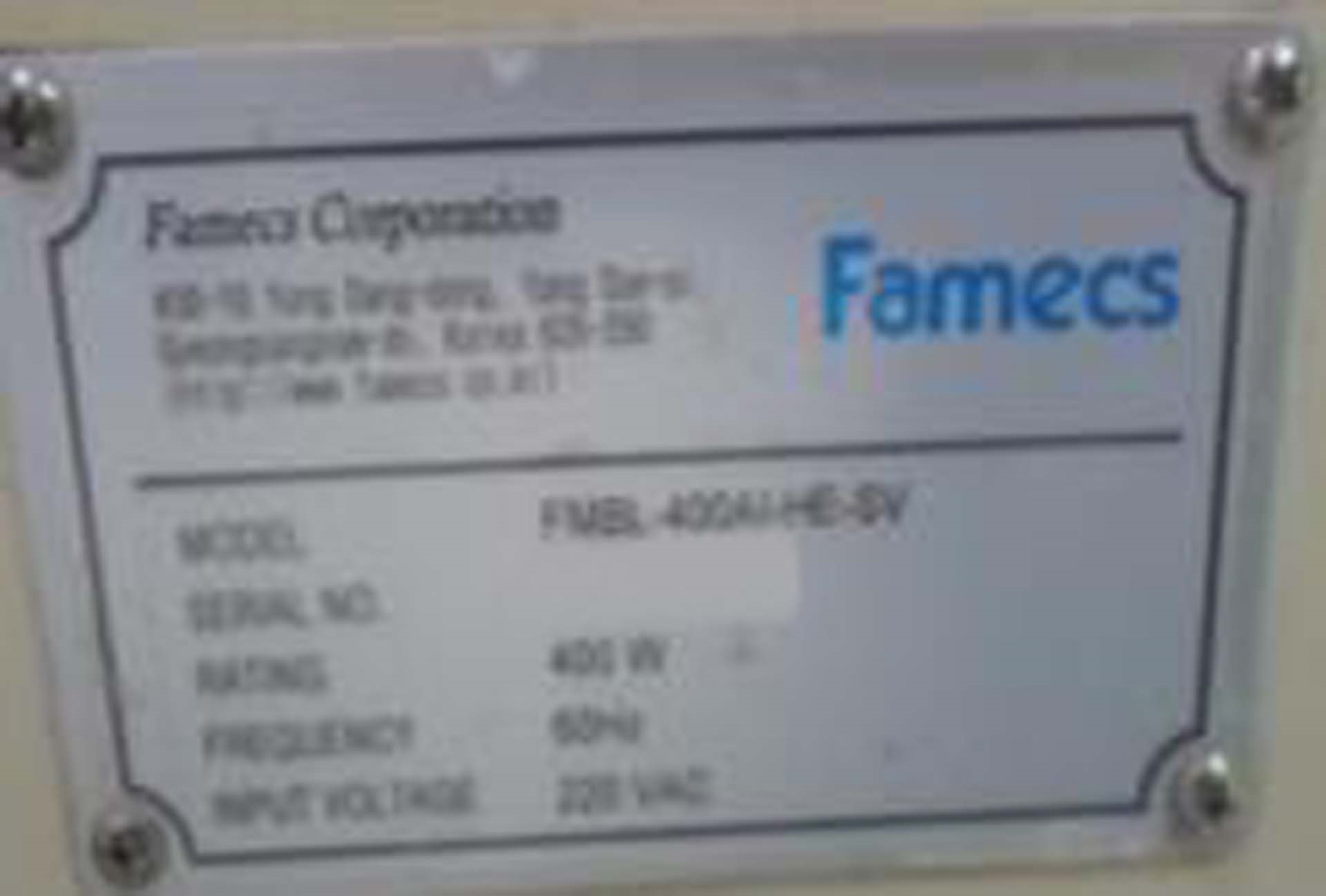

Used FAMECS FMBL-400AI-HE-SV #9255123 for sale

URL successfully copied!

Tap to zoom

FAMECS FMBL-400AI-HE-SV is a high-end PC board assembly and manufacturing equipment featuring an integrated front-end robotic loader/unloader. This system is designed to feed components onto a board in an automated, precise, and consistent manner. It is also designed to be easy to use and highly efficient. The unit consists of an integrated conveyor machine, a reject gate tool, a multiple camera placement asset, and a dynamic tracing model. The conveyor equipment is used to transport printed circuit boards (PCBs) from one station to the next. The reject gate system is used to identify and eliminate any defective PCBs before they reach the camera placement unit. The multiple camera placement machine is used to improve accuracy of component placement as well as to capture images for component identification. Finally, the dynamic tracing tool is used to detect any disruption in component placement. All of these features combine to allow the asset to consistently and accurately fulfill assembly orders. The integrated robotic loader/unloader is able to precisely place components on the boards with high speeds and minimal downtime. This model also performs component identification and verification automatically, allowing for fast, repeatable results. In addition to these features, FMBL-400AI-HE-SV also offers fully customizable software settings. These settings include traceability options, programmable board capacities, and the ability to set optimization parameters. This equipment also provides a graphical user interface (GUI) that allows operators to easily monitor the production process and change settings as needed. This graphical user interface also offers error detection, which allows users to quickly identify any errors that have occurred and take measures to correct them. Overall, FAMECS FMBL-400AI-HE-SV is a highly advanced system for PC board manufacturing and assembly. Its integrated features and customizable software settings make it an effective, efficient, and reliable choice for companies looking to satisfy their production requirements.

There are no reviews yet