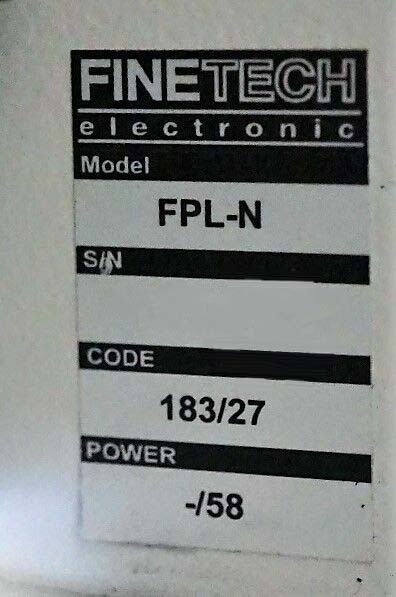

Used FINETECH Fineplacer 183 #9411704 for sale

URL successfully copied!

Tap to zoom

ID: 9411704

Vintage: 2002

Rework station

Type: FPL-N 183-27

Top and bottom heater

Temperature: 360°C to 380°C

Heating gradient: Adjustable between 1 and 50 K/s

Placement accuracy: Less than 10 µm

X and Y Table with control module

Vacuum tweezers

Ambient lighting

PLCC

QFP

SOP

BGA

LEICA MZ6 Stereo microscope

Mirage image splitter with camera

Soldering process: Round carousel

SONY Monitor

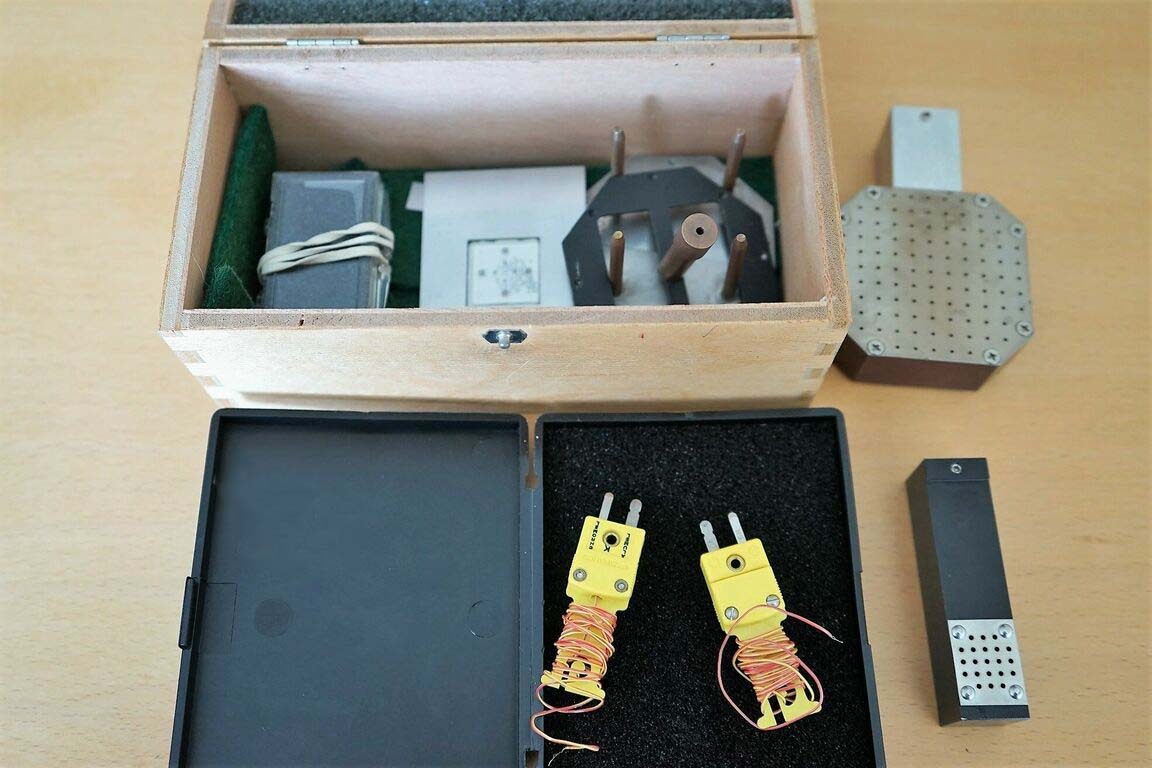

(8) Soldering heads (BGAs, SOPs and QFPs)

