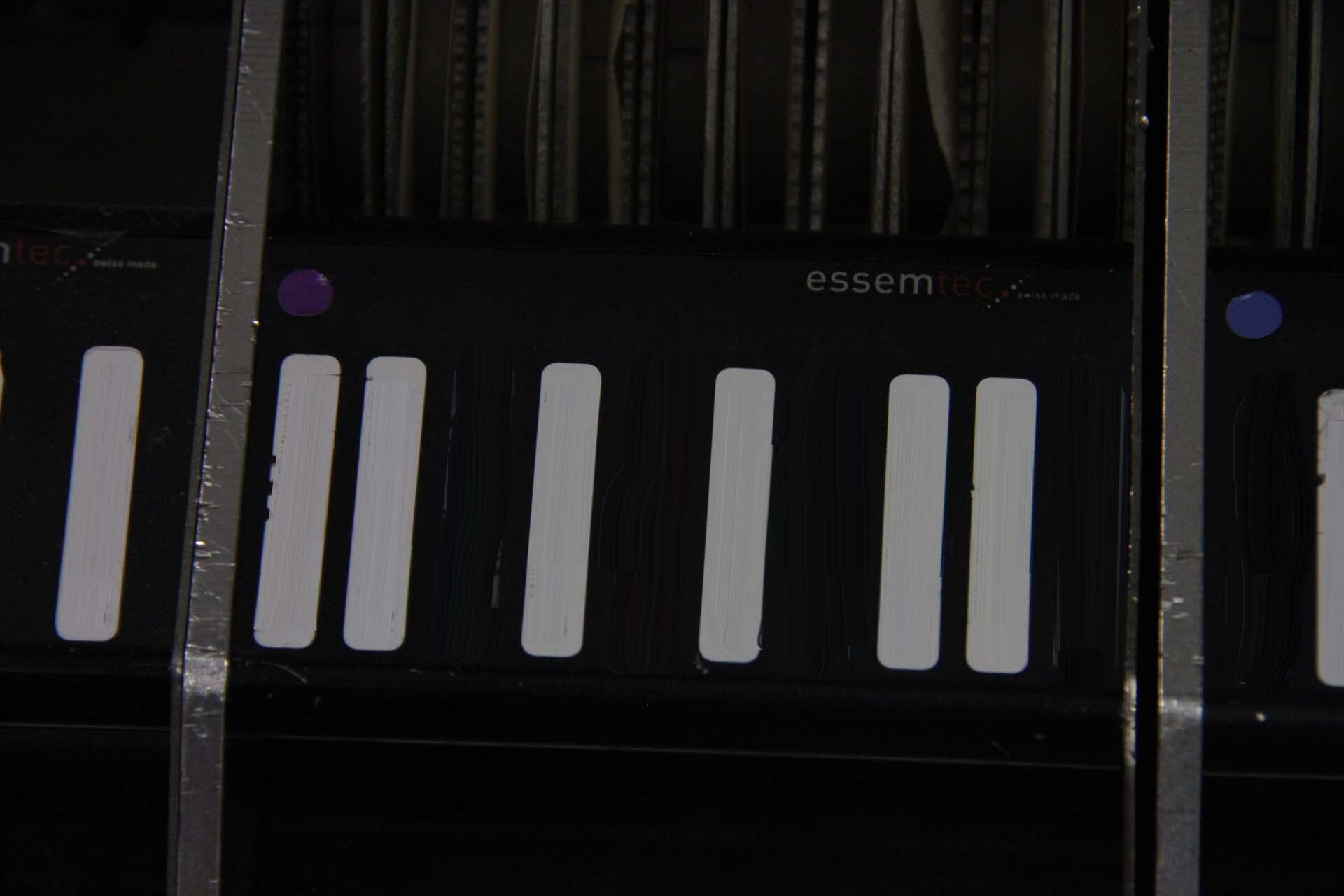

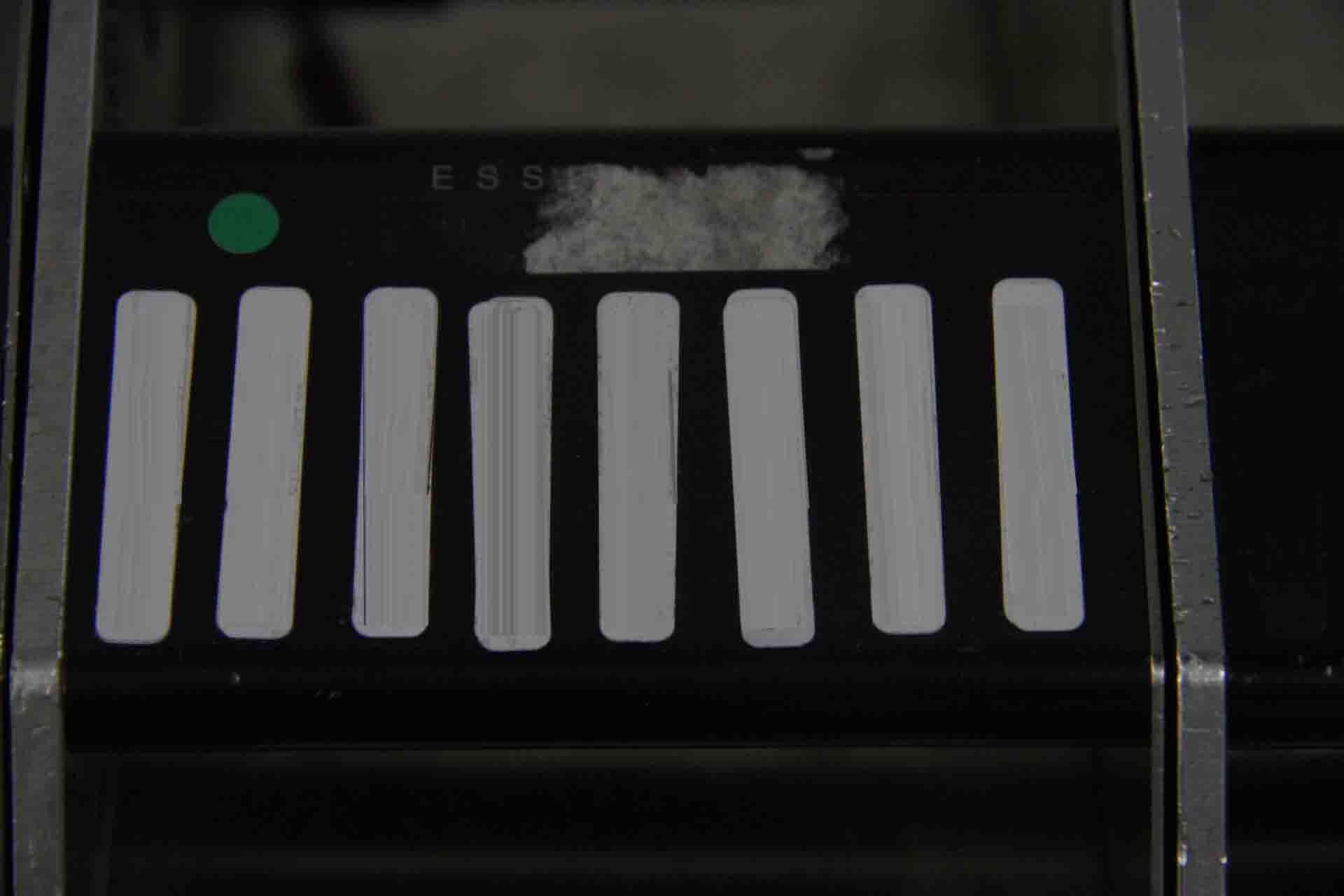

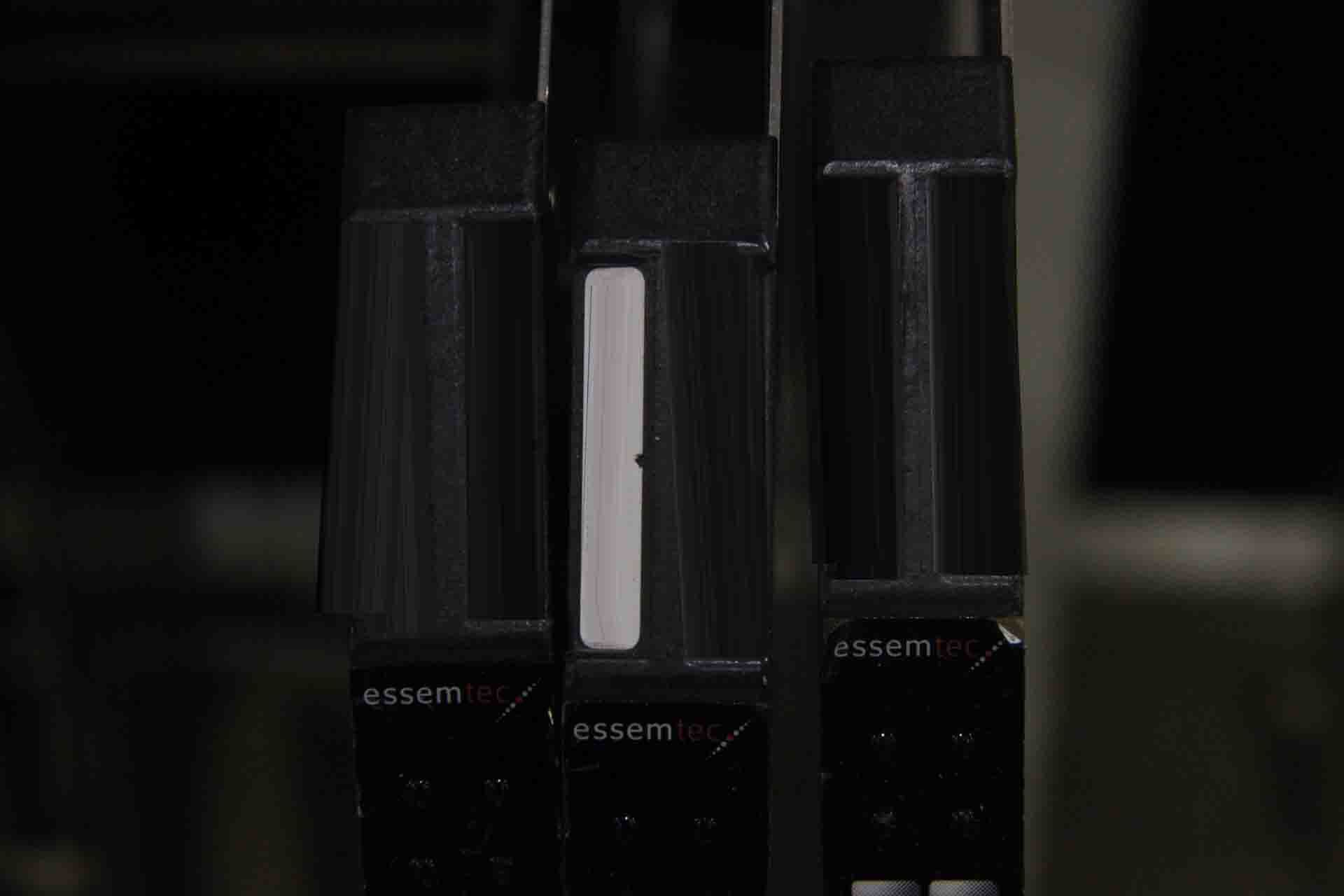

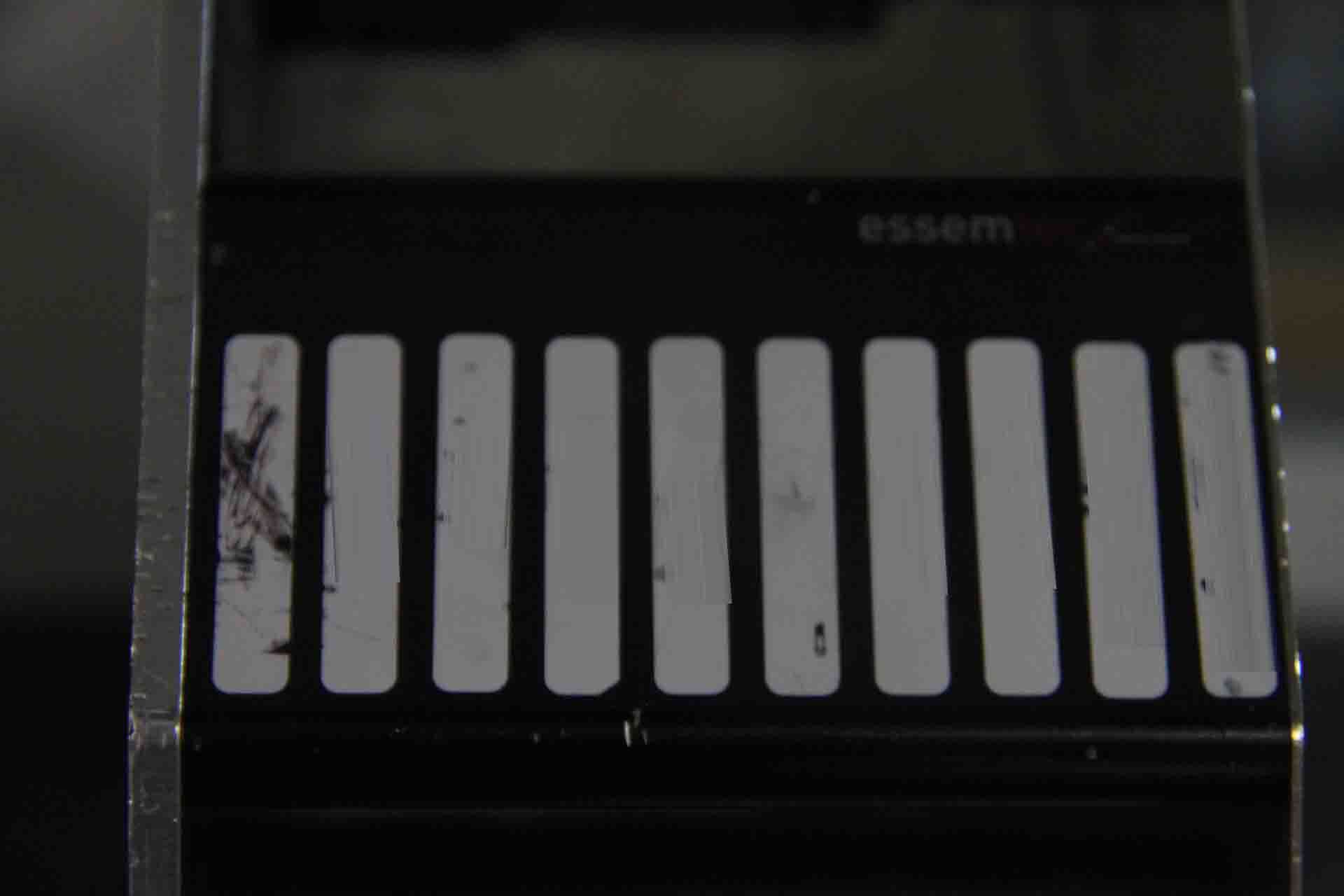

