Used EUROPLACER iineo 2T #9262714 for sale

URL successfully copied!

Tap to zoom

ID: 9262714

Vintage: 2013

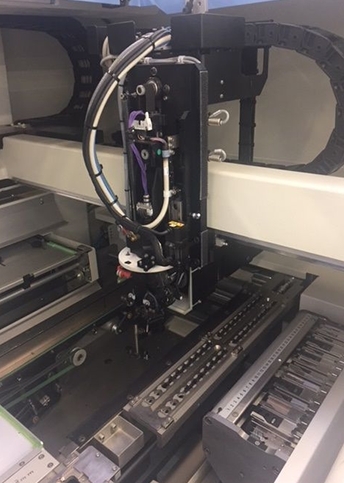

Pick and place machine

Working hours: 21,239

Specifications:

Standard in line conveyor

PCB Dimensions (L x L): 700 x 460 mm (Extended conveyor)

Motorization of conveyor with width adjustment

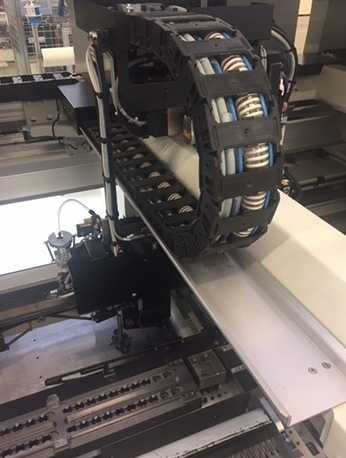

Dual X-Y placement gantry on linear motor

(2) High speed turret placement heads

With global Z and theta axis movement

Board CCD camera: PCB Fiducial / Self teach CCD digital camera

Component CCD camera

(8) Turret nozzles / Maximum component height: 34 mm

(12) Turret nozzles tornado / Maximum component height: 31 mm

Component range: 01005 to 50 x 50 mm

Fixed camera

Vacuum verification system

Optical component presence sensor

Integral vacuum generator

Magazine (40) position nozzles (Without nozzle)

Magazine (60) position nozzles (Without nozzle)

Trolley clamp adapter

Integrated PC Pentium computer and double flat screen monitor

Operating system: Windows 7

Manuals included

Power supply: 400 Volts (3P+N+T)

Air supply: 6 Bars

Color: RAL9002

2013 vintage.

EUROPLACER iineo 2T is a PC board assembly and manufacturing equipment designed to offer small to medium-scale manufacturers the advanced precision technology and productivity enhancements they need. The system is designed to be highly adaptive and reliable with minimal maintenance requirements. Iineo 2T uses high-resolution, high-accuracy imaging to simplify placement accuracy and speed up production times. It features a double-sided 8-zone heating unit with up to 12 soldering heaters for fast, consistent results. The soldering platform can accommodate up to 25 component types and uses advanced dynamic programming techniques for rapid placement on board arrays. The machine utilizes a scanning tool that can detect component and board skew during the placement cycle to adjust placement parameters for maximum accuracy. The asset also features top-of-the-line PC board assembly and software features. It is capable of producing boards with a variety of materials and substrate types including high-density, fine-pitch, and mixed technology assemblies. A unique vision model, including cameras and lighting, enables EUROPLACER iineo 2T to accurately measure and detect components, both identifying defects and ensuring they are placed correctly. In addition, the equipment is compatible with EUROPLACER unique variety of stemless nozzles, simplifying quick changeover and component placement flexibility. The system also includes a wide range of automated material handling options to streamline a variety of production processes. Automated Tape and Reel Feeders and placement sequence calculation enable quick, accurate material feed and placement on complex assemblies. The Integrated Electronics Smart Stores and Cartesian Unit Cartridges provide efficient and integrated inventory management and storage. In addition, the machine includes various speed and accuracy options for configurable operation based on specific requirements. Iineo 2T includes a wide range of features, making it ideal for PC board assembly and manufacturing requirements. It offers the highest precision levels, rapid cycle times, improved reliability, and compatibility that makes it an ideal solution for any small or medium-scale manufacturer.

There are no reviews yet