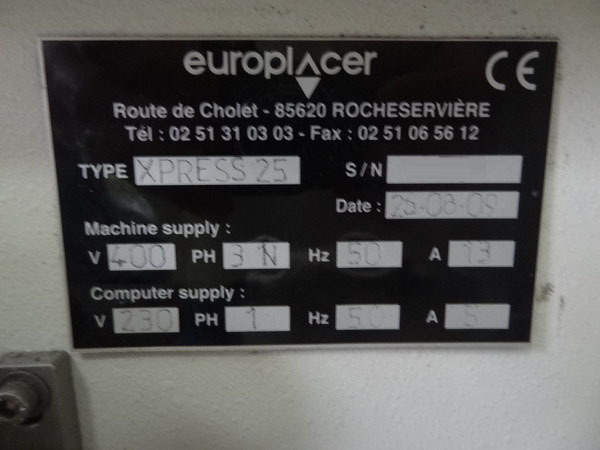

Used EUROPLACER Xpress 25 #9070892 for sale

URL successfully copied!

Tap to zoom

ID: 9070892

Vintage: 2009

Pick and place machine

Hours: 15,500

Speed max: 25,000 cps/h

(2) Heads with (8) nozzles each

(2) Nozzle-changers: (24) positions

(2) Gantry

Digital cameras

Component range from 0201 to 50 x 50 mm (100 mm with fixed camera)

3DPS Sensor

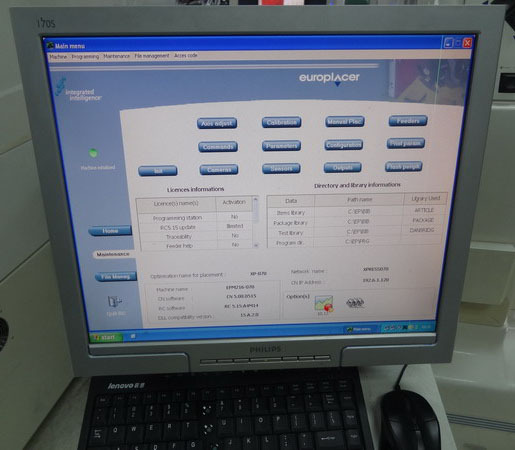

Software: RC5.15

2009 vintage.

EUROPLACER Xpress 25 is a high-performance, low-cost, dedicatedpc board assembly and manufacturing equipment. This small-footprint machineis designed to handle all types of chip packaging, SMT insertion, and leaded component insertion. The system provides excellent flexibility, repeatability, and accuracy; allowing for fast production rates and superior product reliability. Xpress 25 is constructed using an advanced modular design that facilitates component integration. The machine is capable of handling both traditional and advanced chip packaging applications, including 1.27mm pitch BGA, 0.4mm pitch QFN, 0.4/1.2mm pitch SSOP, 0.3mm pitch TSSOP and PLCC packages. This is achieved through the use of an interchangeable chip loader and adjustable, full-speed, high-precision heads optimized for each application. Additionally, EUROPLACER Xpress 25 features a high-accuracy pick-and-place unit that enables fast placement of through-hole components with high yields and placement accuracy. For PCB assembly, Xpress 25 has a multi-headed SMT placement machine capable of placing a wide variety of components, including SOIC, QFN, QFP, BGA, and other lead-less devices, in both standard and leadframe-based packages. The machine also features a precision, automated component vision tool that quickly identifies component package types and inspects parts for quality assurance. Additionally, the machine is capable of processing a variety of adhesives and encapsulants. For manufacturing, EUROPLACER Xpress 25 is outfitted with a powerful test station that can be configured for a variety of applications. The machine is capable of performing a variety of tests to ensure consistent quality products, including continuity, in-circuit testing, and functional testing. The asset also includes an automatic fault detection algorithm to quickly detect any potential issues prior to shipping. In addition, the model includes an intuitive operator interface with real-time status monitoring and control functionality that enables production to be optimized. Xpress 25 equipment provides an ideal solution for PC board assembly and manufacturing due to its high levels of accuracy, flexibility, and reliability. The system is designed to provide cost-effective, high-speed production, allowing for superior quality PCBs with excellent yields and reliability.

There are no reviews yet