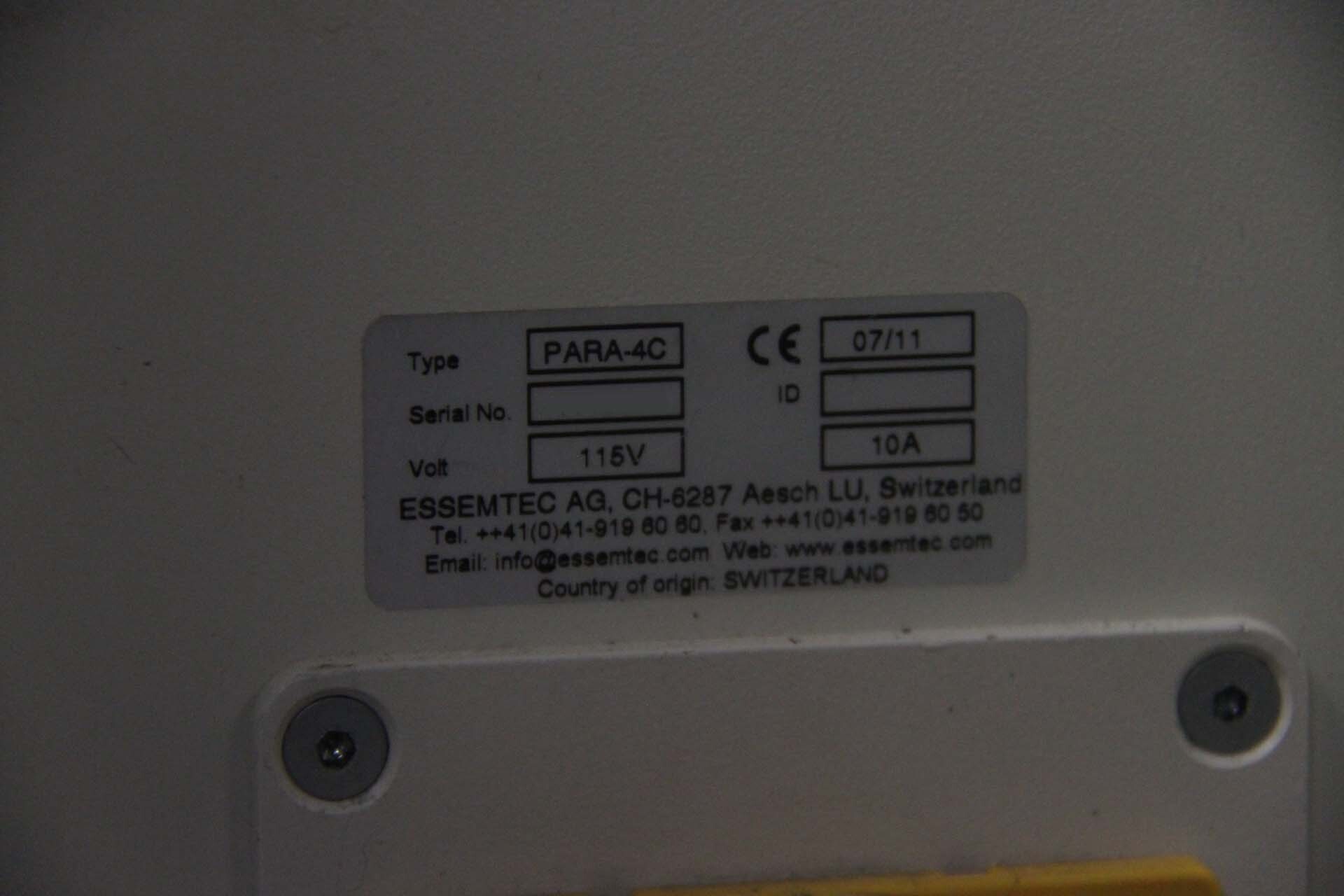

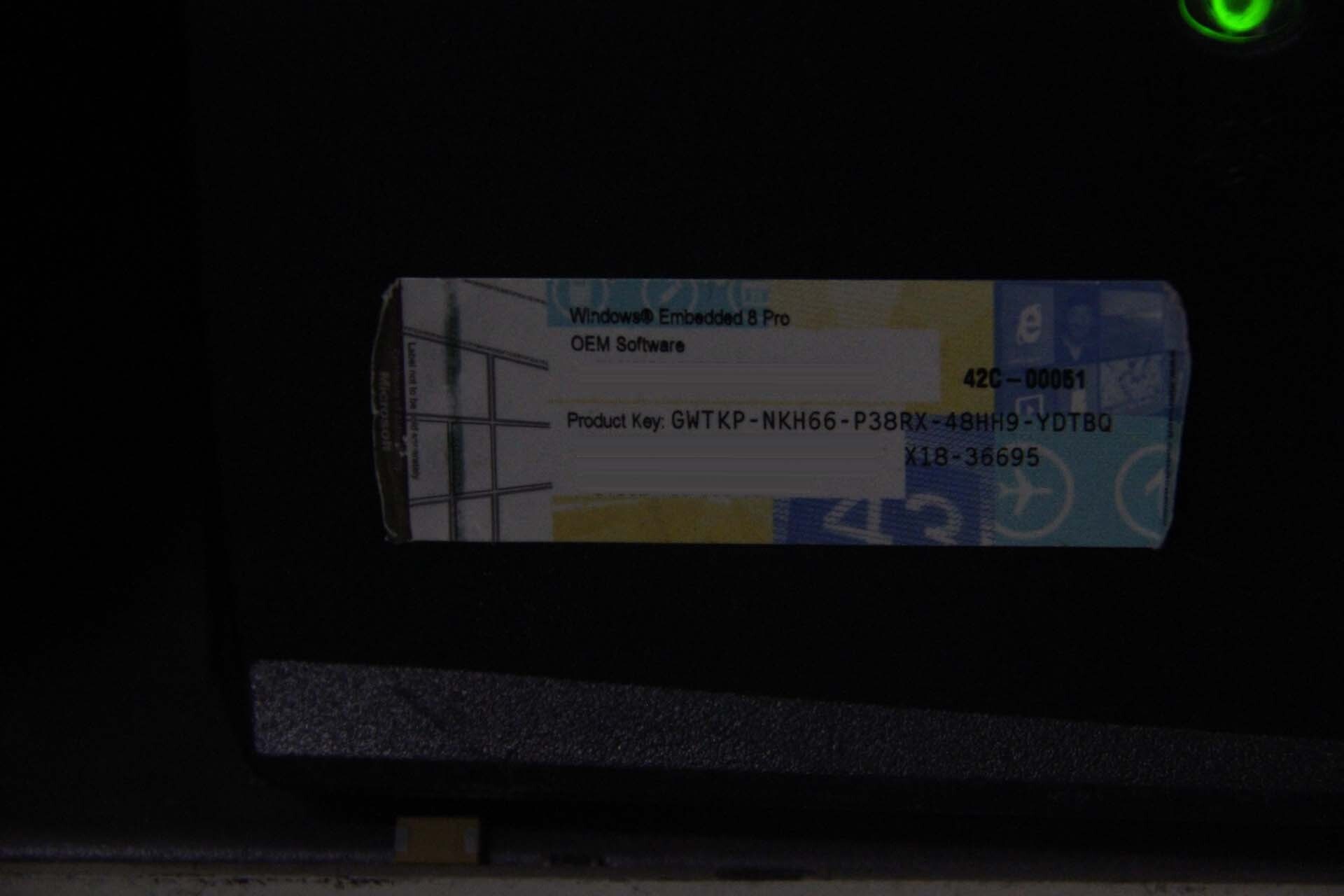

Used ESSEMTEC Paraquda #293653109 for sale

URL successfully copied!