(7) Stencils with holders

(2) Temperature sensors

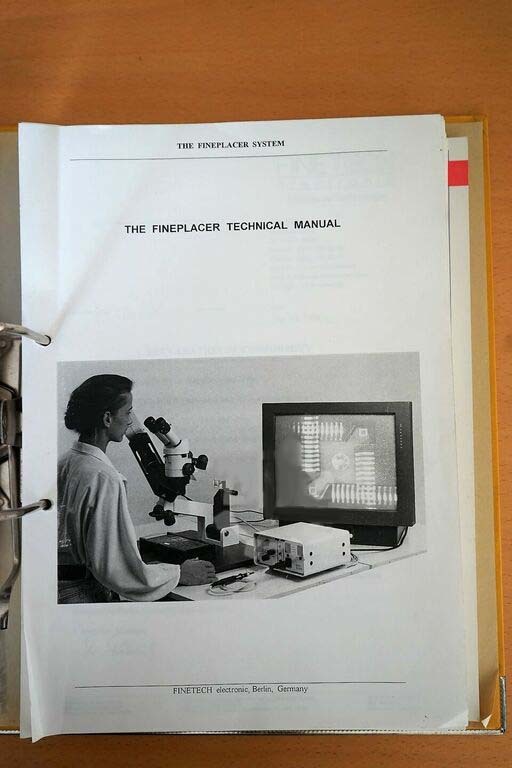

Documentation: Several staples operation and service

SCHNEIDER Medic Air 300-50 Silent compressor

Pressure: 8 Bars

With 50 Liter pressure tank

Construction of circuit board prototypes

COLD BEKO RA3 Refrigeration dryer

PC With Intel x86 Gen 6

500 MB RAM

LCD Monitor

Numerous material: Air piping

4GB Hard Disk Drive (HDD)

Split field optics

Operating system: MS-DOS

2002 vintage.

FINETECH Fineplacer 183 is a PC board assembly and manufacturing equipment that offers the ideal tool for low to medium-volume, highly complex production runs. This system is extremely versatile and covers all aspects of modern electronic production. Fineplacer 183 can be used to place and solder components of different sizes and types, including surface mount and through-hole components. It has modular components and a flexible configuration so it can be customized to match production needs. The lightweight, portable unit comes with a high-resolution monitor, a touch-screen, and separate input and output terminals to allow for easy set-up and adjustment. FINETECH Fineplacer 183 has a X/Y/Z movement of 1.300 x 850 x 200 mm, a maximum board size of 610 x 678 mm, and a positioning accuracy of +/- 3 microns. To ensure accuracy, the machine is equipped with a digital vision unit, a high-speed/high-precision camera, a dead-zone optimization algorithm, and advanced 3D placement software. The machine is capable of laser centering for precise positioning, dual-vision alignment for even higher accuracy, and single vision alignment for cost-efficient production. Fineplacer 183 offers an integrated high-precision soldering tool for eutectic, wave and selective soldering. It's also equipped with an intelligent process control asset with machine-learning algorithms that can be used to control and monitor production parameters. The soldering process can be monitored in real-time through a touchscreen user interface and can be fine-tuned when necessary. The model also has a variety of different mounting capabilities, allowing it to accommodate a range of components. Its sophisticated handling equipment can pick up components ranging from 0402 to 40 mm in size and of any weight. The system also offers a broad range of programming options to accommodate different components and specific production requirements. FINETECH Fineplacer 183 is the perfect solution for companies that require a robust, versatile unit for their PC board assembly and manufacturing. It's fast, efficient, and cost-effective, and provides highly accurate results. It's the ideal solution for complex production tasks.

There are no reviews yet