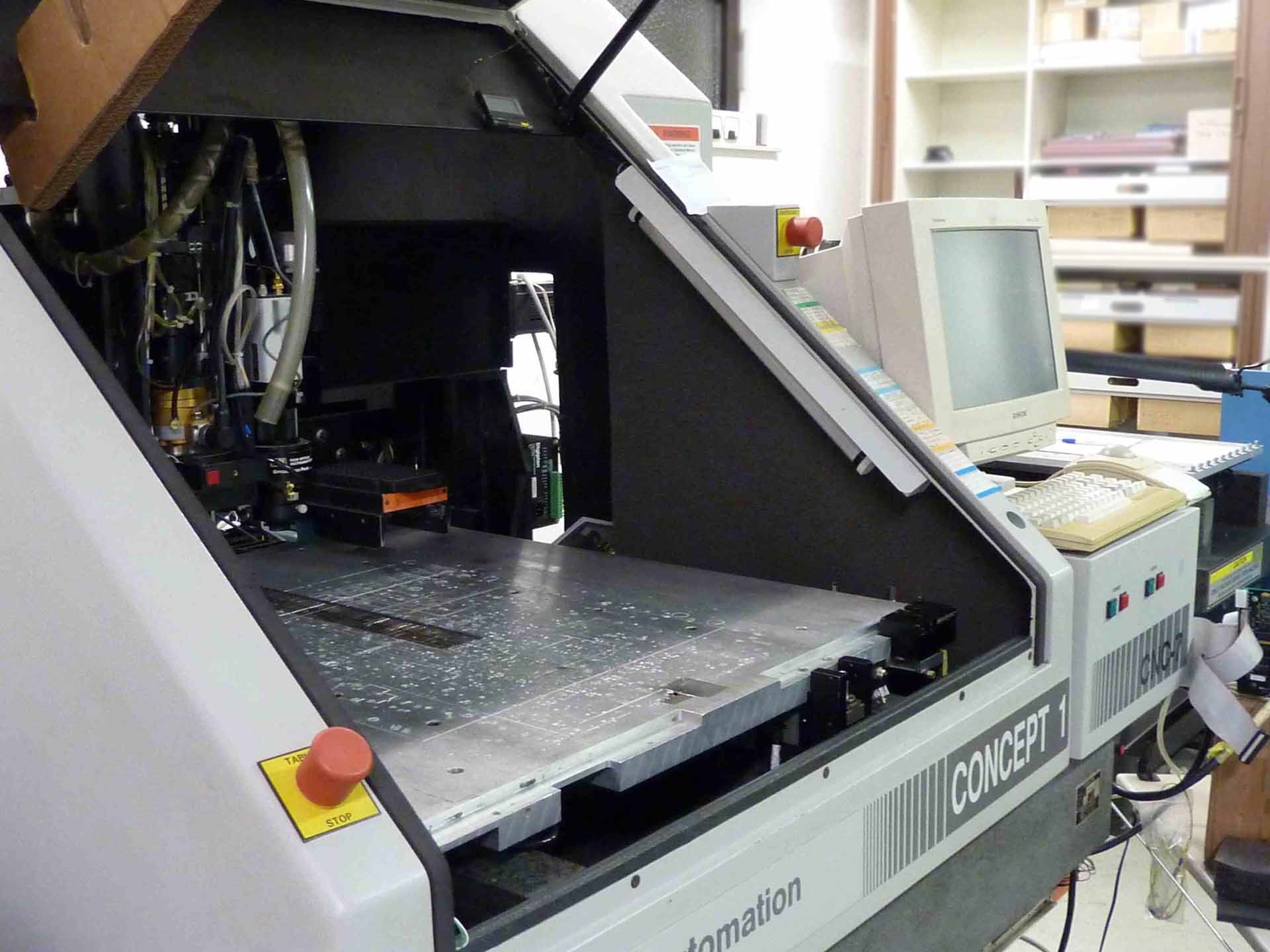

Used EXCELLON Concept One #9219159 for sale

URL successfully copied!