Tap to zoom

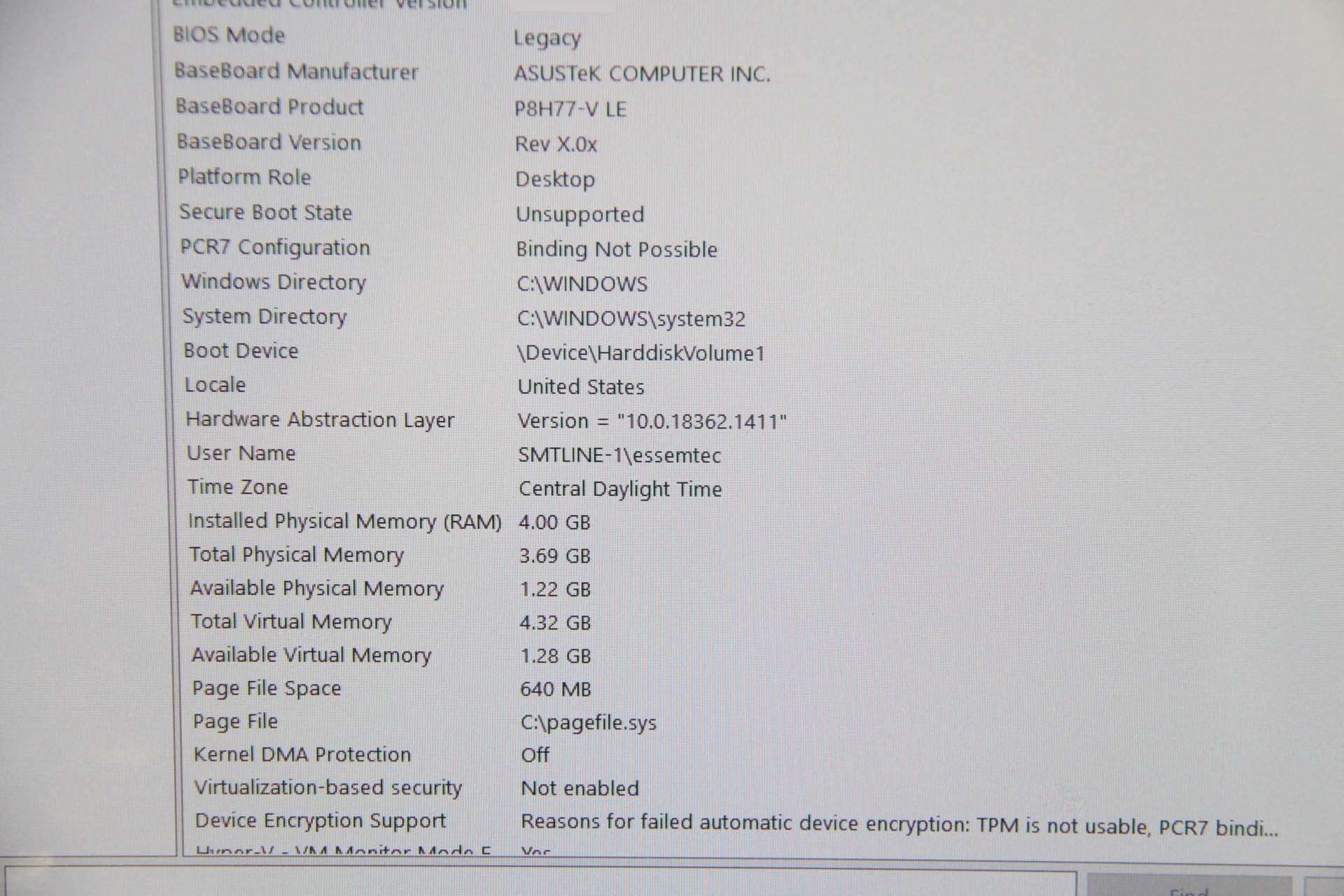

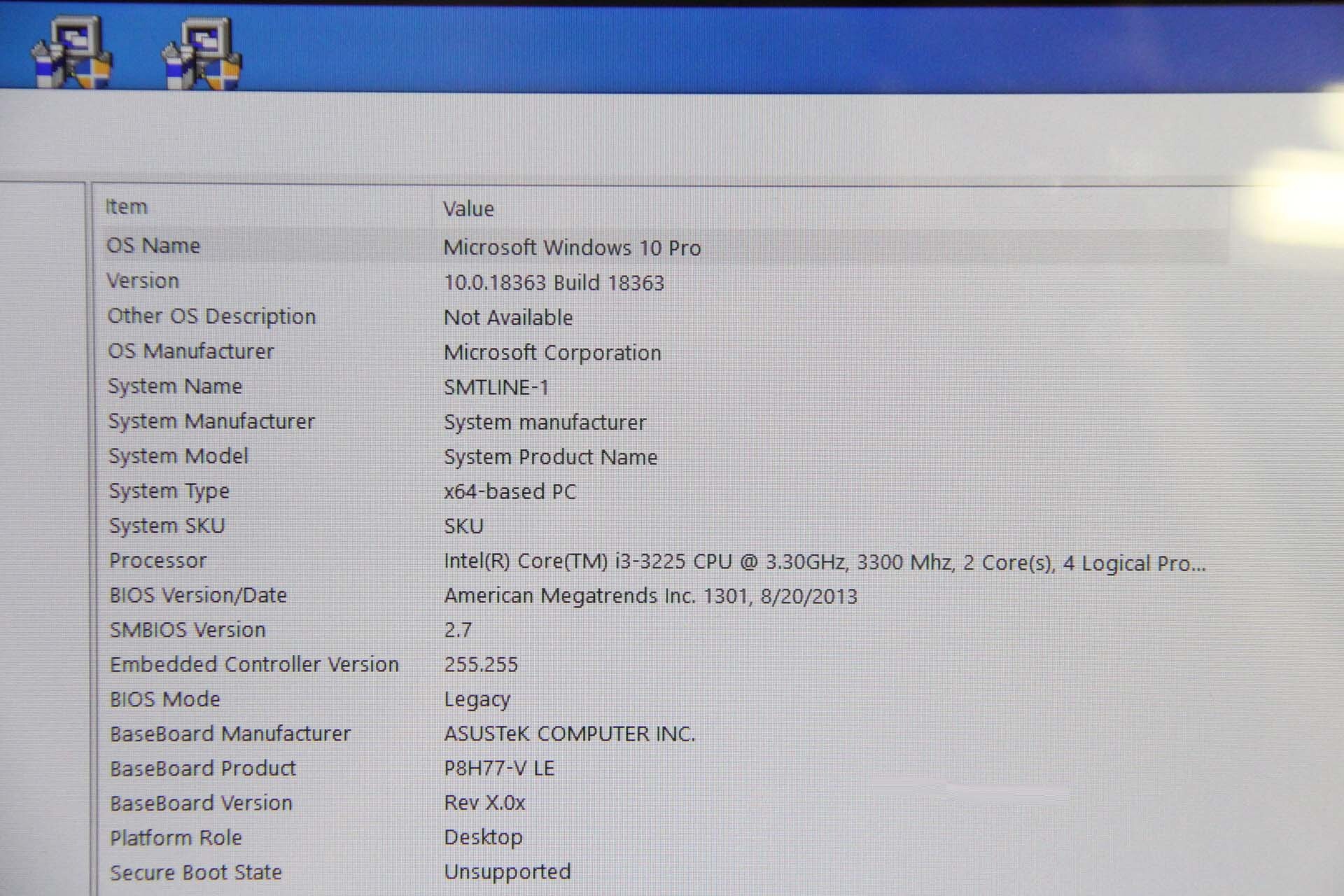

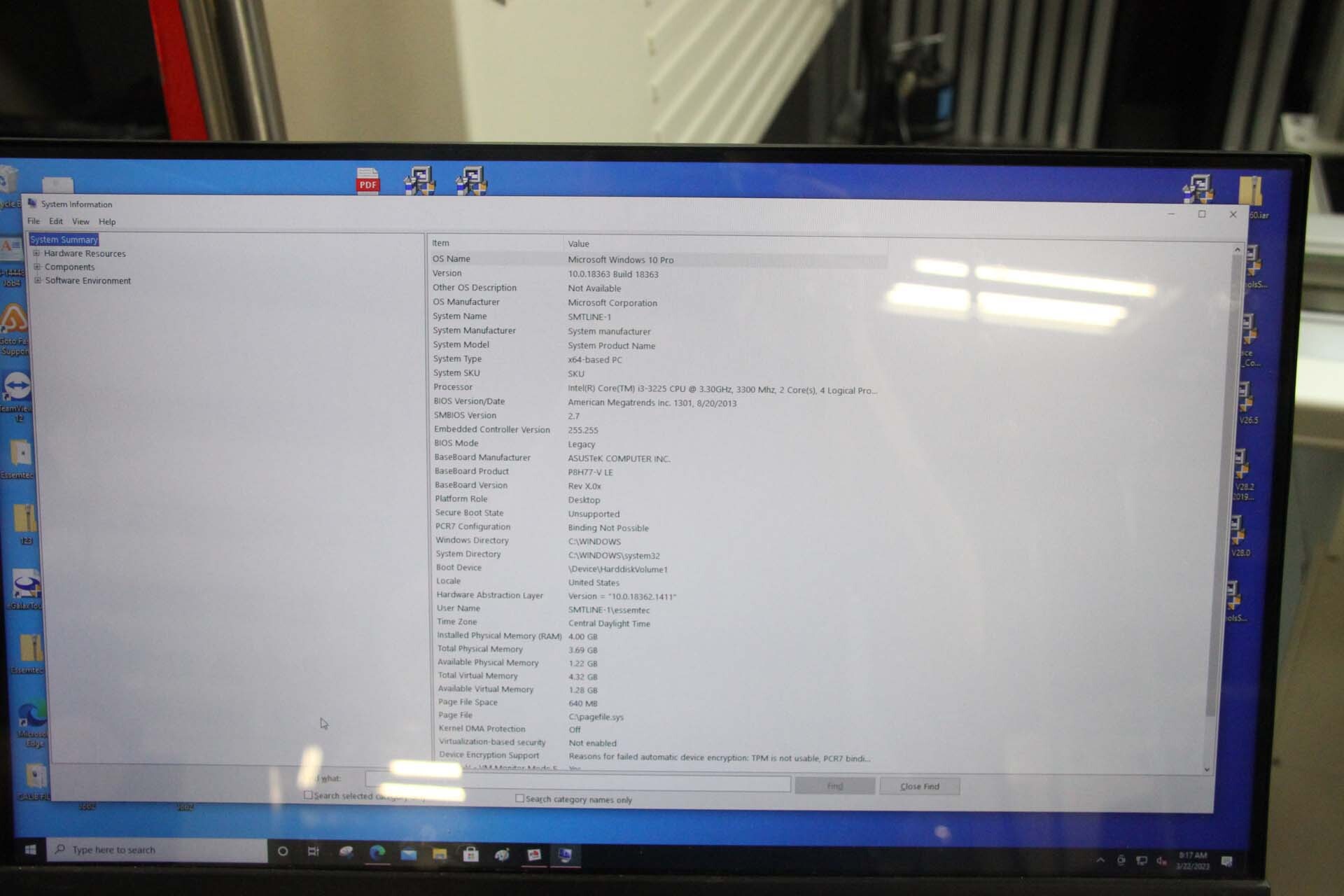

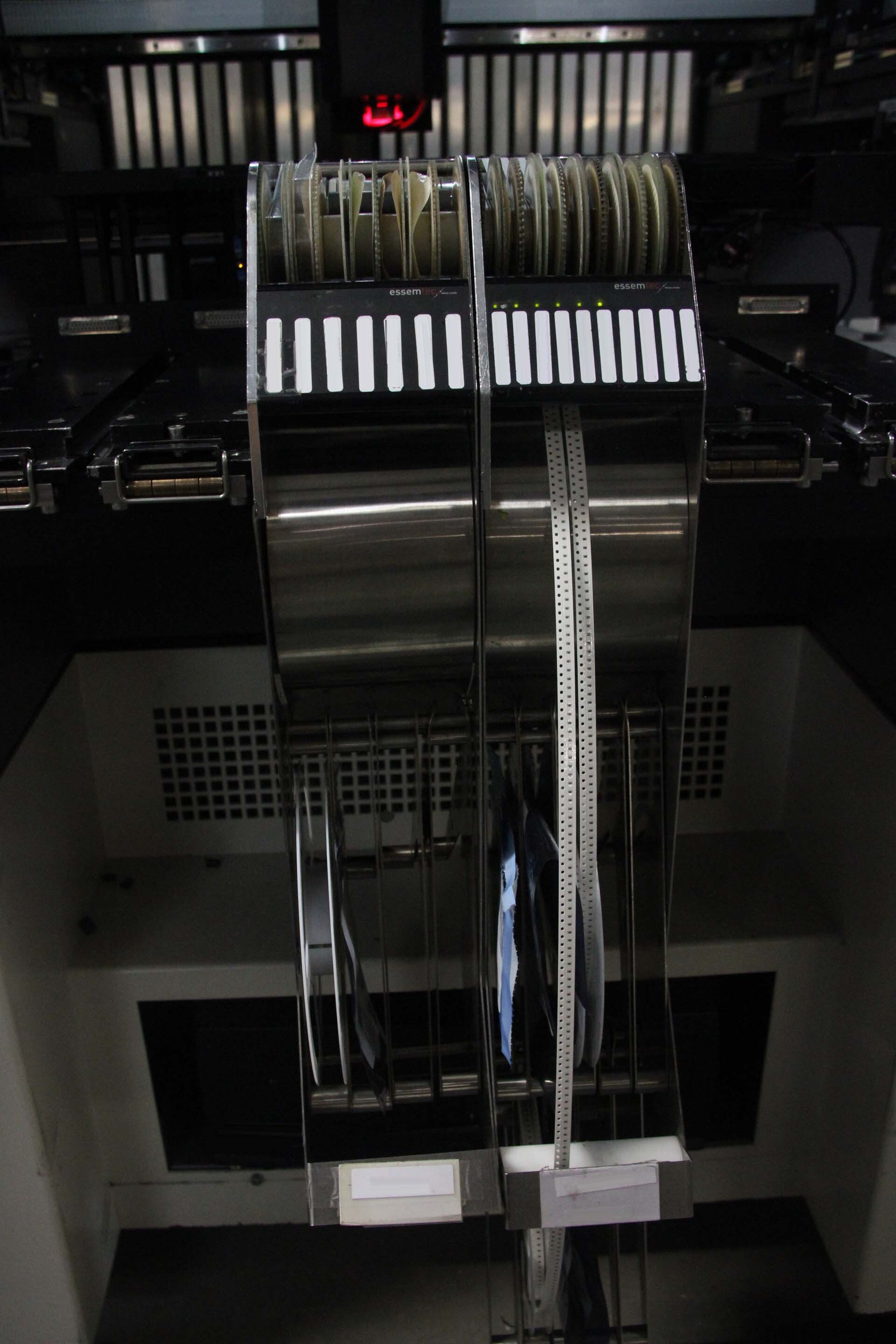

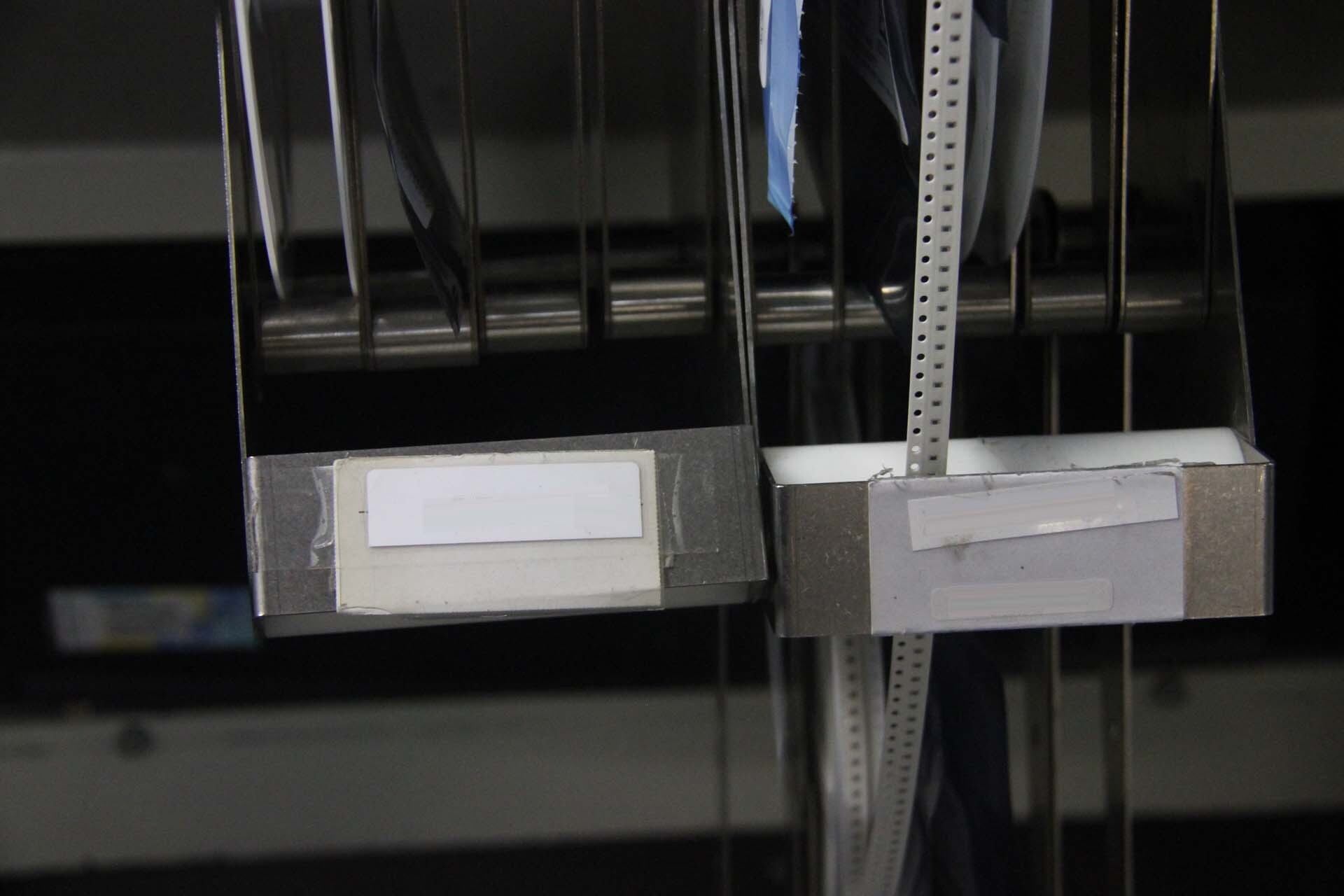

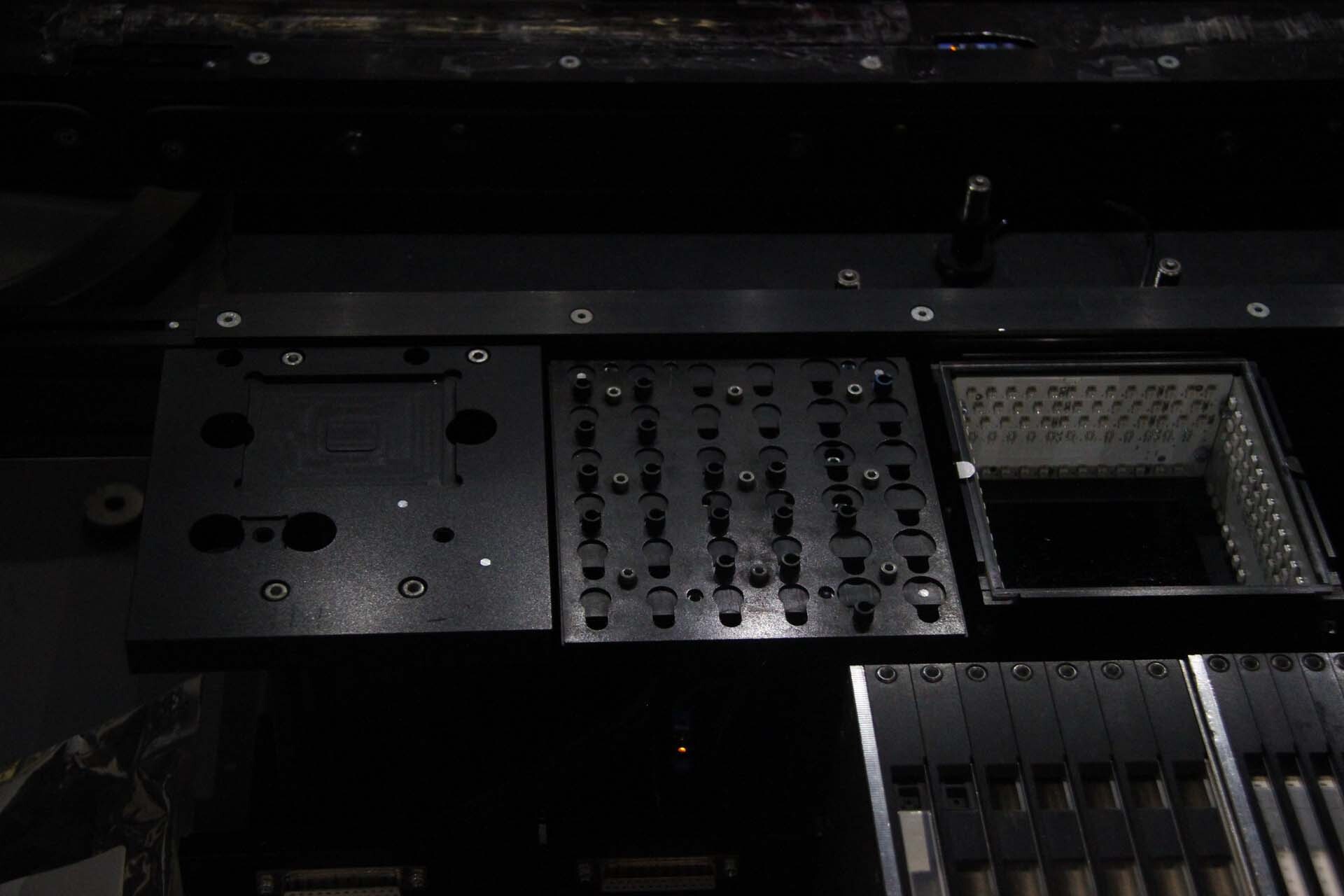

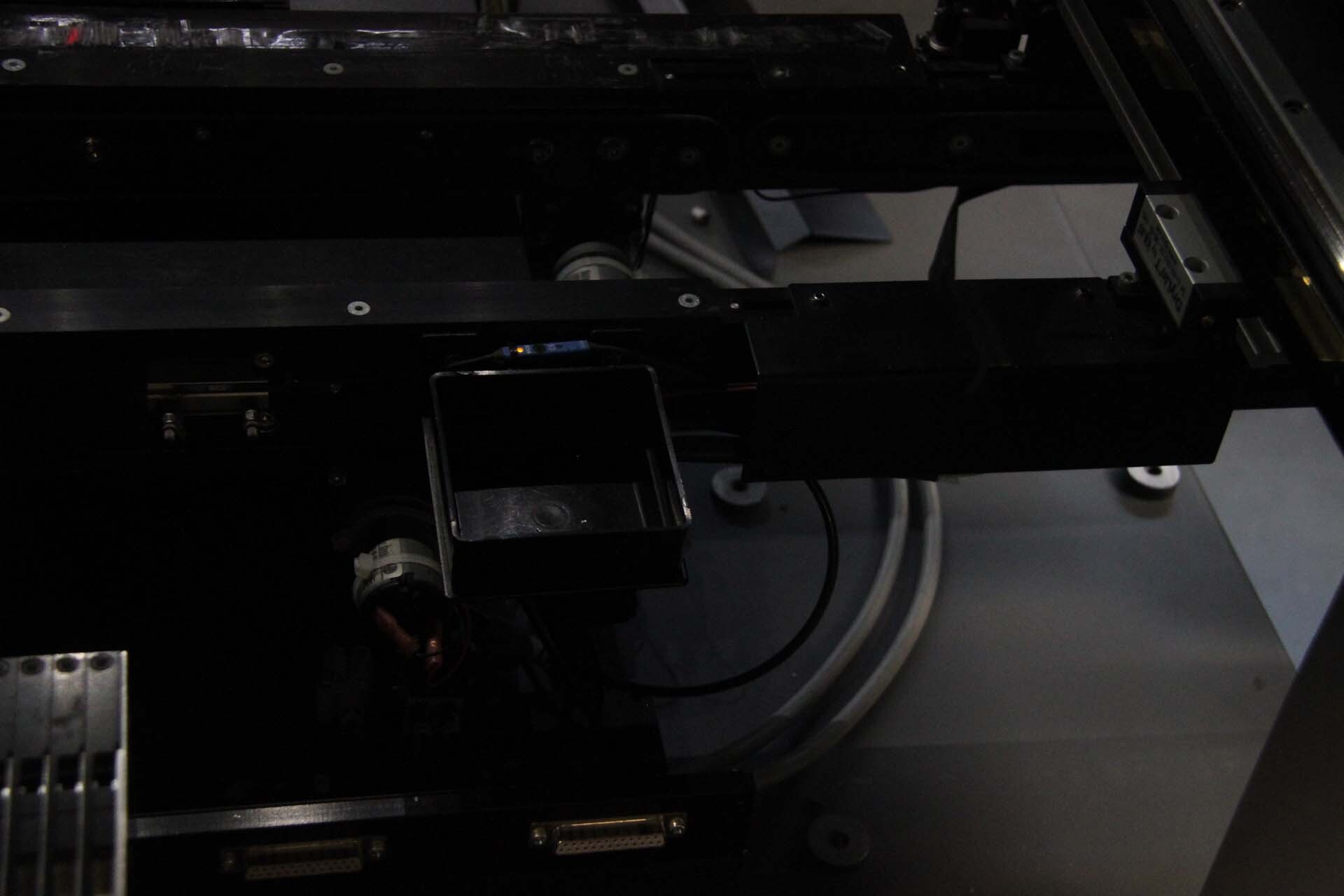

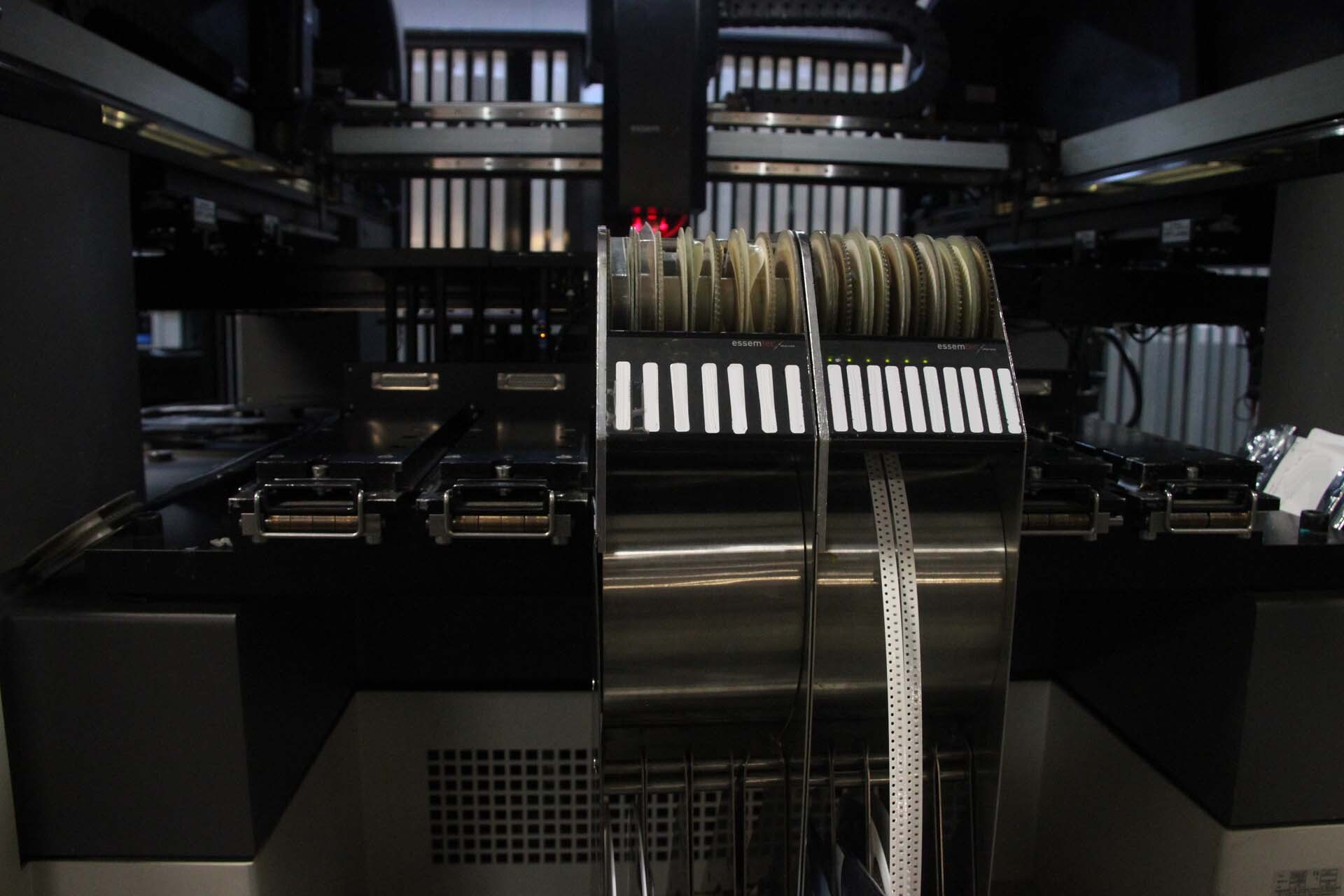

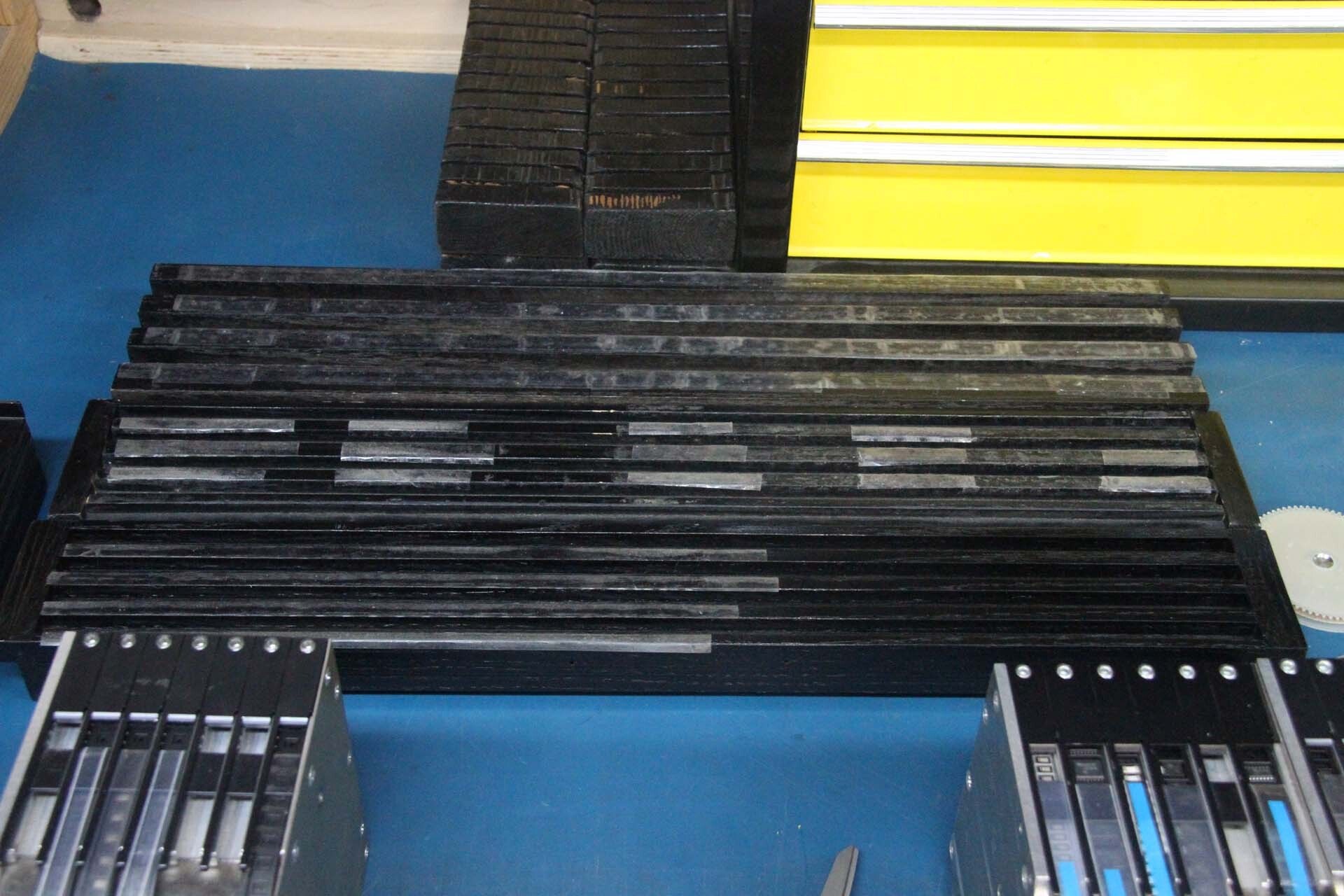

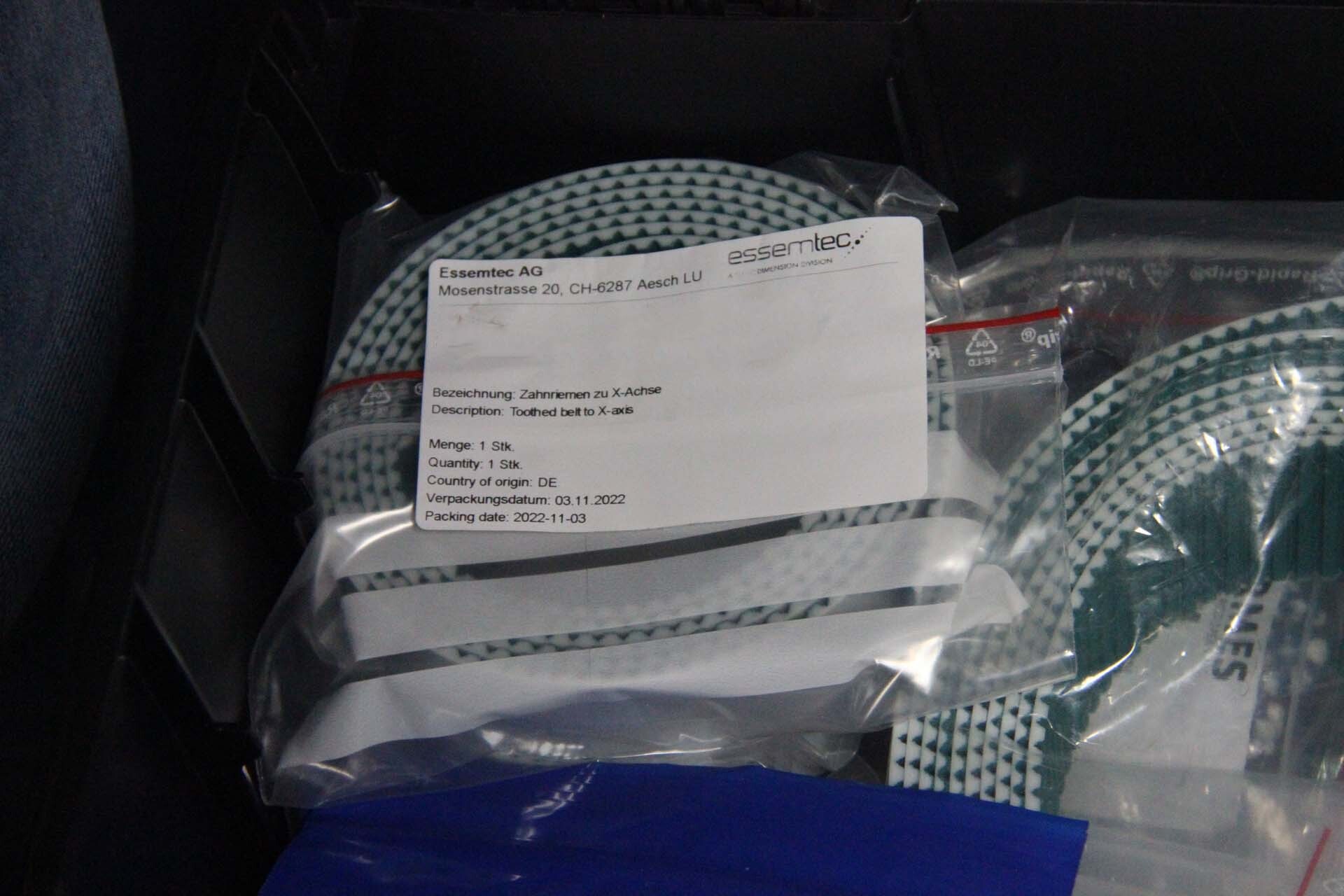

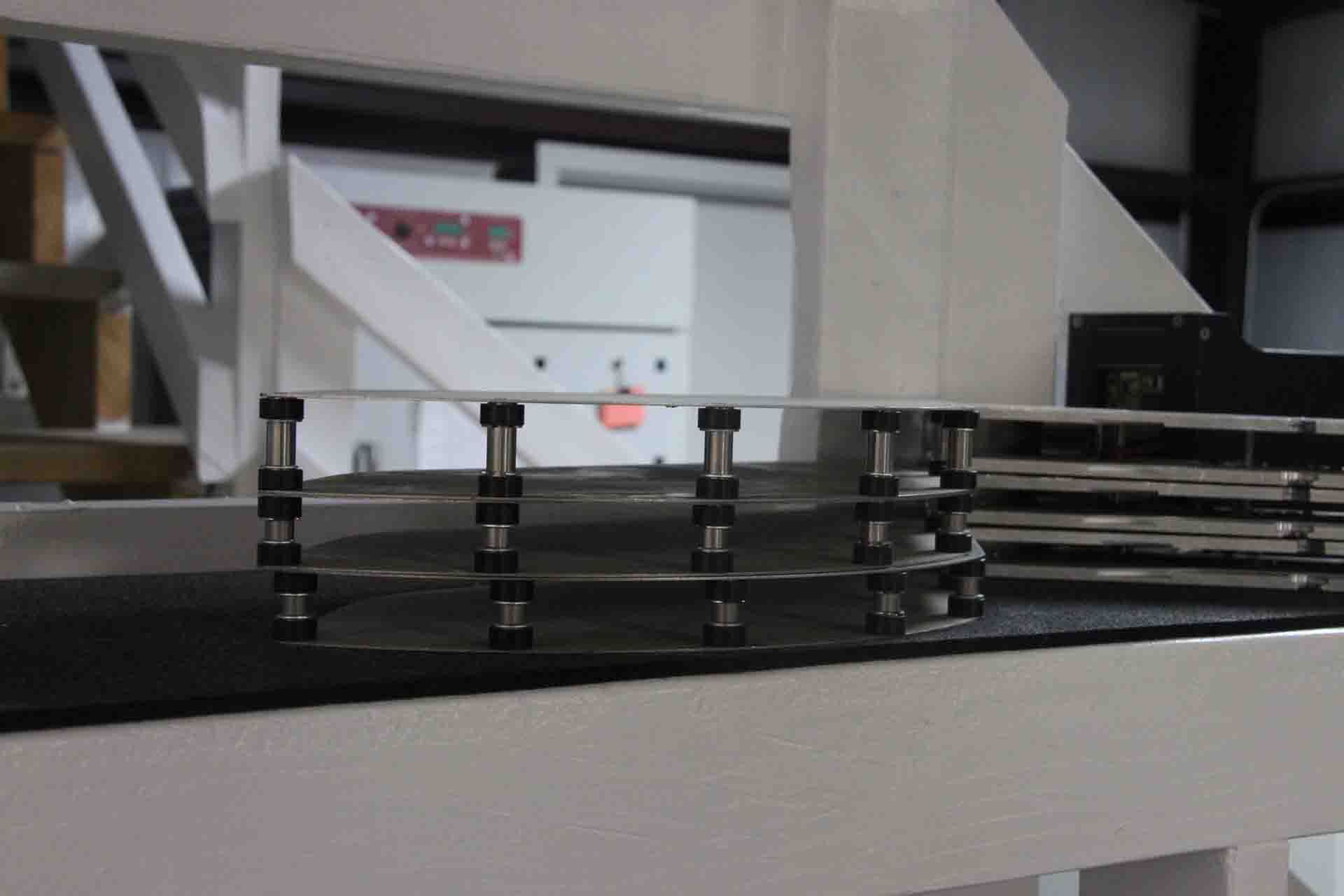

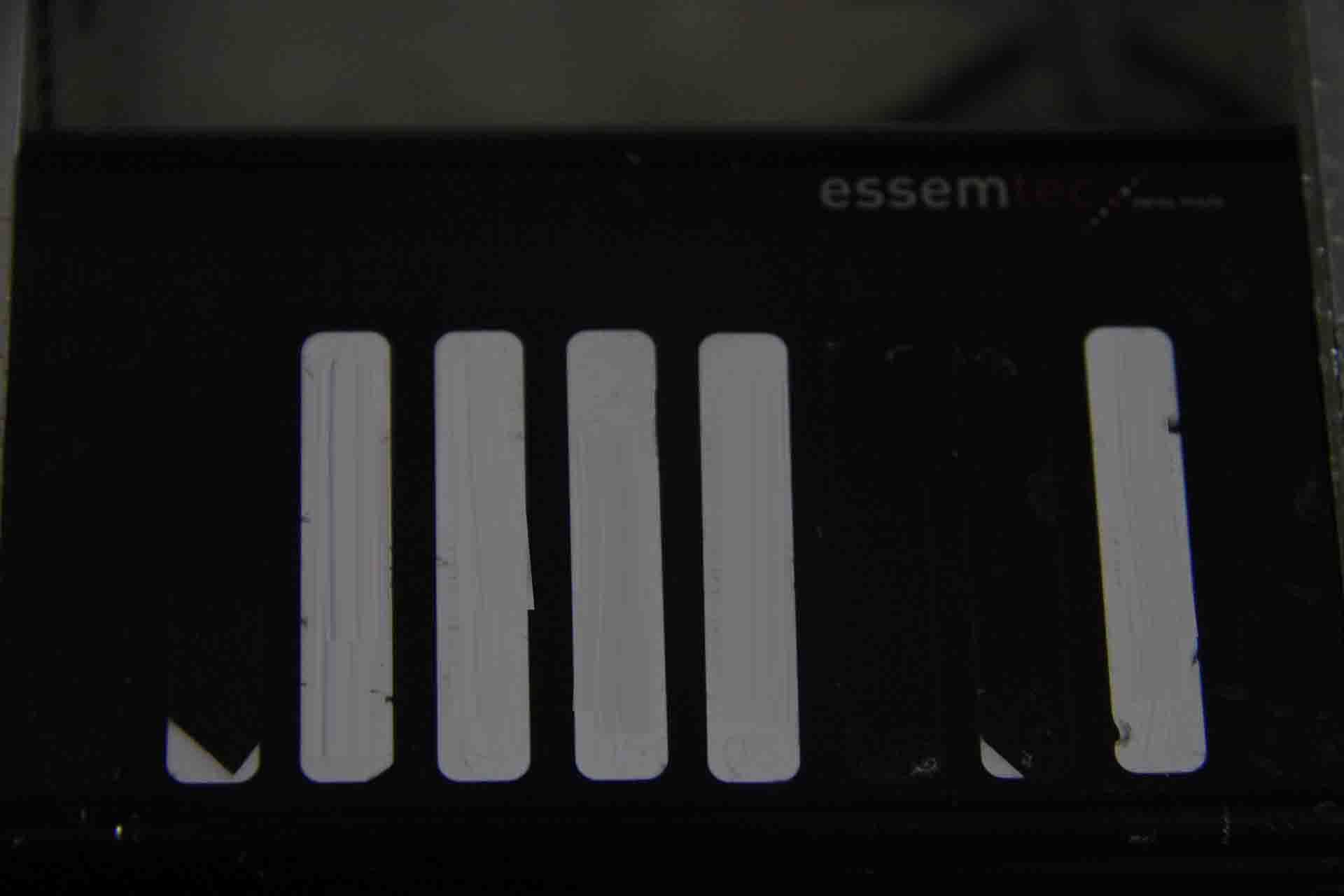

