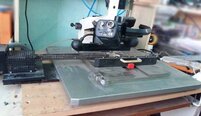

Used FINETECH Fineplacer #9302646 for sale

URL successfully copied!

Tap to zoom

ID: 9302646

Rework station

With LEICA microscope

Comerson camera

HP Pentium IV with DVD ROM drive

Placer controller

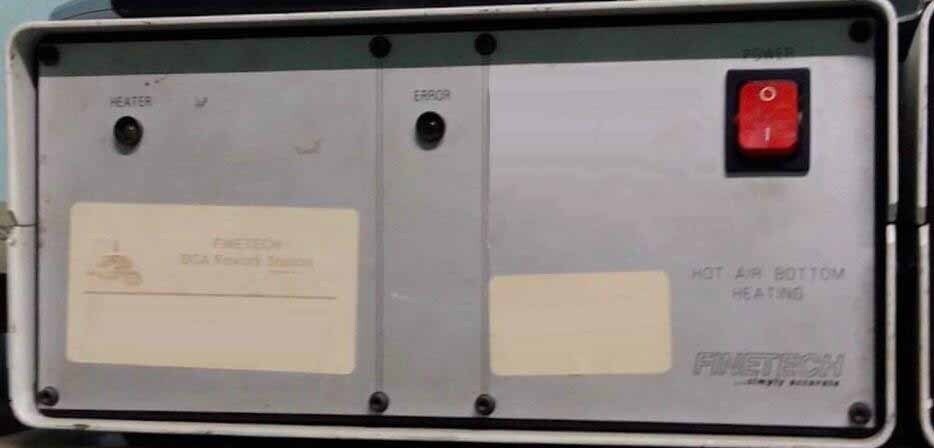

RB7 Hot air bottom heater

RA8-GS Reflow controller

DELL Monitor, 15".

FINETECH Fineplacer is a leading solution for automated single- and double-sided pc board assembly and manufacturing. With its superior placement accuracy, wide component variety, small footprint, and self-contained serviceability, Fineplacer offers the latest in advanced, efficient SMT production. FINETECH Fineplacer utilizes its high-end laser-guided vision equipment combined with the precision of its motion mechanics to accurately and reliably place components onto printed circuit boards. Furthermore, the system incorporates several additional features to streamline the process and reduce operator involvement and error. The unit consists of a PC-based platform with an intuitive graphical user interface (GUI) that allows operators to easily program, monitor, and control the installation of components on the printed circuit boards. Fineplacer can place both surface mount (SMT) and through-hole (THT) components, including the smallest 0201-type components to the largest SOIC and QFP packages. Furthermore, it offers a dual-rail gantry machine for maximum speed and accuracy, and a high-speed, dual-actuated nozzle tool that allows for fast simultaneous placement of components. The asset can also handle feeder strips for rapid loading of SMT components. The model also includes analyzers to aid the installation process, including a presence analyzer that verifies the presence of components, and a placement analyzer that verifies the precise location of the installed components. The equipment is also equipped with a vision-based fiducial view and verification system, which ensures that components are properly aligned and correctly oriented on the board. FINETECH Fineplacer can easily adjust to varying board sizes with its adjustable shuttle unit, and its universal mount tray machine allows it to accept and work with non-standard component sizes. Fineplacer is designed for easy maintenance and serviceability of its parts. It includes a user-friendly, self-monitoring maintenance tool and online diagnostics that help prevent and diagnose faults. Furthermore, it features an automatic nozzle cleaning asset that cleans the nozzles and feeders between jobs. Finally, the model can be customized with additional features such as board handling and defect detection systems. In short, FINETECH Fineplacer is the perfect solution for automated single- and double-sided pc board assembly and manufacturing. With its state-of-the-art features, superior precision, and easy serviceability, Fineplacer is the ideal option for optimizing SMT production.

There are no reviews yet