Tap to zoom

ID: 9219159

Drilling machine

Machine base: Fine grain black granite

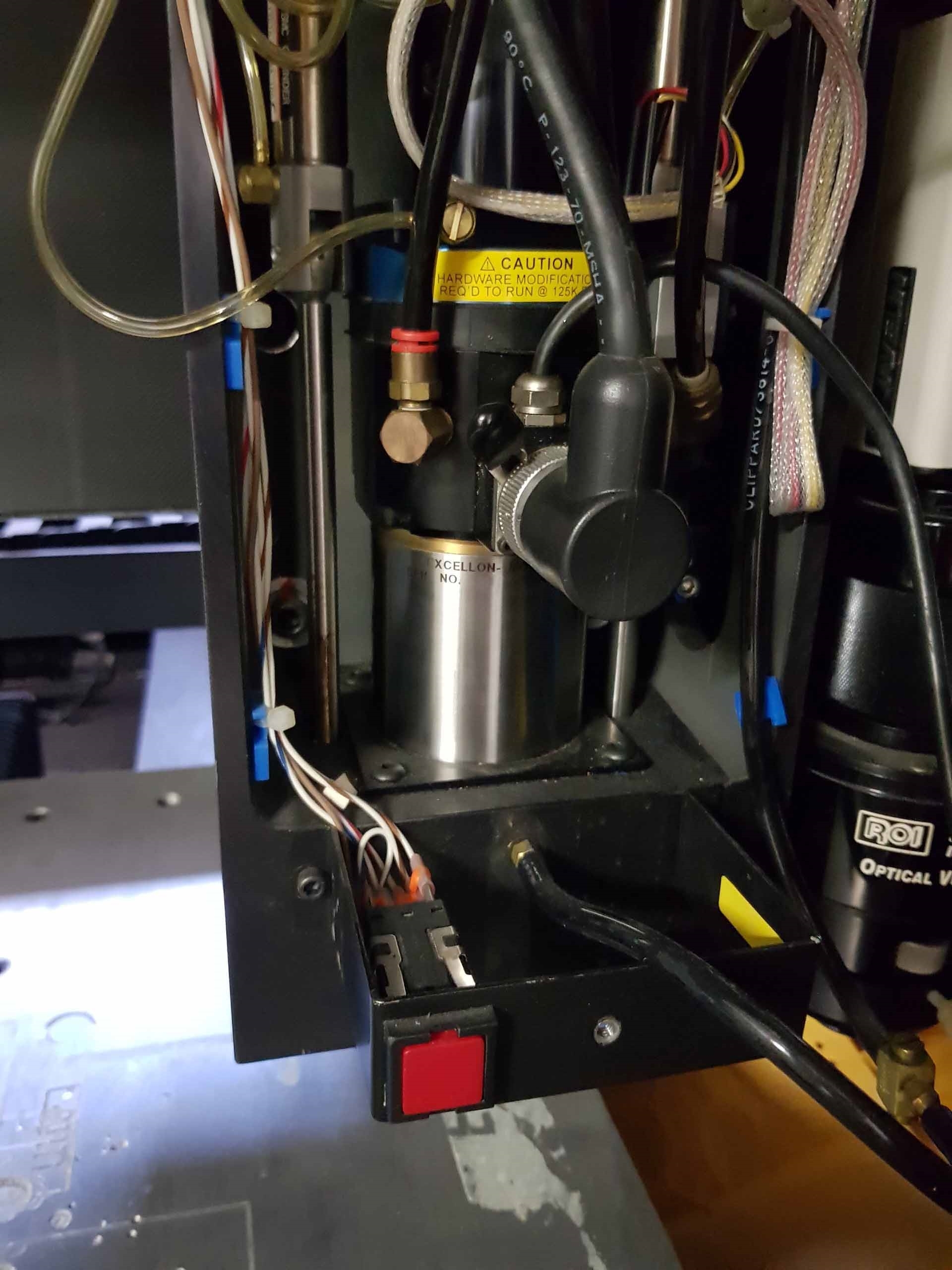

Spindle

Panel size: 32.0" x 32.0" (813mm)

Table guides, bearings and positioning system:

Patented frictionless pre-loaded air bearing

X, Y Guides: Air bearing table flotation

Drill hole accuracy: +/- 0.0007" Typical (0,018mm)

Drill sizes:

0.0039"-0.250" (0.1mm-6.35mm)

Common shank: 1/8" or 3mm

Spindle:

High torque

High speed: 1-HP Air-bearing spindle

Programmable up to 15,000-110,000 RPM

Air-actuated precision collect: 0.125" Standard tool shank diameters

Computer control variable frequency drive

With tachometer feedback control

Closed-loop liquid-cooling system

With heat exchanger

Spindle runout (TK): Typically 0.00012" (3 microns)

Precision Z-axis drive module:

Self-contained precision assembly

Brushless drive

Preloaded leadscrew

Flexure coupling

EXCELLON Air bearing spindle

Depth control accuracy:

Production drilling: +/- 0.002" (+/- 0.05mm)