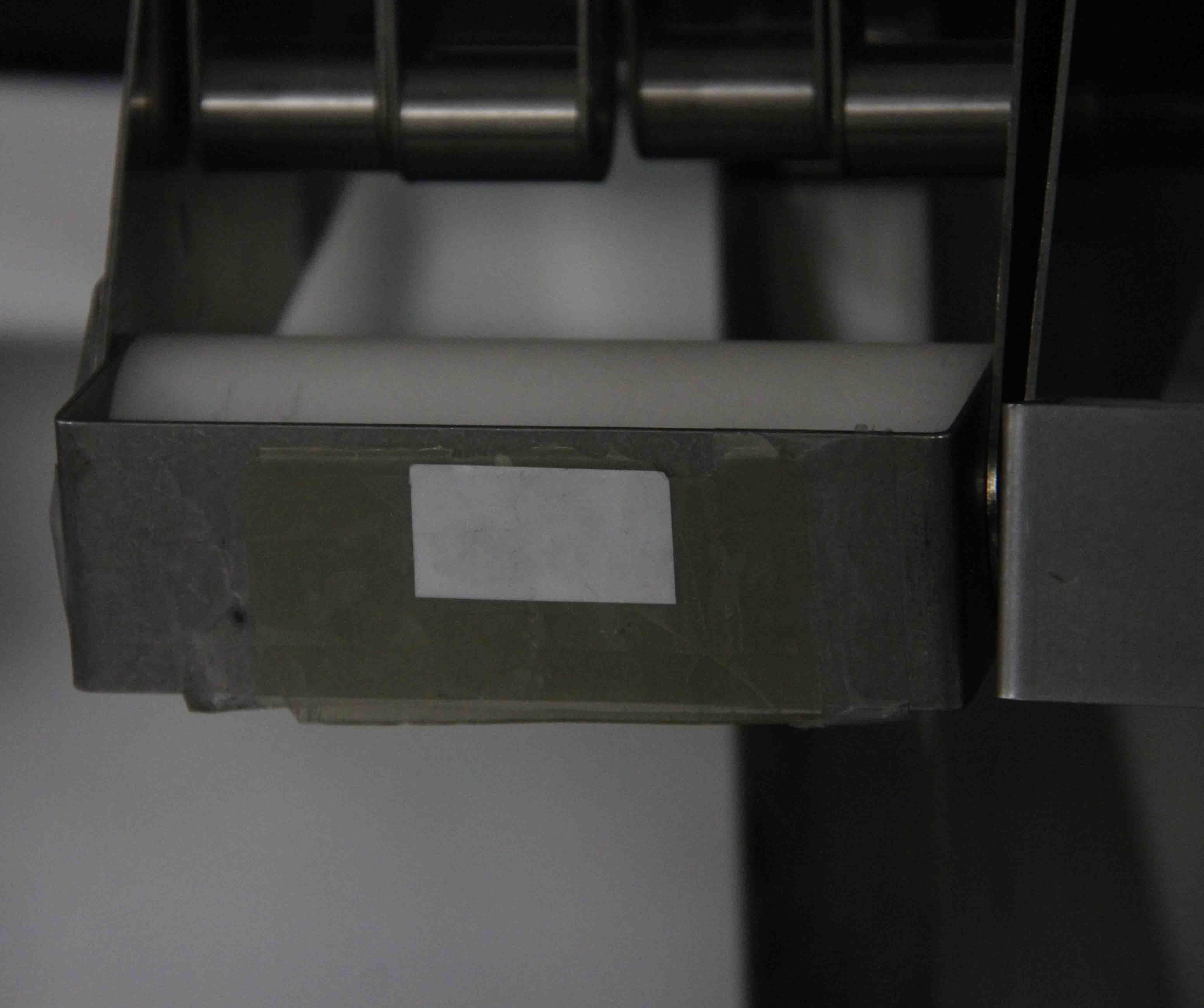

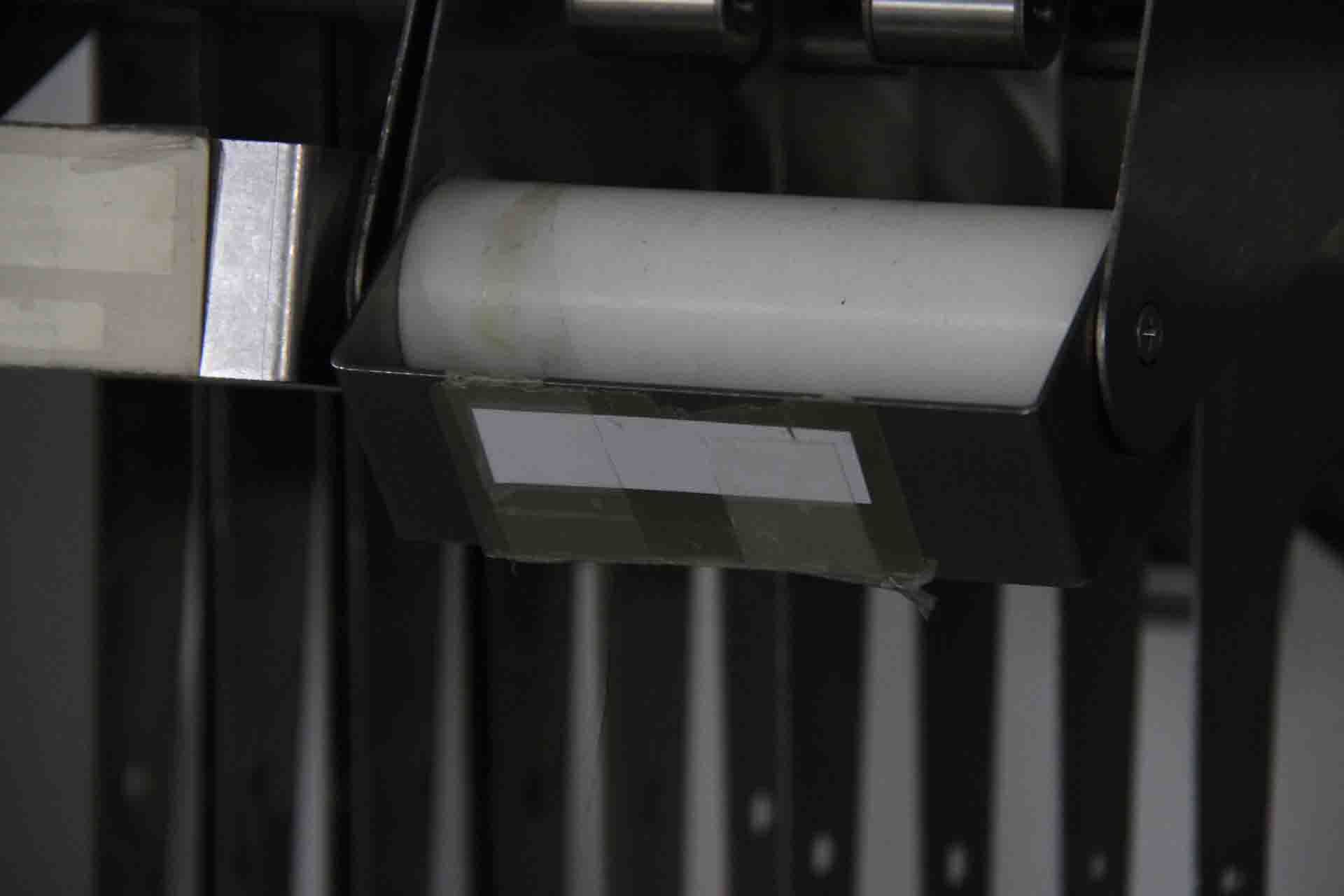

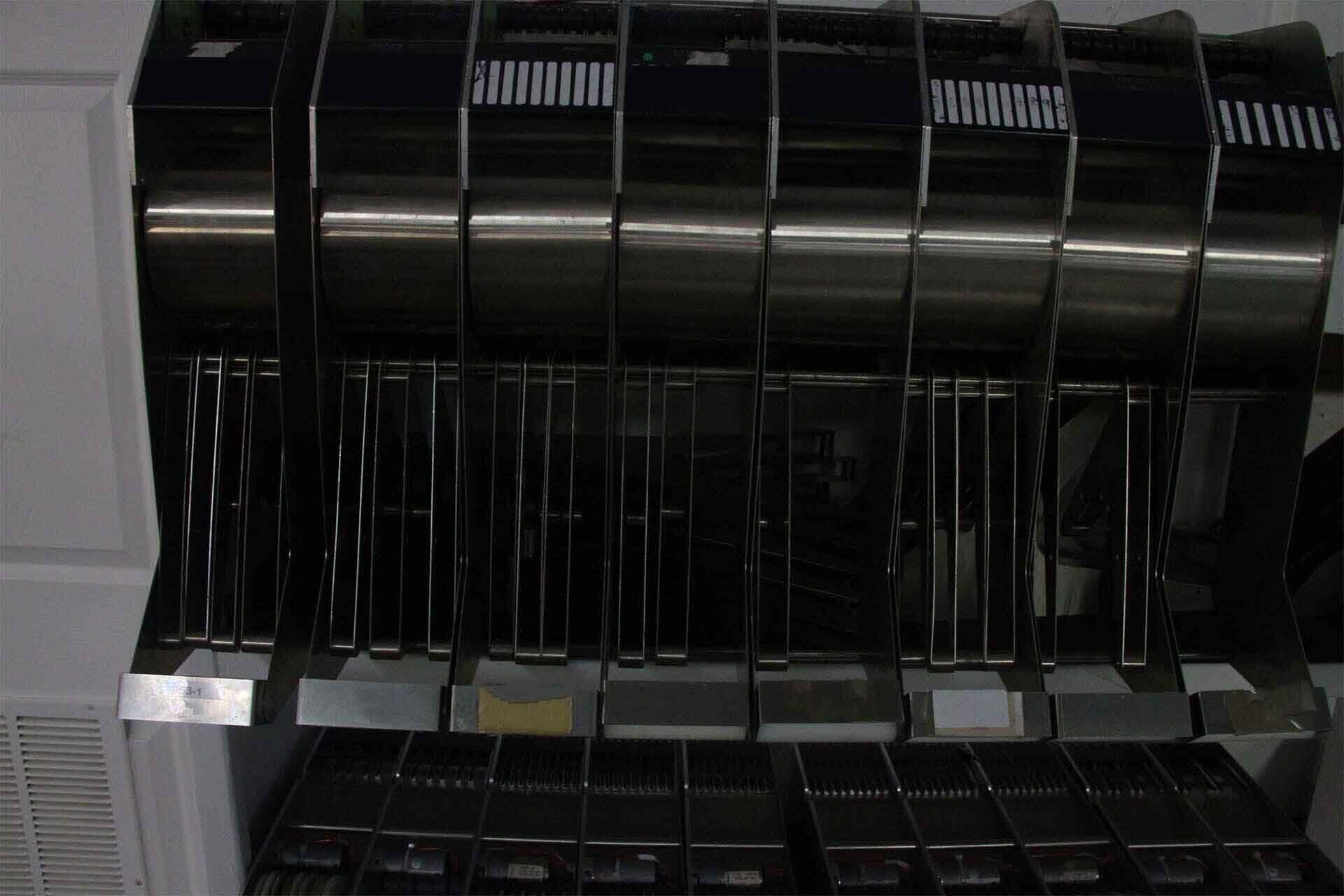

ESSEMTEC Paraquda is a high-tech, automatic, pc board assembly and manufacturing system designed for use in industrial manufacturing processes. It is equipped with a wide array of features that allow for the high throughput, efficiency, accuracy, and repeatability of complex pc board assembly operations. Paraquda is a complete pick-and-place solution that features a variety of independent main