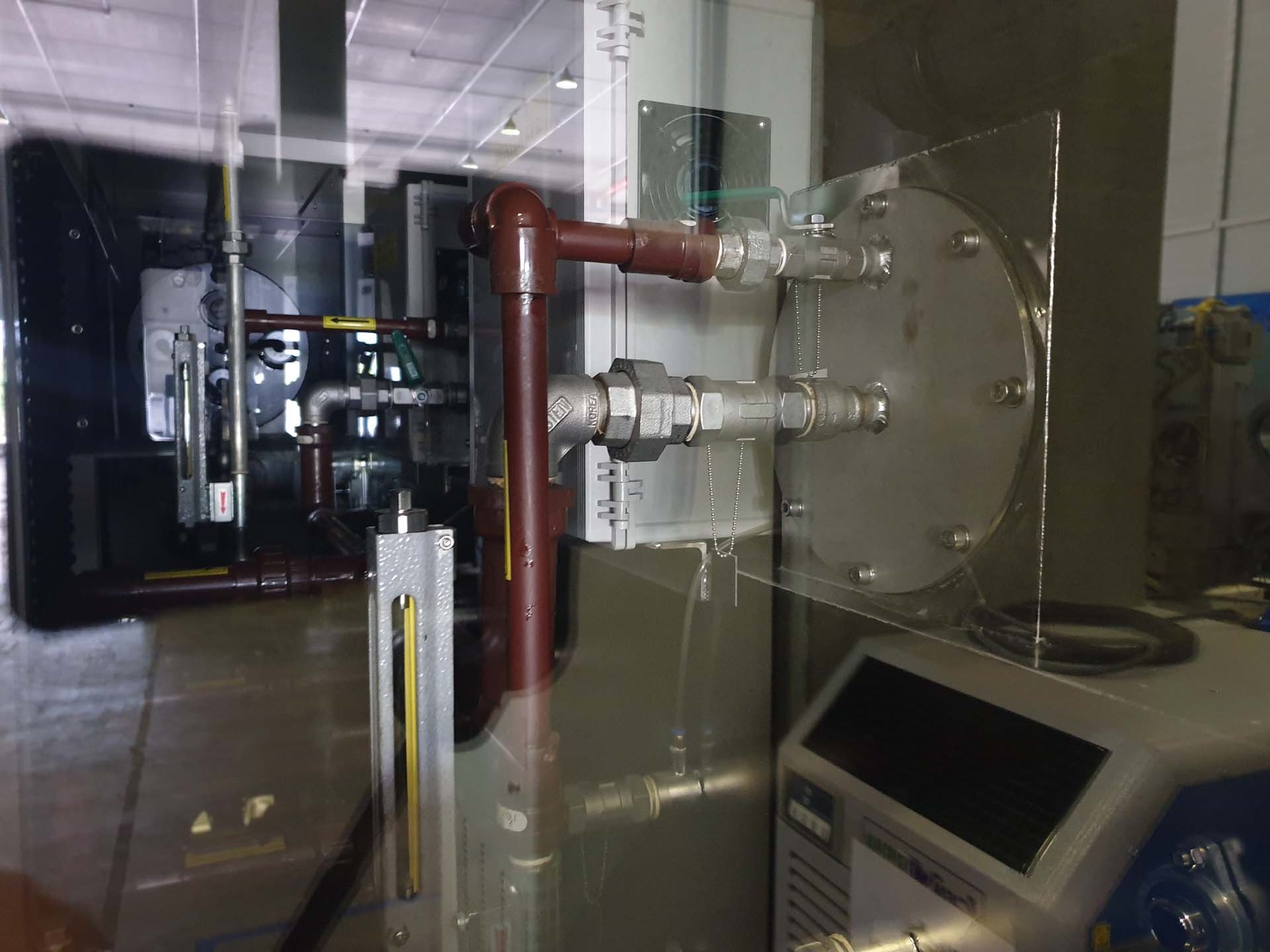

Used FINE CM CPCM-1000 #9241054 for sale

URL successfully copied!

Tap to zoom

FINE CM CPCM-1000 PC Board Assembly and Manufacturing Equipment is an innovative manufacturing and assembly system built to accurately and quickly manufacture and assemble printed circuit boards (PCBs). It is a full production unit that consists of various parts: an automatic PC board loader, an automatic feeder module that contains tools like a soldering robot, a Pick & Place robot, and a toolings robot, a conveyor machine for handling the PCBs in each of the different stages of production, and an automatic electrical inspection module. The manual loading component of the tool allows boards to be loaded and unloaded quickly and accurately. The unique Pick & Place robot allows for precise component placement during the assembly process. The soldering robot provides reliable and consistent soldering performance, which ensures most optimal production conditions. The toolings robot facilitates efficient and accurate production line restocking when it is time to replenish parts. The asset has a built-in conveyor model that links each of the processes and further increases the effectiveness of the production process. This conveyor equipment reduces overhead and increases accuracy by transporting the PCB from one work process to another. Additionally, an automatic electrical inspection module checks for accuracy in electrical components after they are placed on the board. CPCM-1000 system has a user-friendly touch screen panel which provides real-time monitoring of all production processes. The unit also automatically updates a manufacturing database, enabling the user to track their production results. This machine not only increases productivity, but ensures accuracy in a safe and reliable manner. FINE CM CPCM-1000 tool is the perfect choice for mass production of printed circuit boards, providing an innovative manufacturing and assembly asset.

There are no reviews yet