Total depth tolerance: Measured top of workpiece

Tool management system: 120 Cassette permitting tools

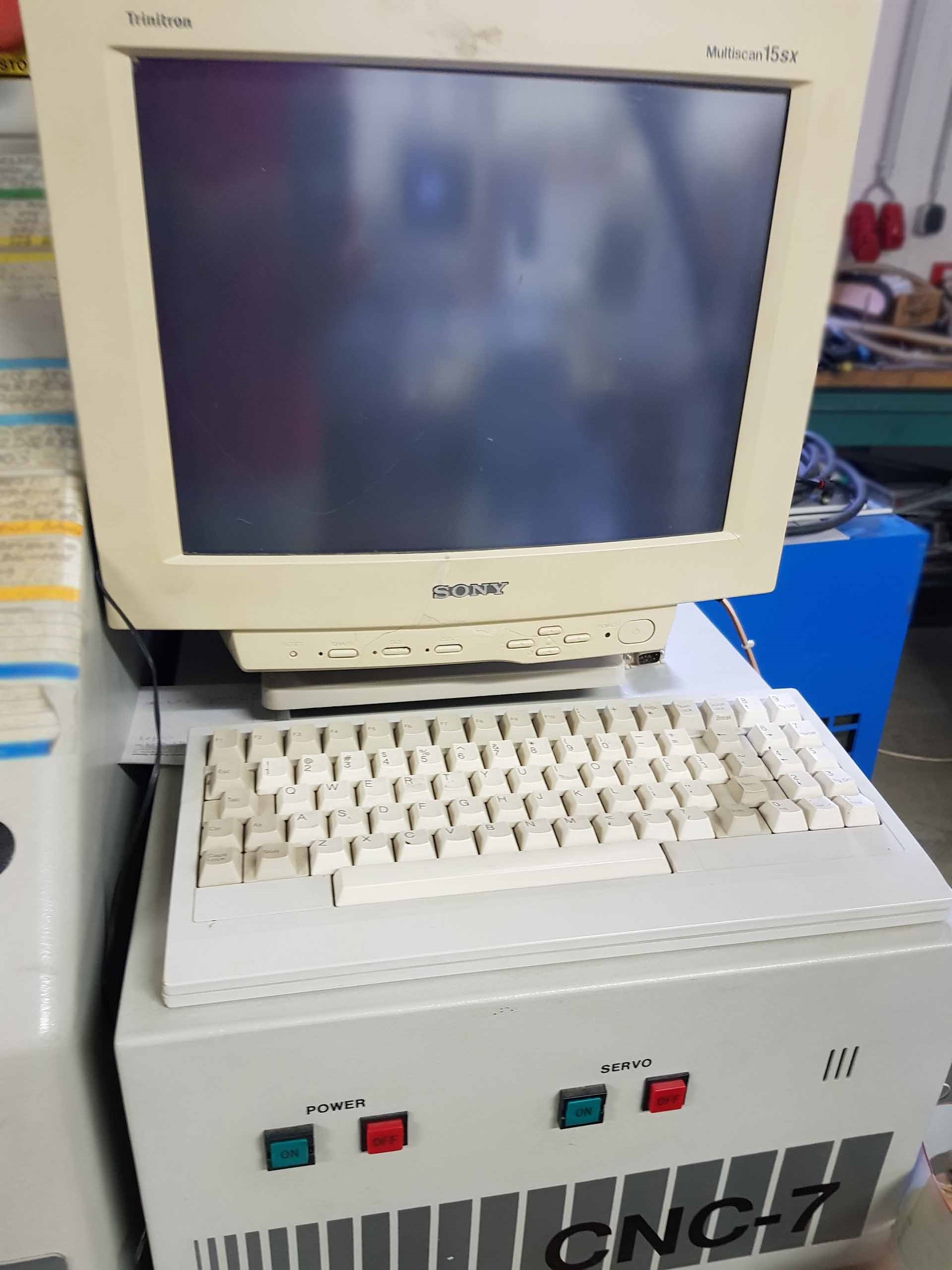

Control system:

EXCELLON CNC-7 Advanced adaptive control

With 32-bit processor

Additional microprocessor for intelligent motion control

1MB Dynamic RAM

20MB Hard disk standard

Data entry:

5 1/4" & 3 1/2" disk

Paper rape

Cassette and DNC options

Air input: 95 to 150 PSI, 20 scfm flow

Power input: 230 V, 50/60 Hz, 20 Amps, 1 Phase.

EXCELLON Concept One is a pc board assembly and manufacturing equipment designed to facilitate easy and automated assembly and manufacturing of pc boards. It is based on an automated board array hand-held drill which can drill up to 48 boards simultaneously, both standard and advanced, in a single pass. The system also includes a module selection which allows the user to select which modules they want to assemble on a board. This feature is ideal for larger scale batch production runs, as the user has the flexibility to select different modules for unique projects. The entire assembly process is guided by the software provided. Using the set-up wizard, data for the board edge connectivity and hole pattern drill specifications are entered into the software for drilling and routing. The grid-centric pattern of the drill ensures accuracy and repeatability. Once the data has been entered in the unit, it then calculates the hole locations based on the information. It will even indicate any potential errors so that the user can adjust and correct them quickly. Another great feature of the machine is the ability to define testable rules that can be applied to the board. This will allow the user to specify their own tolerances and testable rules, ensuring the end-product is always up to the highest quality standards. Once drilling and routing is completed, the board can then be passed to quality control for pass/fail testing. Concept One is extremely quick at implementing boards, as it can quickly set up its tools for varied hole sizes depending on the application. Once the job is complete, the boards are then passed to the programming stage, where pick-and-place, thru-hole insertion, soldering, and other techniques can be applied. This allows for smaller scale manufacturing runs with complex boards and components. Overall, EXCELLON Concept One is an incredibly efficient pc board assembly and manufacturing tool. Its flexibility allows it to be used on both small scale and larger batch projects, and its automated features ensure accuracy and repeatability. With the included testable rules feature, users can be assured that their boards are always of the highest quality. The asset's flexibility and performance make it the perfect choice for a wide variety of pc board assembly and manufacturing needs.

There are no reviews yet