components. These components include a front-end controller, a component placement head, a component feeder, a component verification unit, and an X/Y robot. These components work together to ensure that the component placement and assembly process is as accurate and efficient as possible. The front-end controller is a computerized system that programmatically receives component data and tells the component placement head, component feeder, component verifier and X/Y robot what to do. This unit is equipped with a graphical HMI (Human-Machine Interface) that provides the operator with visual feedback and result data on the overall process performance. The component placement head is a high-precision machine that is able to accurately place components on a pc board within an extremely high degree of accuracy. The head is also able to detect errors and faults such as missing components and misaligned parts. The component feeder is a device that enables ESSEMTEC Paraquda to accurately pick components from a specified storage location and transport them to the placement head. This prevents any erroneous placement of parts due to faulty storage or transportation processes. The component verification unit ensures the accuracy of the placement process. This feature analyzes the placement and orientation of components on the pc board for any errors and sends a signal to the front-end controller for any corrective action. Finally, the X/Y robot is a robot designed to manipulate parts in an X/Y axis. This unit is used to quickly and accurately move components to their required location. This allows for a large amount of parts to be placed in a much shorter time period than manual placement. Overall, Paraquda is a high-tech, automated system designed to offer reliable, accurate, fast pc board assembly and manufacturing. It is equipped with a variety of components and features that ensure precision, speed, and efficiency. This offers manufacturers a much more efficient and cost effective approach to pc board assembly and manufacturing.

There are no reviews yet