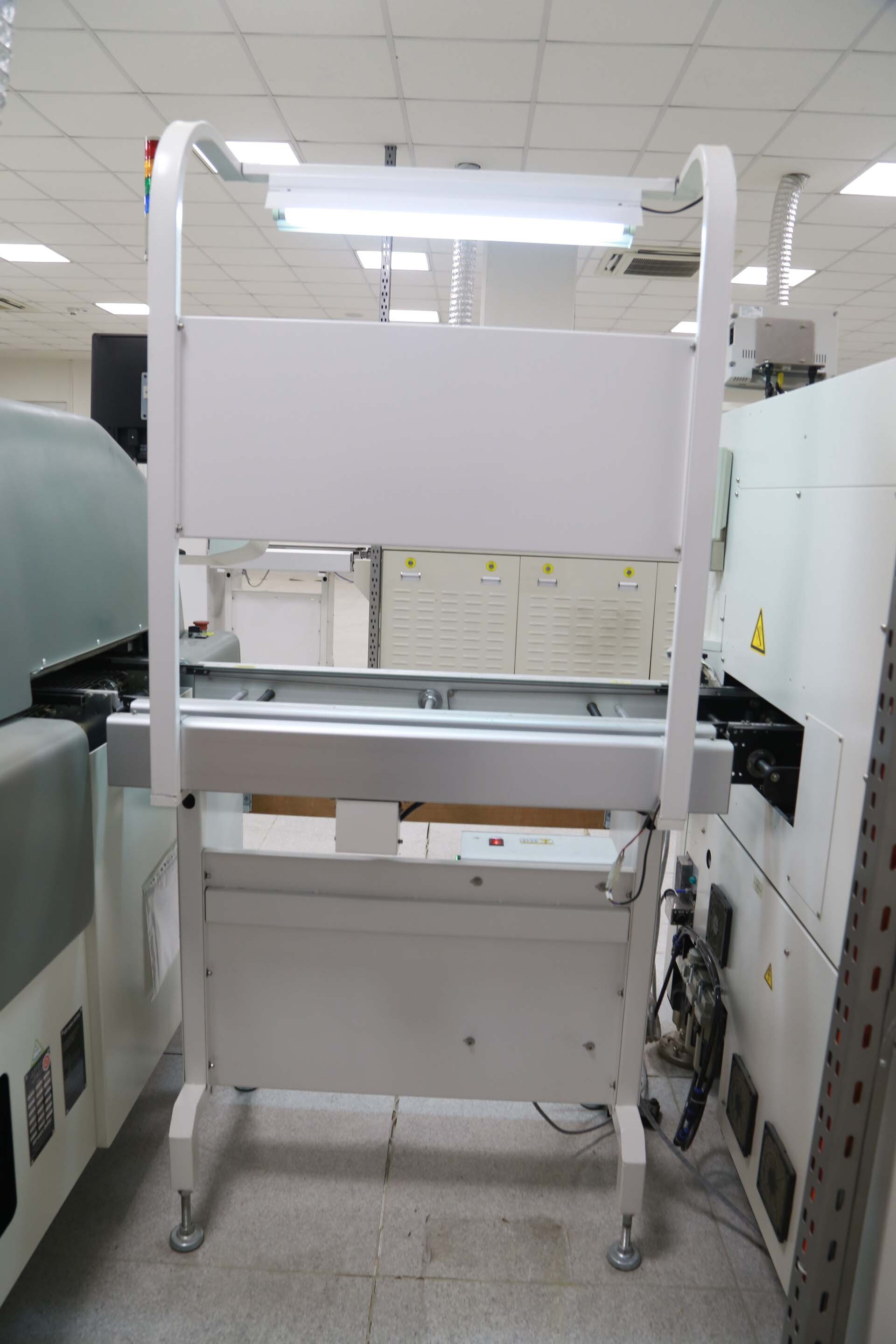

Used EUNOMY EPTC-350 #9407718 for sale

URL successfully copied!

Tap to zoom

EUNOMY EPTC-350 is a powerful, multi-function PC board assembly and manufacturing equipment. The system combines the latest advances in computer vision technology with a fully-automated PC board assembly and finishing process to provide precision assembly and production. The unit consists of an integrated machine controller, vision inspection machine, conveyor tool, robotic assembly, and automated finishing processes. The advanced machine controller includes an embedded real time operating asset, integrated vision model, and Ethernet network connectivity, allowing PC board components to be placed accurately on the target PC board. The high performance vision equipment is capable of recognizing small parts and accurately placing them on the PC board, which allows for greater accuracy and shorter cycle times. The integrated conveyor system is designed to transfer the completed PC boards to the robotic assembly and finishing units. The robots are capable of handling a variety of assembly and manufacturing operations, including surface-mount technology (SMT), through-hole components, and more. In addition, the robotic assembly and finishing processes are capable of self-correction if any unexpected issues arise during production. EPTC-350 features an automated trimmer that ensures precise and uniform cuts, as well as a high precision laser cleaner to remove dust, debris and debris on the PC board. The unit is designed to improve the effectiveness of PCB production by providing high accuracy, high speed and low consumption of materials. In addition, the machine is equipped with a user-friendly interface, which allows users to perform troubleshooting, monitor production status, and adjust operating parameters from a distance. This intuitive tool makes the entire process simple and efficient, while ensuring consistent and repeatable results. Overall, EUNOMY EPTC-350 is an efficient and highly accurate PC board assembly and manufacturing asset that provides the level of production required for today's high-end PCB assemblies. This model is designed with the capability to meet the demands of high-end PCB production, while providing users with enhanced productivity, cost savings, and improved quality assurance.

There are no reviews yet